Self-cooling outer rotor motor

An external rotor motor and self-cooling technology, which is applied in the direction of cooling/ventilation devices, electromechanical devices, electrical components, etc., can solve the problems of reactive power loss, increased noise, larger motor volume, and difficult dynamic balance, etc. The effect of reducing power loss, simplifying the process, and improving assembly work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

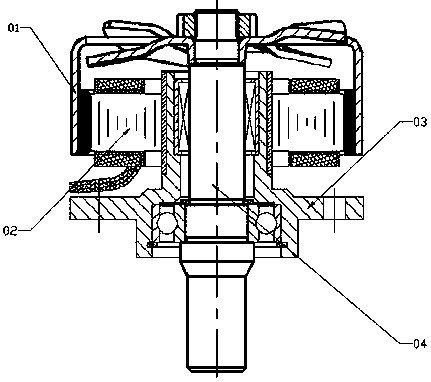

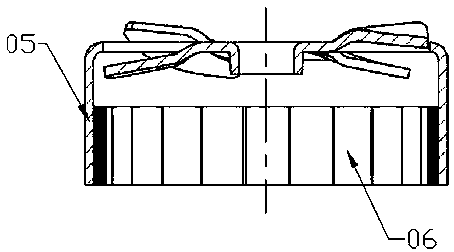

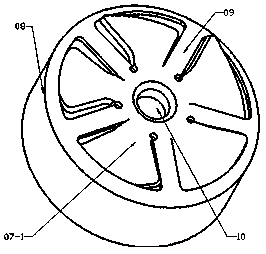

[0026] Such as Figure 1-4 , 9. A self-cooling external rotor motor, which is composed of a rotor support assembly 01, a stator assembly 02, a fixed frame assembly 03, and an output shaft assembly 04. The rotor support assembly 01 includes a rotor support 05 and a permanent magnetic steel 06, the magnetic steel 06 is adhered to the inner wall of the cavity of the rotor bracket 05, and the magnetic steel 06 is connected with the stator assembly 02 in a gap. The rotor bracket includes an outer cylinder 08 and an end cover 09, and the end cover 09 is arranged at one end of the outer cylinder 08. A rotating shaft hole 10 is provided in the middle of the end cover 09, and a number of blades 07-1 are hollowed out on the end cover 09, and the blades 07-1 are evenly distributed on the outer periphery of the rotating shaft hole 10, and the hollowed-out end cover 09 and the outer cylinder 08 together constitute an axial flow fan; there is a gap between the rotor bracket 05 and the fixed...

specific Embodiment 2

[0027] Such as Figure 1-2 , 5-6, 9, further improved on the basis of specific embodiment 1, the end cover 09 and the blade 07-2 are integrally precision casted, and one side of the blade 07-2 is connected to the end cover 09, and the blade 07-2 The other side is located inside the inner cavity of the outer cylindrical body 08 .

specific Embodiment 3

[0028] Such as Figure 1-2 , 7-9, further improved on the basis of specific embodiment 1, the end cover 09 and the blade 07-3 are integrally precision casted, one end of the blade 07-3 is connected to the shaft hole 10, and the other end of the blade 07-3 is connected to the outer The cylinder body 08, one side of the blade 07-3 is located inside the inner cavity of the outer cylinder 08, and one side of the blade 07-3 is located outside the inner cavity of the outer cylinder 08.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com