A high-strength and corrosion-resistant 5383 aluminum alloy and a preparation process for marine profiles

A preparation process and aluminum alloy technology, which is applied in the field of high-strength and corrosion-resistant 5383 aluminum alloy and marine profile preparation process, can solve the problems that cannot meet the application requirements of marine materials, the price of rare earth elements is expensive, and the dimensional accuracy is difficult to control. Strong corrosion resistance, good corrosion resistance, good processability and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

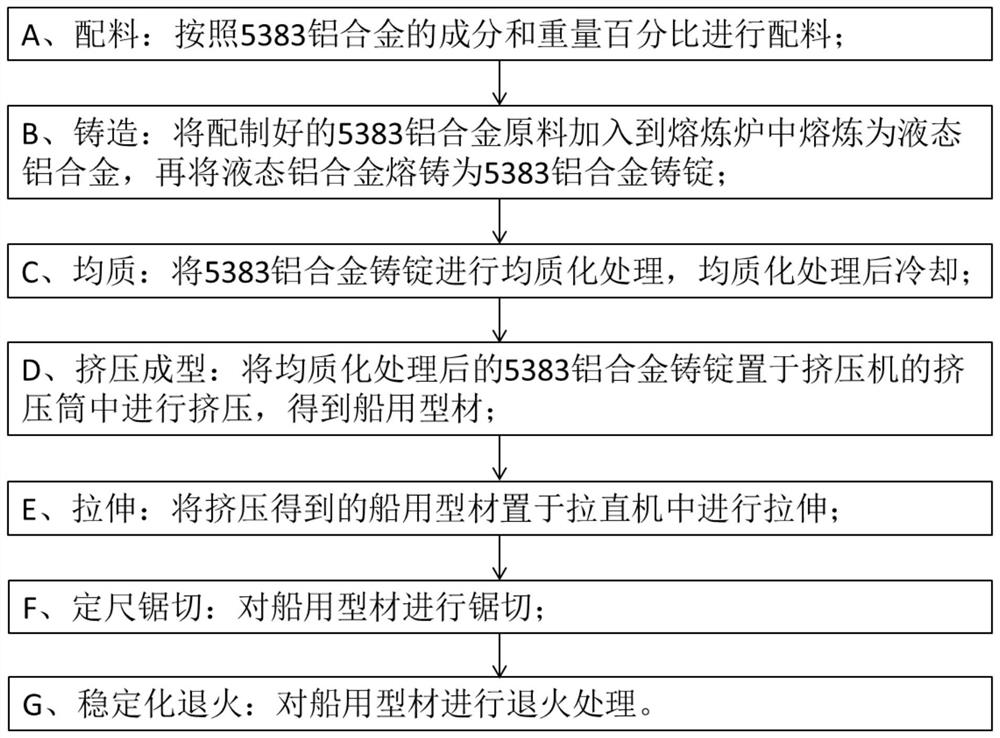

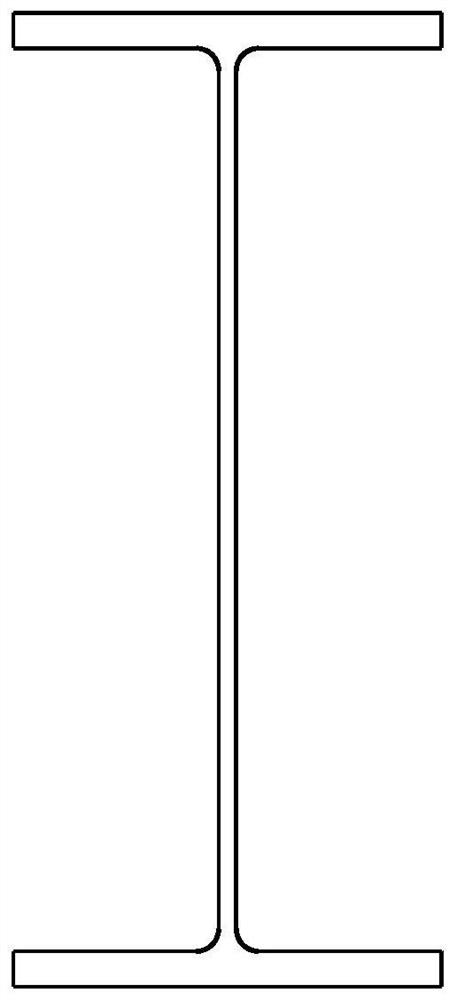

[0037] See figure 1 , a marine profile preparation process, which mainly includes:

[0038] Calculate the amount of 5383 aluminum alloy raw materials, and prepare the aluminum alloy raw materials according to the ratio. The mass percentage ratio of each element of the 5383 aluminum alloy raw materials is as follows:

[0039] element Si Fe Cu mn Mg Cr Zn Ti Zr Impurities Al content 0.12 0.18 0.07 0.88 4.6 0.05 0.33 0.03 0.12 0.15 margin

[0040] B. Casting: Add the prepared 5383 aluminum alloy raw materials into the smelting furnace and mix them evenly to melt into liquid aluminum alloy. The water-cooled casting method melts and casts 5383 aluminum alloy ingots with a round rod structure;

[0041] C. Homogenization: Homogenize the 5383 aluminum alloy ingot, specifically, adopt two-stage soaking, the first-stage soaking temperature is 410°C, the holding time is 10h, and the second-stage soaking temperature is 510°C , the holdi...

Embodiment 2

[0047] The difference between embodiment 2 and embodiment 1 is that the mass percentage ratio of each element of the 5383 aluminum alloy raw material in step A is as follows:

[0048] element Si Fe Cu mn Mg Cr Zn Ti Zr Impurities Al content 0.12 0.18 0.06 0.75 4.3 0.05 0.29 0.03 0.09 0.15 margin

Embodiment 3

[0050] The difference between embodiment 3 and embodiment 1 is that the mass percentage ratio of each element of the 5383 aluminum alloy raw material in step A is as follows:

[0051] element Si Fe Cu mn Mg Cr Zn Ti Zr Impurities Al content 0.12 0.18 0.06 0.90 4.8 0.05 0.37 0.03 0.15 0.15 margin

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com