Five-degree-of-freedom (five-DOF) bearing-free permanent magnet synchronous motor

A permanent magnet synchronous motor, bearingless technology, applied in electrical components, electromechanical devices, holding devices using magnetic attraction or thrust, etc. The effect of axial space utilization efficiency, simplified structure, and shortened axial length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

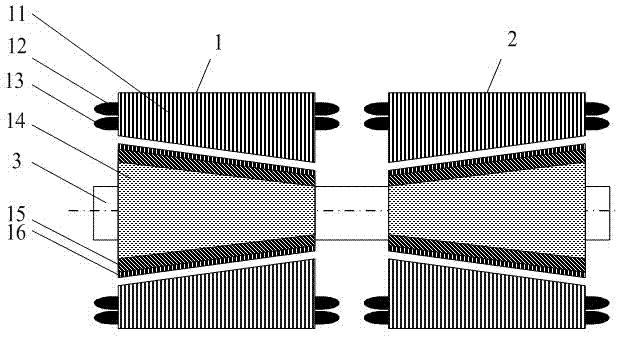

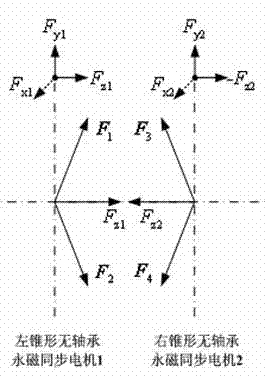

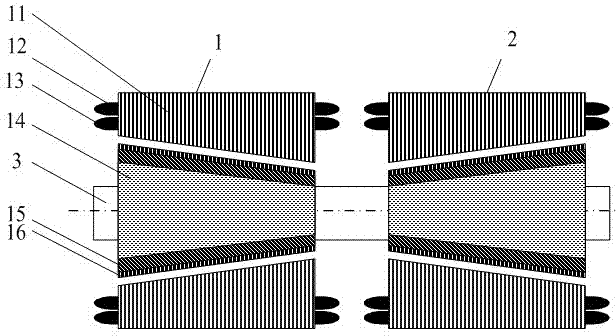

[0019] Such as figure 1 As shown, the five-degree-of-freedom bearingless permanent magnet synchronous motor includes a motor housing and a mechanical shaft 3, the mechanical shaft 3 passes through the left and right ends of the motor housing, and two identical The conical bearingless permanent magnet synchronous motors, namely the left conical bearingless permanent magnet synchronous motor 1 and the right conical bearingless permanent magnet synchronous motor 2, are symmetrically connected by a mechanical shaft 3. Each conical bearingless permanent magnet synchronous motor is composed of a conical stator 11 , a torque winding 12 , a levitation force winding 13 and a conical rotor 14 . The outer surface of the conical rotor 14 is mounted with a permanent magnet 15 made of permanent magnet material NdFeB. The outer surface of the permanent magnet 15 is fixed with a sheath 16 made of carbon fiber material. The conical rotor 14 is fixed on the mechanical shaft 3 The tapered stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com