Floating wheel type water turbine

One-type water turbine, the technology of water turbine, applied in the direction of water wheel, reaction engine, mechanical equipment, etc., can solve the requirements of equipment manufacturing process and technical design, high manufacturing cost, buoyancy traction device occupying water area, blade water interception area is small, etc. problems, to achieve the effect of increasing the intercepting area of the flowing water, omitting the buoyancy traction device, and improving the conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

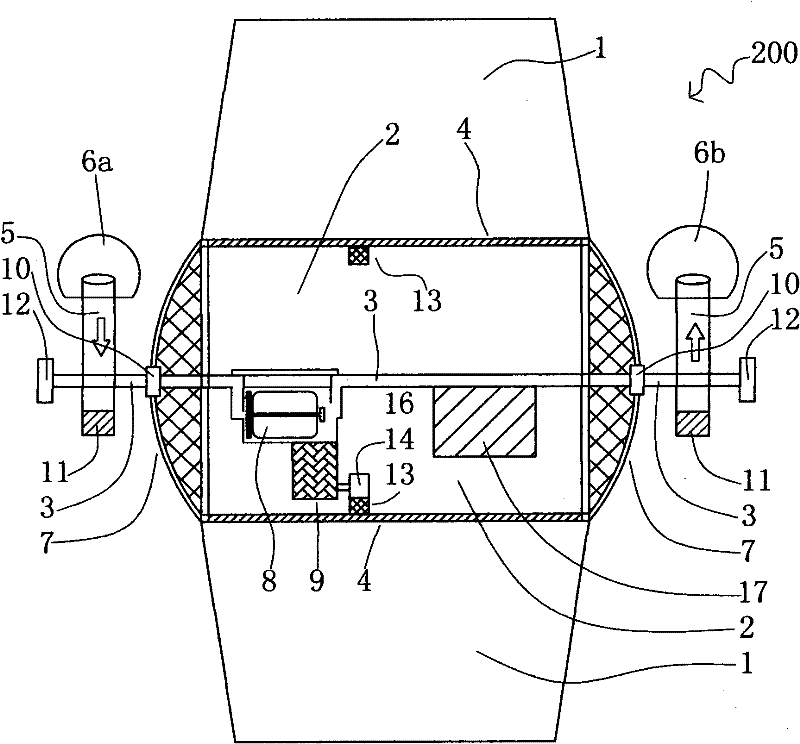

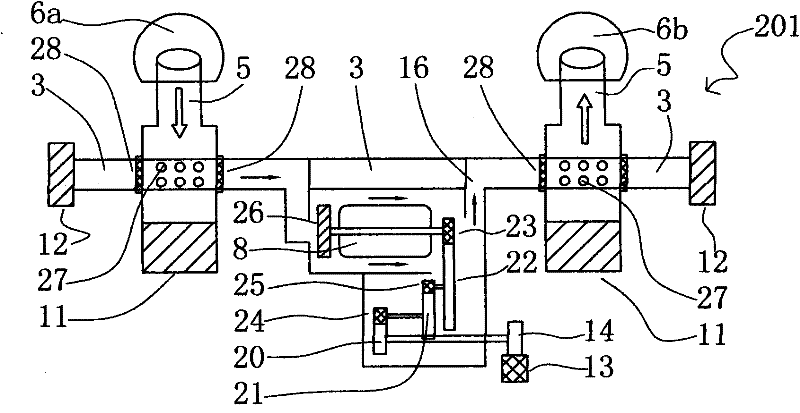

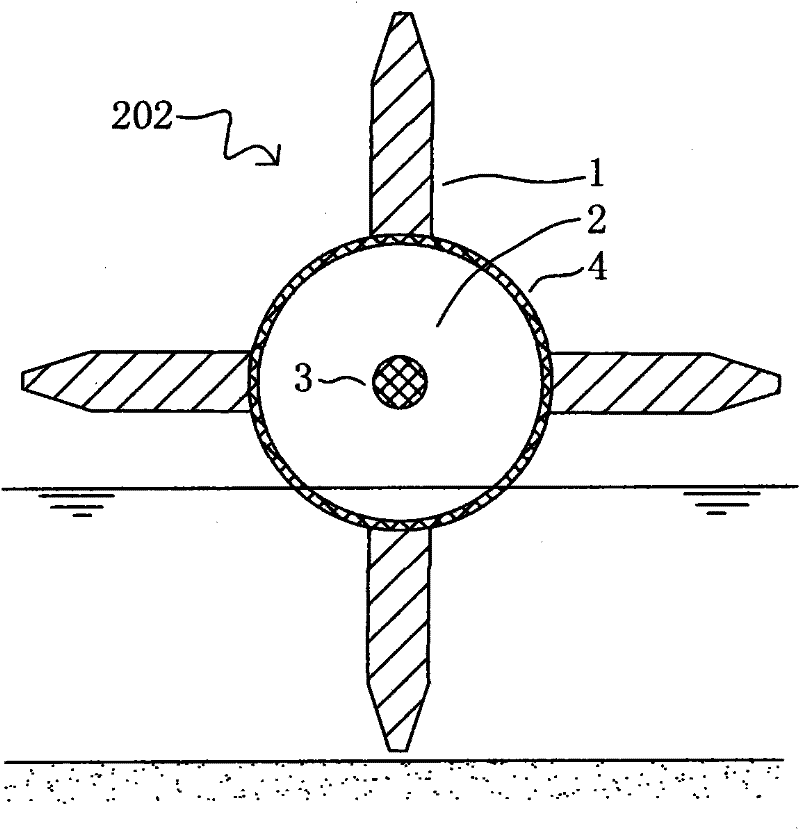

[0051] Figure 1 to Figure 14 It is an explanatory drawing of the built-in water turbine of this invention.

[0052] now refer to Figure 1 to Figure 14 .

[0053] image 3 It is the water wheel 202 of the present invention, including blade 1, buoy 2, shaft core 3 and housing 4; as Figure 5 As shown, in order to adapt to different water depths and facilitate the adjustment of the draft of the water wheel 202, the blades 1 are of modular design, respectively A, B, C, and D, and the last piece of A cut surface is conical; The slots are received and each module is fixed and integrated by bolts 37; the blade 1 is also provided with a plurality of independent sealed cavities 38, one of the purpose of setting the cavities 38 is to provide buoyancy support for the system, and its design principle is: taking into account the blade 1 One is that the cavity must be independent, so that even if a part of the cavity is damaged and leaks, the system will not be paralyzed; the other is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com