High-pressure washer driving system and method based on brushless direct current motor

A brushed DC motor and high-pressure cleaner technology, applied in liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve output pressure and flow limitations, low efficiency and low efficiency of high-pressure cleaners, etc. problem, to achieve the effect of reducing reactive power loss, improving efficiency, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

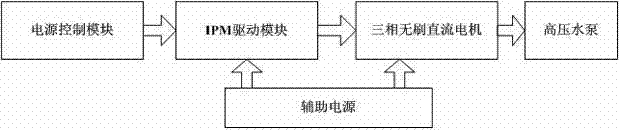

[0037] like figure 1 As shown, a brushless DC motor-based high-pressure washer drive system, including

[0038] The power control module is used for external AC power supply, and outputs DC voltage after EMI filtering, rectification and power factor compensation;

[0039] The IPM drive module is used to control the speed of the three-phase brushless DC motor;

[0040] Three-phase brushless DC motor, used to output power to the high-pressure water pump;

[0041] The power control module outputs a high-voltage DC voltage to the IPM drive module, and the IPM drive module controls the three-phase brushless DC motor to output power to the high-pressure water pump.

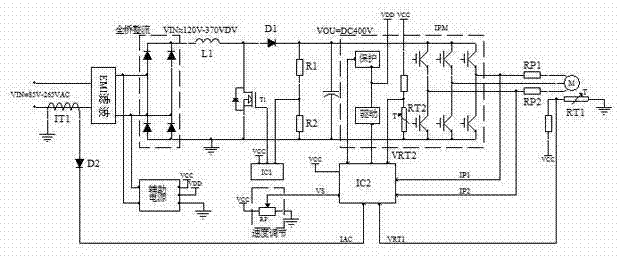

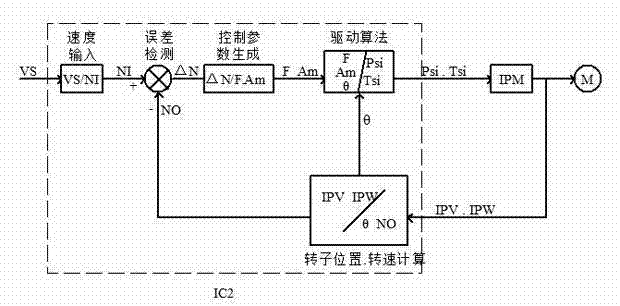

[0042] like figure 2As shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com