Degradable modified polyester with high heat resistance and good mechanical properties and preparation method thereof

A modified polyester, high heat resistance technology, applied in the field of degradable polyester and its preparation, can solve the problems of refractory degradation, reduced elongation at break, low glass transition temperature, etc., achieve good mechanical properties, accelerate degradation The effect of speed and good hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

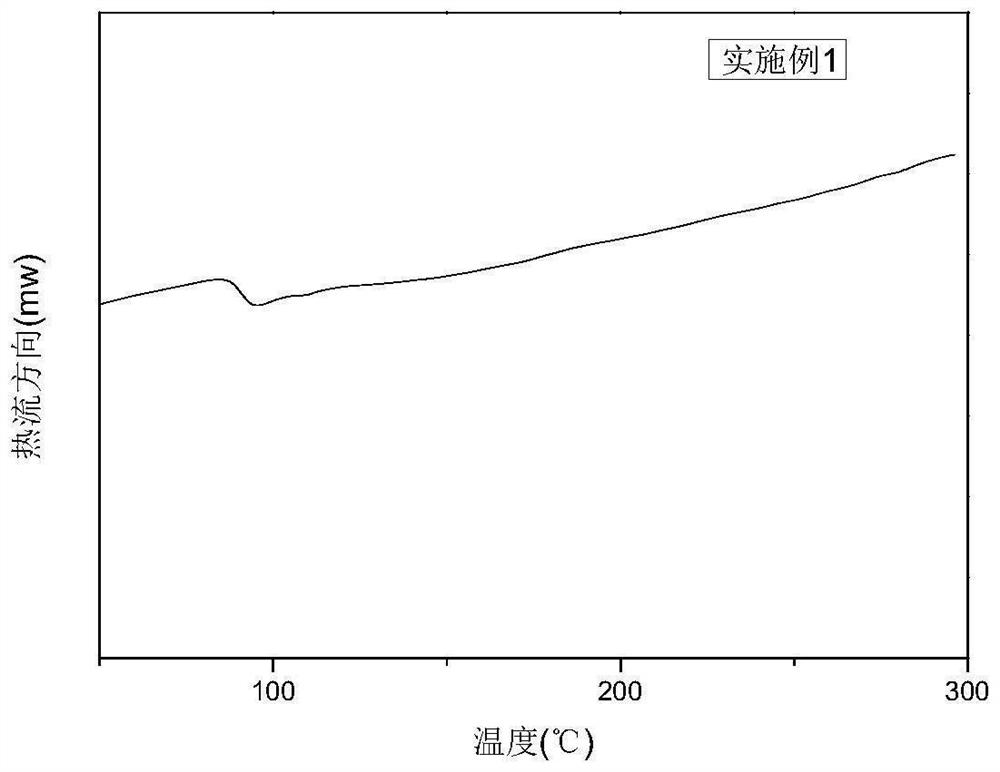

Embodiment 1

[0031]First, the reactor is preheated, and the preheating temperature of the reactor is set to 100°C. When the temperature in the reactor reaches 50°C, 300g of terephthalic acid, 143.3g of ethylene glycol, 76.7g of isosorbide, and Put alcohol 6.2g, catalyst antimony trioxide 80mg, antioxidant [1010] 500mg, triphenyl phosphate 100mg into the reaction kettle, and set the speed of the stirring paddle at 10r / min. During the stirring process, carry out nitrogen replacement at the same time (inflate nitrogen to 150Kpa, keep the pressure for 10s, slowly release the pressure to normal pressure, usually replace 3-5 times). Then, when the temperature in the reactor rose to 100°C, the rotation speed of the stirring paddle was gradually increased, finally to 50r / min. Under the condition of stirring paddle rotation speed 50r / min, firstly fill nitrogen to 150Kpa, then raise the set temperature of the reactor from 100°C to 230°C, and carry out pressure esterification of raw materials under n...

Embodiment 2

[0033] First, preheat the reactor, and set the preheating temperature of the reactor to 100°C. When the temperature in the reactor reaches 50°C, add 300g of terephthalic acid, 143.3g of ethylene glycol, 75g of isosorbide, and hexanediol 7.58g and 80mg of catalyst antimony trioxide, 500mg of antioxidant [1010], and 100mg of triphenyl phosphate were put into the reaction kettle, and the rotation speed of the stirring paddle was set at 10r / min. During the stirring process, carry out nitrogen replacement at the same time (inflate nitrogen to 150Kpa, keep the pressure for 10s, slowly release the pressure to normal pressure, usually replace 3-5 times). Then, when the temperature in the reactor rose to 100°C, the rotation speed of the stirring paddle was gradually increased, finally to 50r / min. Under the condition of stirring paddle rotation speed 50r / min, firstly fill nitrogen to 150Kpa, then raise the set temperature of the reactor from 100°C to 230°C, and carry out pressure esteri...

Embodiment 3

[0035] First, preheat the reaction kettle, and set the preheating temperature of the reaction kettle to 100°C. When the temperature in the reaction kettle reaches 50°C, 300g of terephthalic acid, 143.3g of ethylene glycol, 72.3g of isosorbide, and Put alcohol 9.8g, catalyst antimony trioxide 80mg, antioxidant [1010] 500mg, triphenyl phosphate 100mg into the reaction kettle, and set the speed of the stirring paddle at 10r / min. During the stirring process, carry out nitrogen replacement at the same time (inflate nitrogen to 150Kpa, keep the pressure for 10s, slowly release the pressure to normal pressure, usually replace 3-5 times). Then, when the temperature in the reactor rose to 100°C, the rotation speed of the stirring paddle was gradually increased, finally to 50r / min. Under the condition of stirring blade rotation speed of 50Hz, nitrogen gas is firstly charged to 150Kpa, and then the set temperature of the reactor is increased from 100°C to 230°C, and the raw materials are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com