Copper tube and electric furnace energy-saving noninductive short net

A copper tube and short network technology, applied in circuits, electrical components, reactive power compensation, etc., can solve the problems of low natural power factor, high impedance, and high unit power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

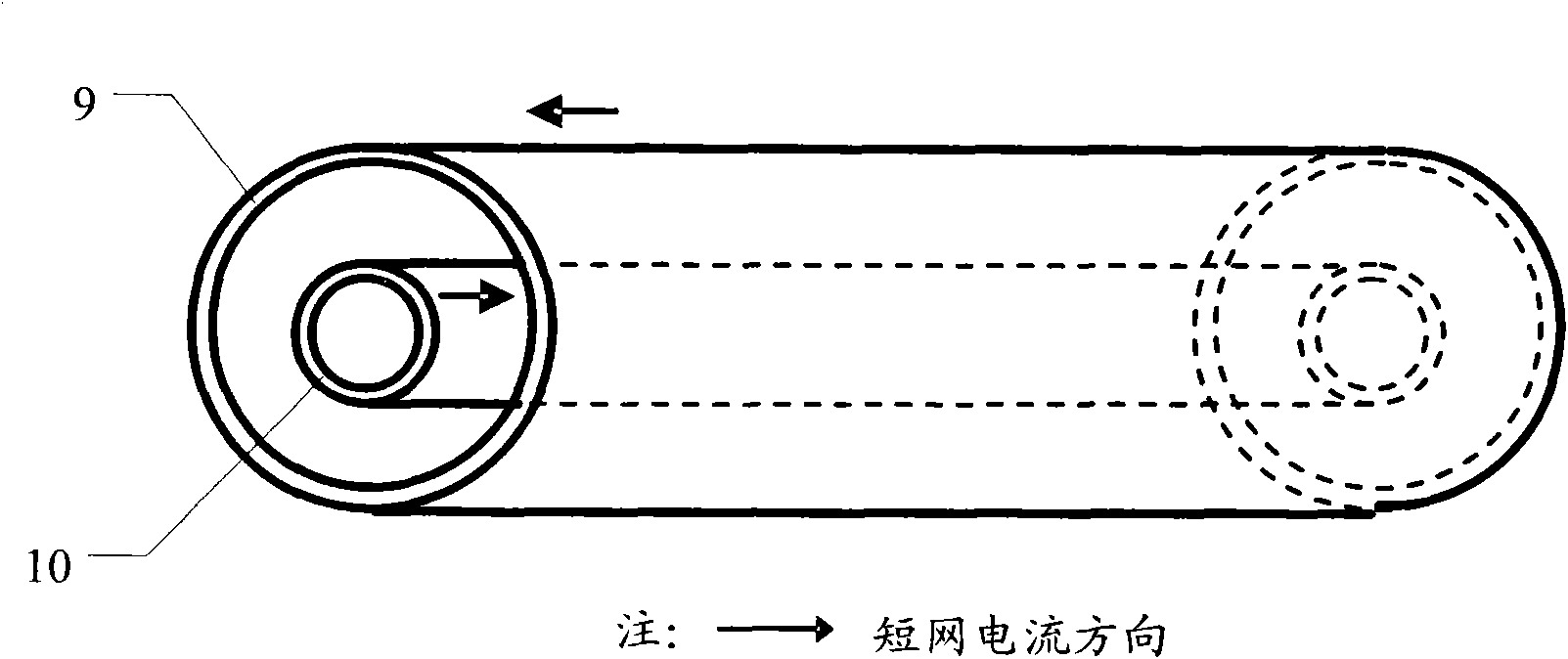

[0028] According to an embodiment of the present invention, a copper pipe is provided. Such as image 3 As shown, this embodiment includes a first conductor 10 and a second conductor 9, and the second conductor 9 is axially sleeved on the periphery of the first conductor 10; between the first conductor 10 and the second conductor 9, filled with first Insulation layer: the outer periphery of the second conductor 9 is coated with a third insulation layer.

