Oil pumping machine

A technology of pumping unit and sucker rod, which is applied in the direction of using electric mode for temperature control, production of fluid, drilling equipment, etc., can solve the problems of low mechanical efficiency, difficult pumping unit, large process energy consumption, etc. Control and network control, reduction of reactive power loss, highly targeted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

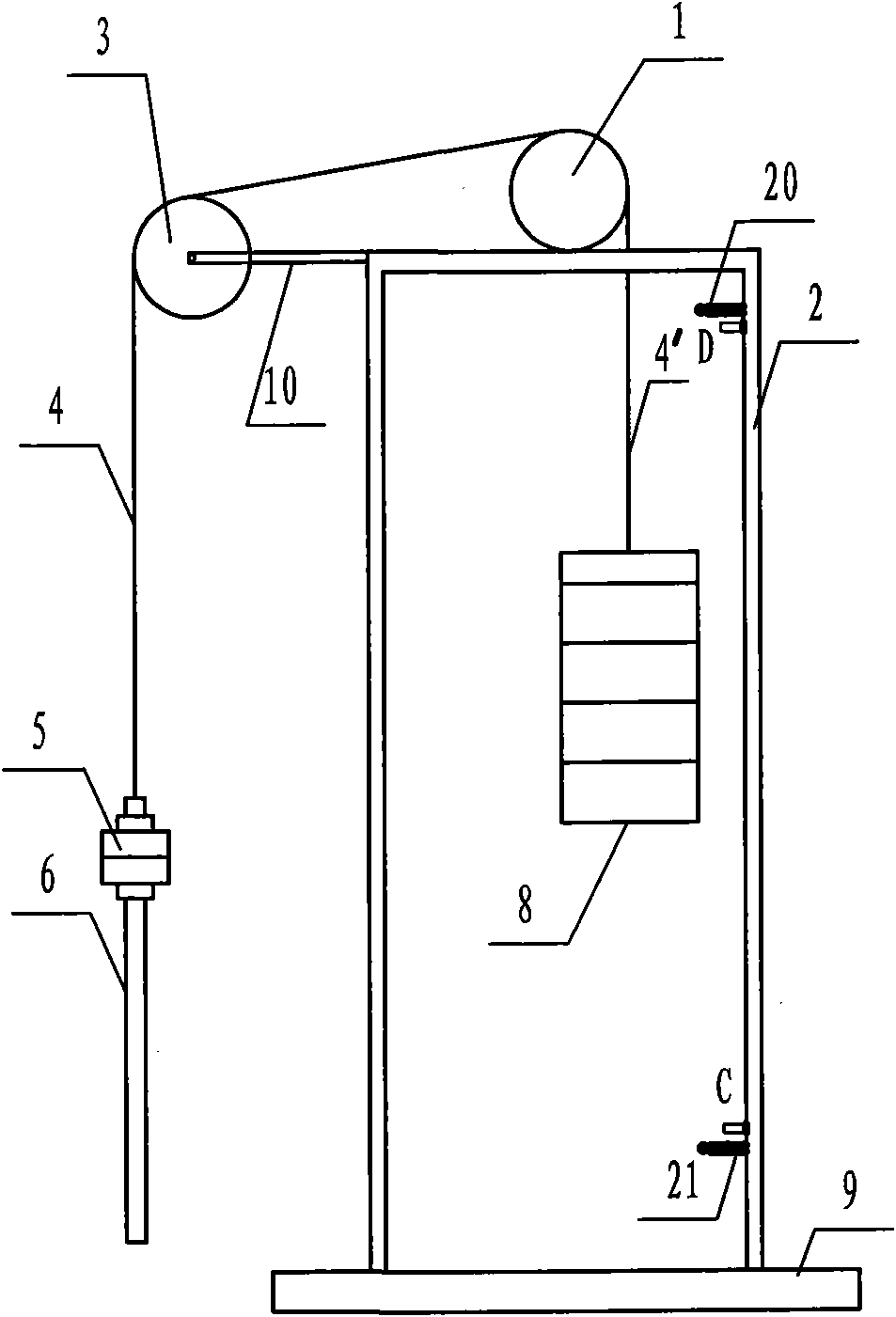

[0060] figure 1 Shown is a pumping unit, which includes a fixed drive host 1 , a tower 2 fixed on a foundation 9 , and a first sucker rod 6 driven by the drive host 1 .

[0061] The driving host 1 is a permanent magnet synchronous reducer, and it is an upper-mounted type relative to the tower 2: that is, the driving host 1 is fixed on the top and middle of the tower 2, and the combined counterweight 8 is located in the tower 2 and is set at the lower part of the driving host 1 and is biased to the outside. The top edge of the opposite side of the side where the counterweight 8 is located on the tower 2 is fixed with a guide wheel support 10 extending outwards, and the axle of the wire rope guide wheel 3 is fixedly hinged on the guide wheel support 10; The host 1 is provided with a wire rope reel driven by the output shaft of the drive host 1, and two wire ropes 4 and 4' are wound on the wire rope reel, one end of which is respectively fixed on the wire rope drum, and their fre...

