Permanent magnet inner cylinder type polymetallic synchronous magnetic separator

A multi-metal and magnetic separator technology, applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of increasing the cost of mineral processing, unfavorable environmental protection, and large equipment footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

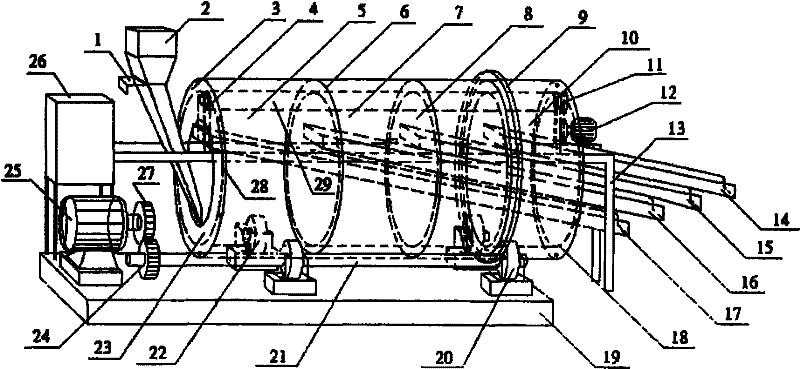

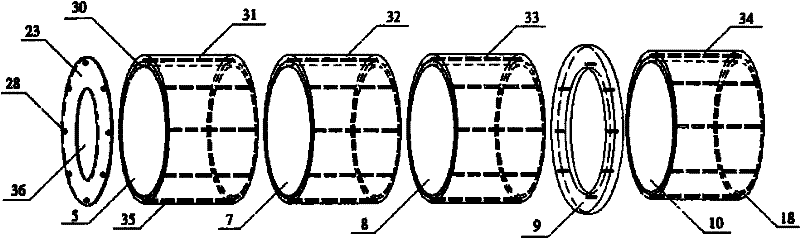

[0020] A permanent magnet inner cylinder multi-metal synchronous magnetic separator of the present invention will be further described in detail below in conjunction with the accompanying drawings, see the accompanying drawings.

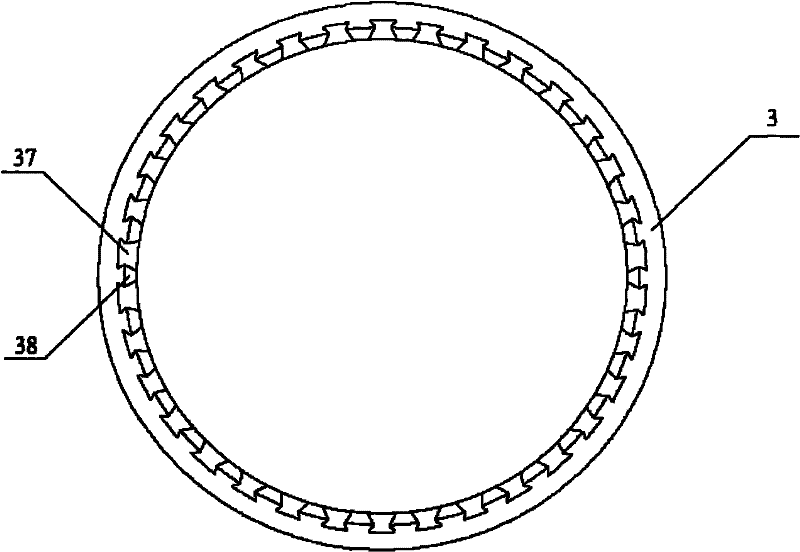

[0021]A kind of permanent magnet inner cylinder type multi-metal synchronous magnetic separator, it is made up of power motor, base 19, permanent magnet roller 3, support 13, control cabinet 26, feeding box 2, feeding chute, feeding roller 29 and The transmission part consists of a permanent magnet material 30 inlaid on the inner wall of the magnetic roller 3. The permanent magnet material 30 needs to be selected according to the requirements of the mineral processing parameters. Inlaid combination structure, the manufacturing process can adopt the structural technology in the Chinese patent publication number CN101406860, the title of the invention is: "High Gradient Strong Magnetic Field Horizontal Composite Magnetic Concentration Roller". The magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com