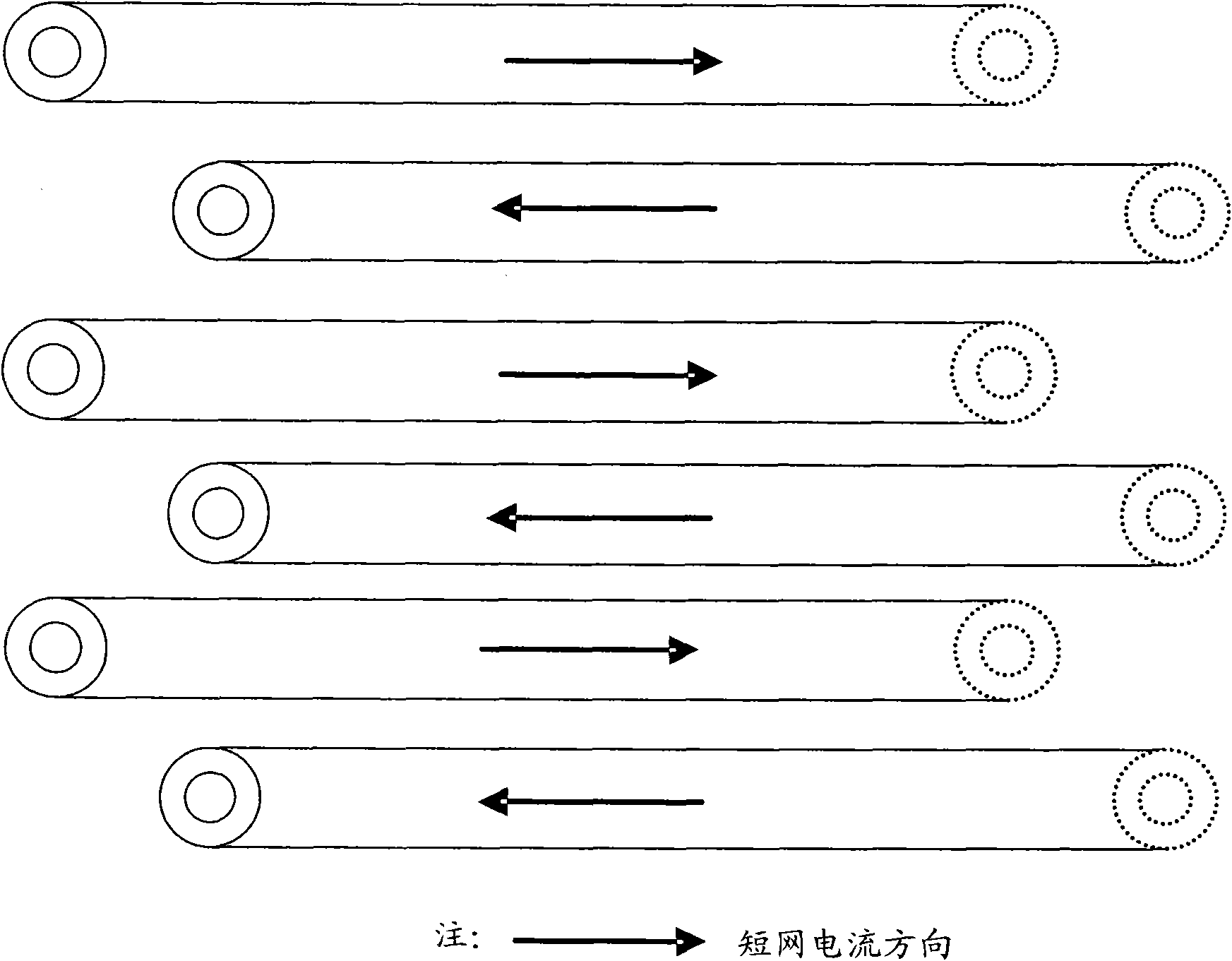

[0029] In this embodiment, the distance between the first conductor 10 and the second conductor 9 is relatively short, the flow direction of the short-circuit current in the first conductor 10 is opposite to the flow direction of the short-circuit current in the second conductor 9, and the short-circuit current in the first conductor 10 The electric field and the direction of the magnetic field produced by the short-circuit current are opposite to the electric power plant and the direction of the magnetic field produced by t...

Embodiment 2

[0031] Different from the above embodiment, in this embodiment, if Figure 4 As shown, the copper tube includes a first conductor 10, a second conductor 9 and a capacitor 8, wherein the second conductor 9 is axially nested on the periphery of the first conductor 10, and the capacitor 8 is axially nested on the periphery of the second conductor 9 ; The first insulator is filled between the first conductor 10 and the second conductor 9, the second insulator is filled between the second conductor 9 and the capacitor 8, and the periphery of the capacitor 8 is covered with a fourth insulating layer.

