Biomass molding machine with annular tooth-shaped mold

A biomass forming machine and tooth-shaped technology, which is applied in the direction of material forming presses, presses, manufacturing tools, etc., can solve the problems of short service life of key components, low production capacity of forming machines, high failure rate, etc., and achieve overall performance improvement , Adaptability enhancement, and the effect of reducing the degree of wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

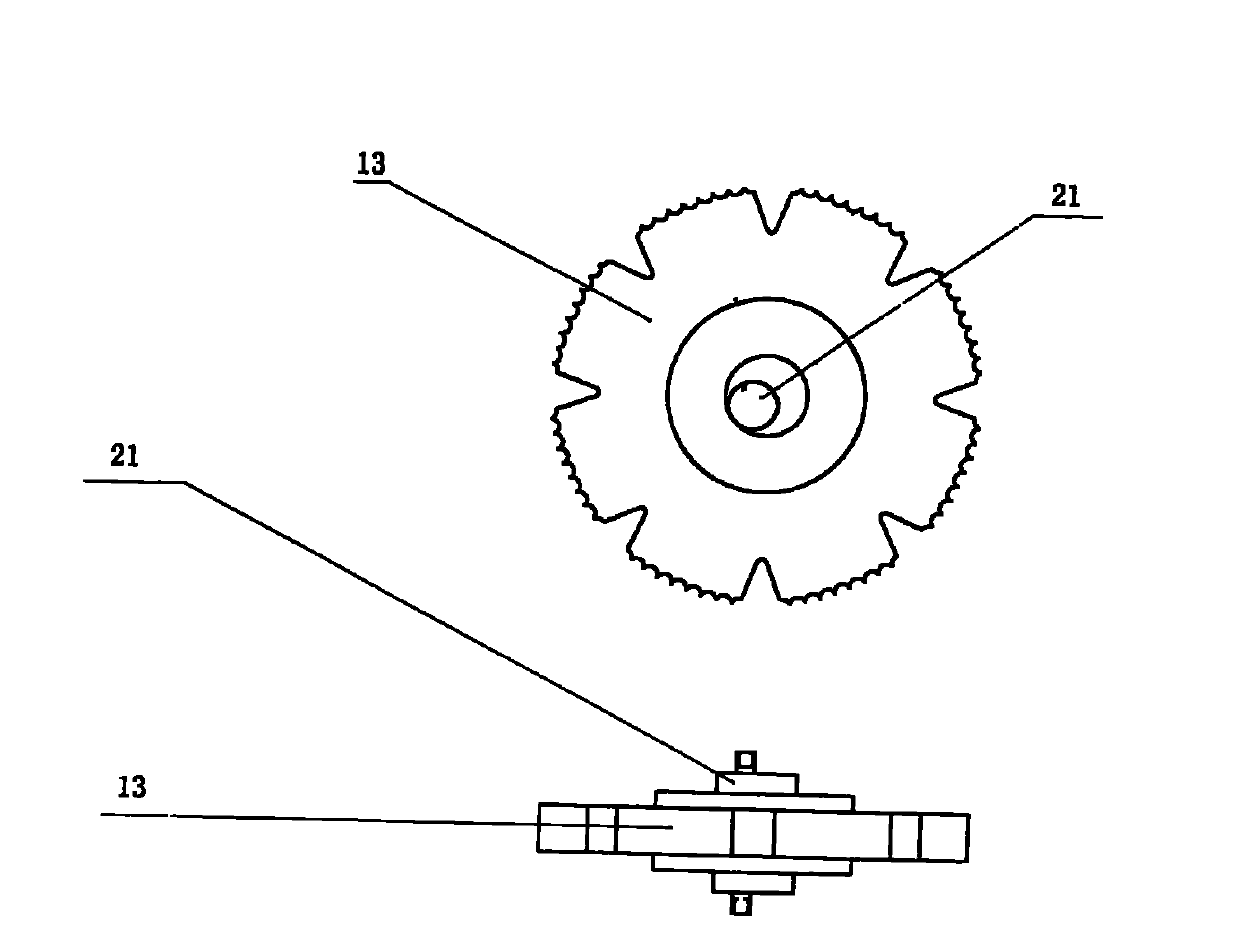

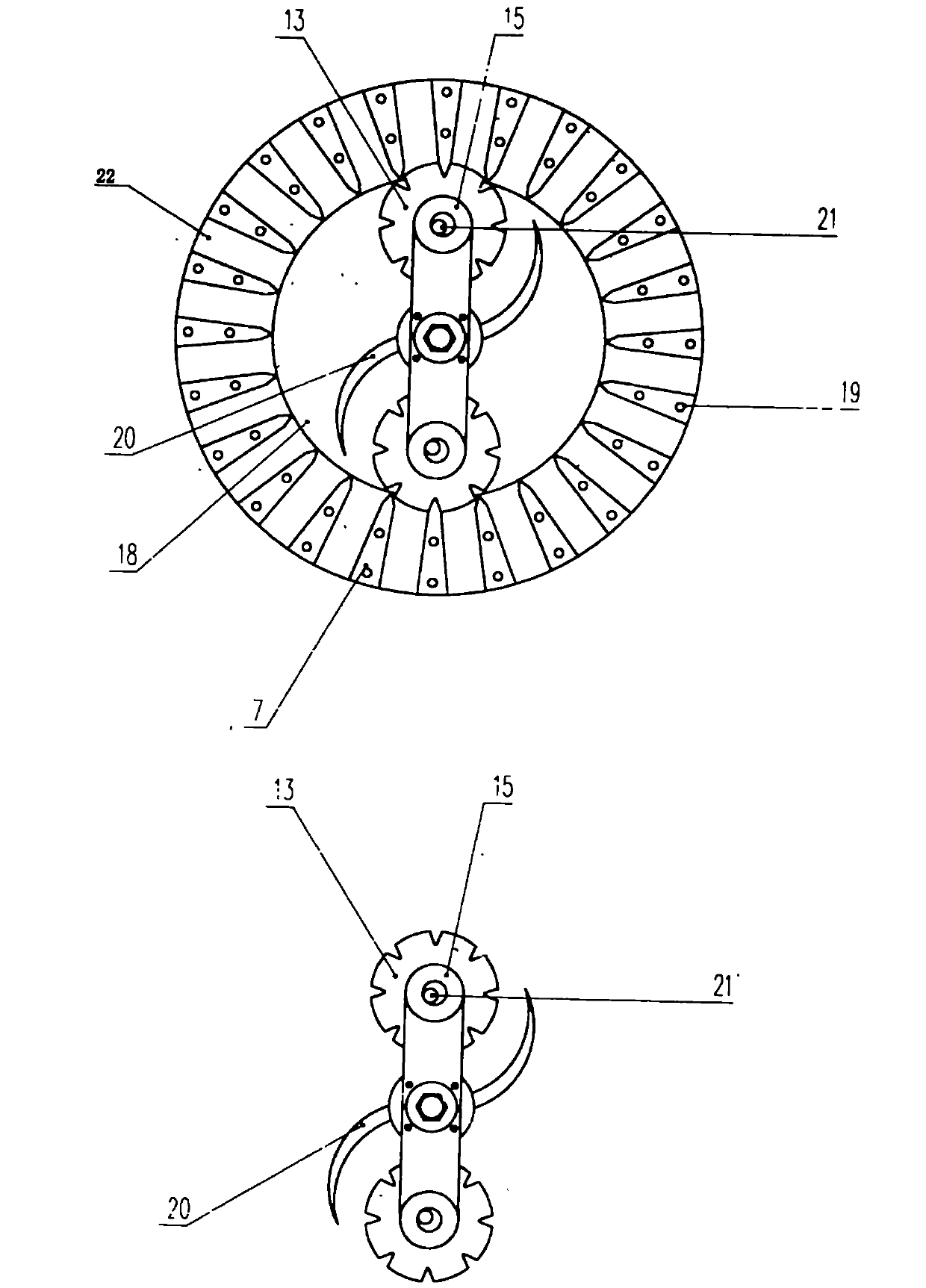

[0011] The forming process of the tooth-shaped mold biomass forming machine of the present invention: first start the motor for trial operation for 1-2 minutes. The raw materials are added manually or by a conveyor, and the toothed pressing roller [13] and the annular toothed die [7] are driven by the power pulley [1] through the main transmission shaft [3] toothed pressing roller assembly [15]. Synchronous rolling is done in the way of gearing. At this time, the raw materials entering the molding cavity [18] are evenly distributed in the forming holes of the ring tooth mold [attachment] through the action of the equalizing plate Figure 4 .4], due to the continuous operation of the toothed pressure roller [13], the raw material is pressed into the forming hole by the toothed pressure roller [13] [attached Figure 4 .4], the toothed pressure roller is continuously running and the raw material is continuously pressed into the forming hole until it passes through the forming hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com