Embodiment 2

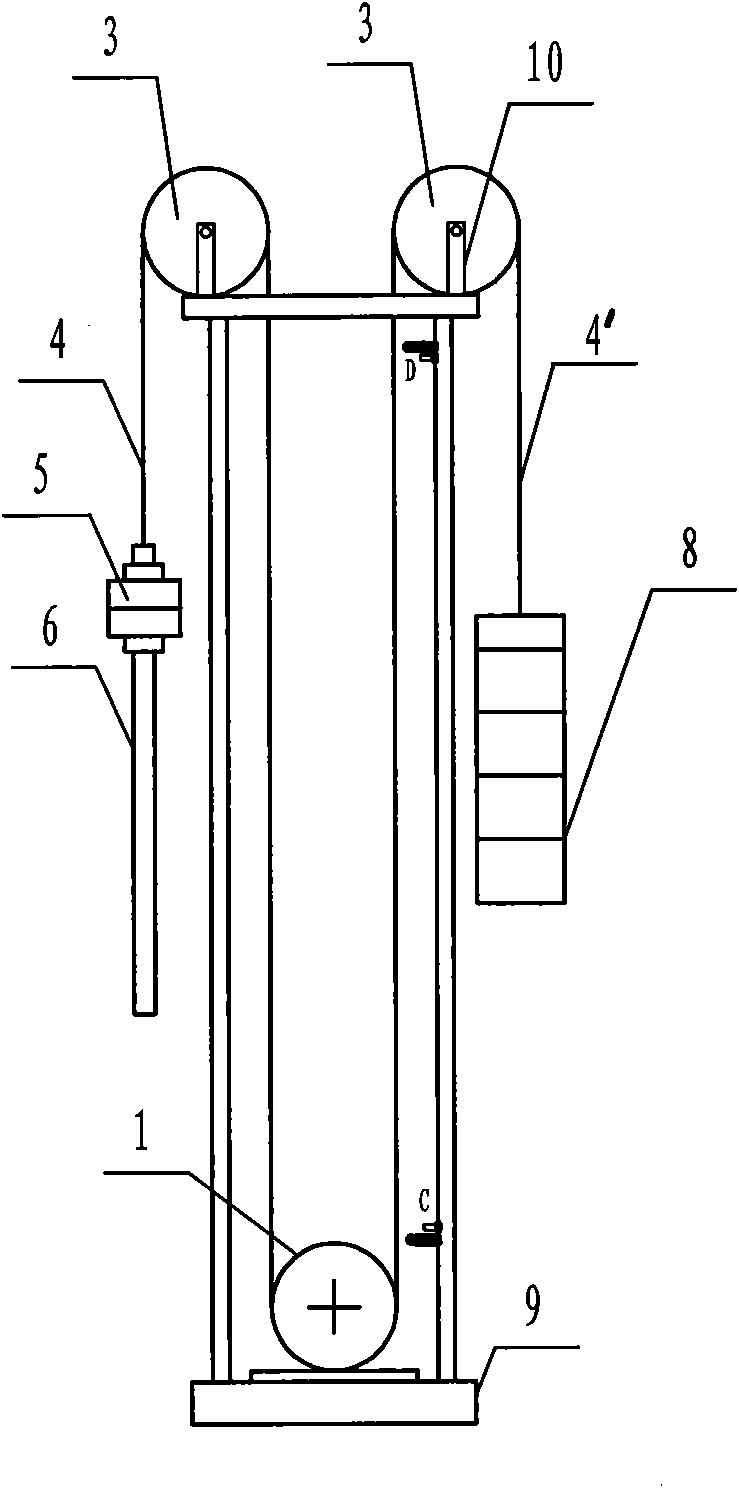

[0096] The difference between the present embodiment and the first embodiment is only that the distribution of the driving host 1 and the tower 2 is different, and the structure of other parts is the same as that of the first embodiment.

[0097] In this embodiment, the drive host 1 is a lower-mounted type relative to the tower 2, refer to figure 2 The driving host 1 is fixed on the foundation 9 below the tower frame 2; the two side edges corresponding to the top of the tower frame 2 corresponding to the top of the driving host 1 are respectively fixed with guide wheel brackets 10, and the axles of the wire rope guide wheels 3 are fixed and hinged to the guide on the wheel bracket 10; two wire ropes 4 and 4' are wound on the wire rope reel, one end of which is respectively fixed on the wire rope reel, and their free ends are fixed and hinged to the wire rope guide wheel 3 on the tower through the wheel axle. The first sucker rod 6 and the combined counterweight 8 are connecte...