[0032] In this embodiment, the capacitor 8 is axially sleeved on the periphery of the second conductor 9, which can further reduce the inductance and impedance of the copper tube, so as to further reduce the reactive power loss of electric energy on the copper tube and increase the active power. power.

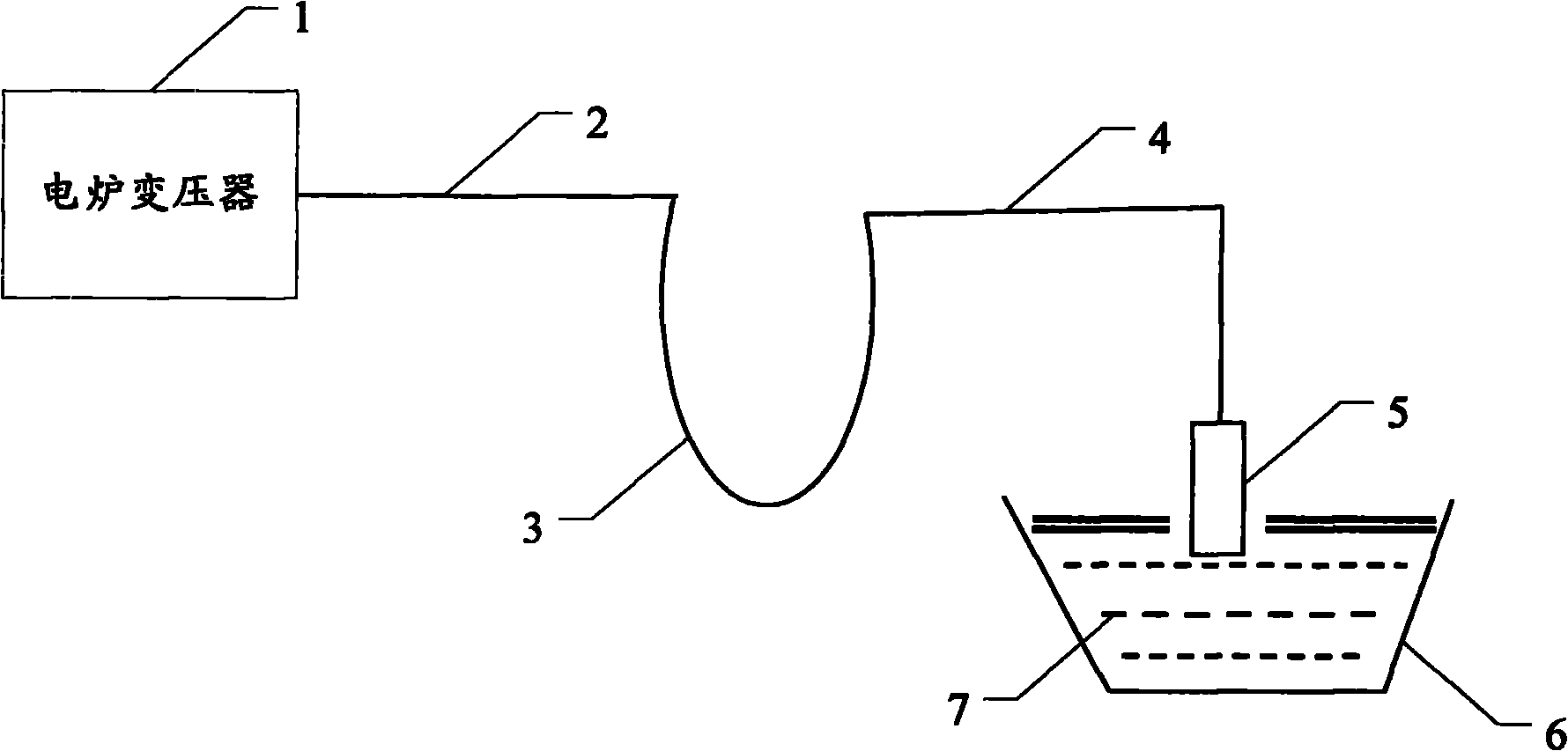

[0033] Electric furnace energy-saving non-inductive short network embodiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com