A kind of antistatic eva foam composite material and preparation method thereof

A composite material and antistatic technology, which is applied in the field of polymer composite foam material preparation, can solve the problems of low bond strength between the coating and the polymer matrix resin, easy thermal decomposition, high cost, etc., and achieve extensive social and economic benefits and strategic value, beneficial to uniform dispersion, and the effect of reducing the coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

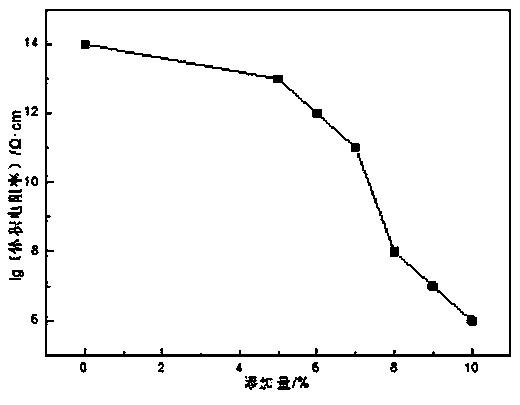

[0031] A method for preparing antistatic EVA foam composite material, the concrete steps are:

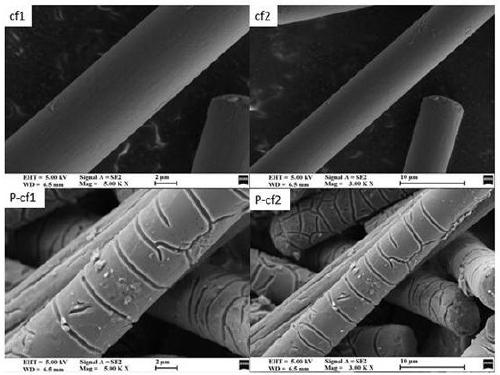

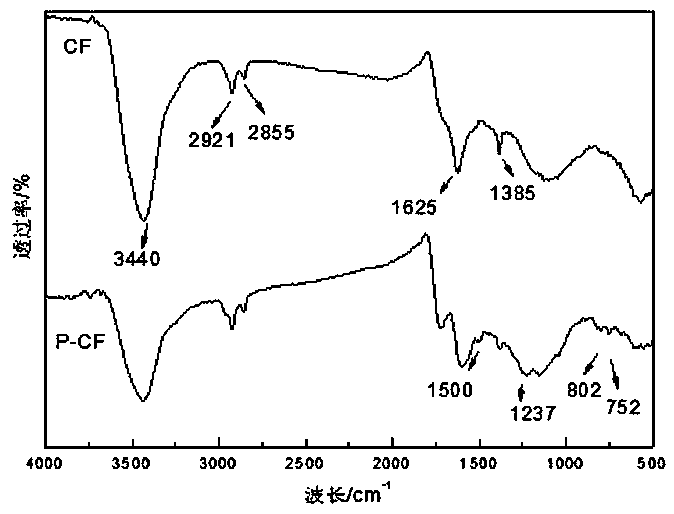

[0032] 1) Put the carbon fiber in a Soxhlet extractor and extract it with acetone solution for 12 h to remove the pulp and impurities remaining on the fiber surface, then wash it with deionized water for 5 times, and dry it in a blast drying oven at 80°C for 24 h ;

[0033] 2) Add 1.80 g of carbon fibers treated in step 1) into 1 mol / L hydrochloric acid solution, and stir at room temperature for 0.5 h to obtain a uniformly dispersed carbon fiber suspension;

[0034] 3) Add 0.0385 g of sodium lauryl sulfate to the carbon fiber suspension obtained in step 2), and ultrasonically disperse in a 100 W ultrasonic cleaner for 1 h;

[0035] 4) Add 2.1 mL of aniline monomer to the dispersion obtained in step 3), stir for 0.5 h, and keep the temperature in an ice bath for 0.5 h; put 3.4325 g of ammonium persulfate and 10 mL of deionized water into a constant pressure dropping funnel, Control...

Embodiment 2

[0040] A method for preparing antistatic EVA foam composite material, the concrete steps are:

[0041] 1) Put the carbon fiber in a Soxhlet extractor and extract it with acetone solution for 10 hours to remove the pulp and impurities remaining on the surface of the fiber, then wash it with deionized water 4 times, and dry it in a blast drying oven at 80°C for 24 hours;

[0042] 2) Add 1.80 g of carbon fibers treated in step 1) into 1 mol / L hydrochloric acid solution, and stir at room temperature for 0.5 h to obtain a uniformly dispersed carbon fiber suspension;

[0043] 3) Add 0.0385 g of sodium lauryl sulfate to the carbon fiber suspension obtained in step 2), and ultrasonically disperse in a 100 W ultrasonic cleaner for 1 h;

[0044] 4) Add 4.2 mL of aniline monomer to the dispersion obtained in step 3), stir for 0.5 h, and keep the temperature in an ice bath for 0.5 h; put 6.865 g of ammonium persulfate and 10 mL of deionized water in a constant pressure dropping funnel, C...

Embodiment 3

[0049] A method for preparing antistatic EVA foam composite material, the concrete steps are:

[0050] 1) Put the carbon fiber in a Soxhlet extractor and extract it with acetone solution for 14 h to remove the pulp and impurities remaining on the fiber surface, then wash it with deionized water three times, and dry it in a blast drying oven at 80°C for 24 h;

[0051] 2) Add 1.80g of carbon fibers treated in step 1) into 2mol / L hydrochloric acid solution, and stir at room temperature for 0.5h to obtain a uniformly dispersed carbon fiber suspension;

[0052] 3) Add 0.0385 g of sodium lauryl sulfate to the carbon fiber suspension obtained in step 2), and ultrasonically disperse in a 100 W ultrasonic cleaner for 1 h;

[0053] 4) Add 8.4 mL of aniline monomer to the dispersion obtained in step 3), stir for 0.5 h, and keep the temperature in an ice bath for 0.5 h; put 13.729 g of ammonium persulfate and 10 mL of deionized water in a constant pressure dropping funnel, Controlled 0.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com