Embodiment 3

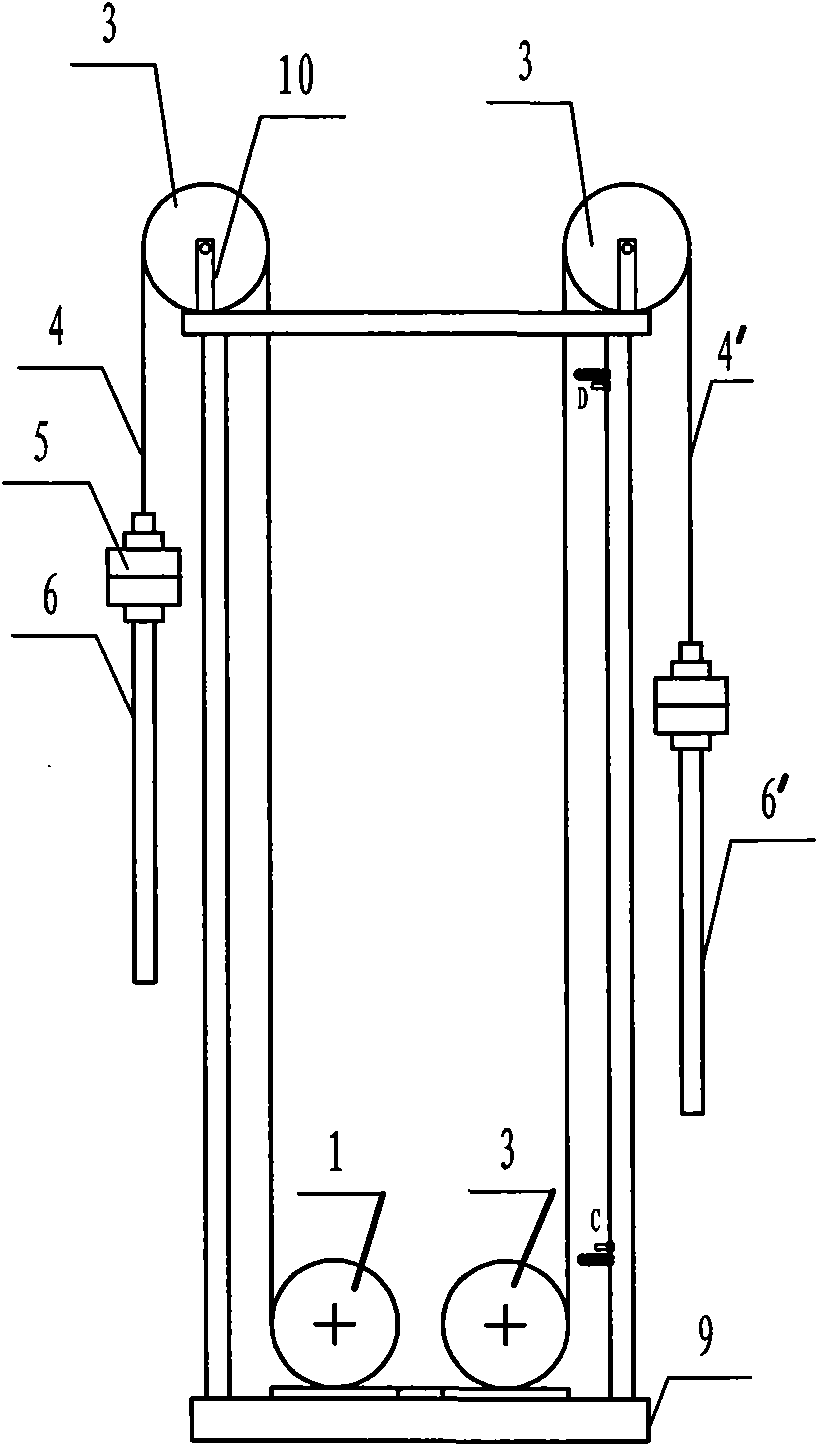

[0099] The difference between this embodiment and the second embodiment is only that the distribution of the drive host 1 and the tower 2 is different, and the structure of other parts is the same as that of the first embodiment.

[0100] In this embodiment, the drive host 1 is a lower-mounted type relative to the tower 2, refer to image 3 : the driving host 1 is fixed on the foundation 9 below the tower frame 2, and the foundation 9 is also provided with a wire rope guide wheel arranged in parallel with the driving host 1; the combined counterweight 8 and the second sucker rod 6 in the first embodiment 'Replacement; at the top of the tower 2 corresponding to the two side edges of the top of the drive main frame 1, guide wheel brackets 10 are respectively fixed, and the axle of the wire rope guide wheel 3 is fixedly hinged on the guide wheel bracket 10; on the wire rope reel, there are two Steel wire ropes 4 and 4′, one end of which is respectively fixed on the wire rope reel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com