Potassium-barium glass for lens, and preparation method and application thereof

A technology of potassium-barium glass and lens, which is applied in the field of lens glass for car lights, and can solve problems such as spit acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The potassium-barium glass is produced as a lens product used in automobile lamps through the following preparation process, which specifically includes the following steps:

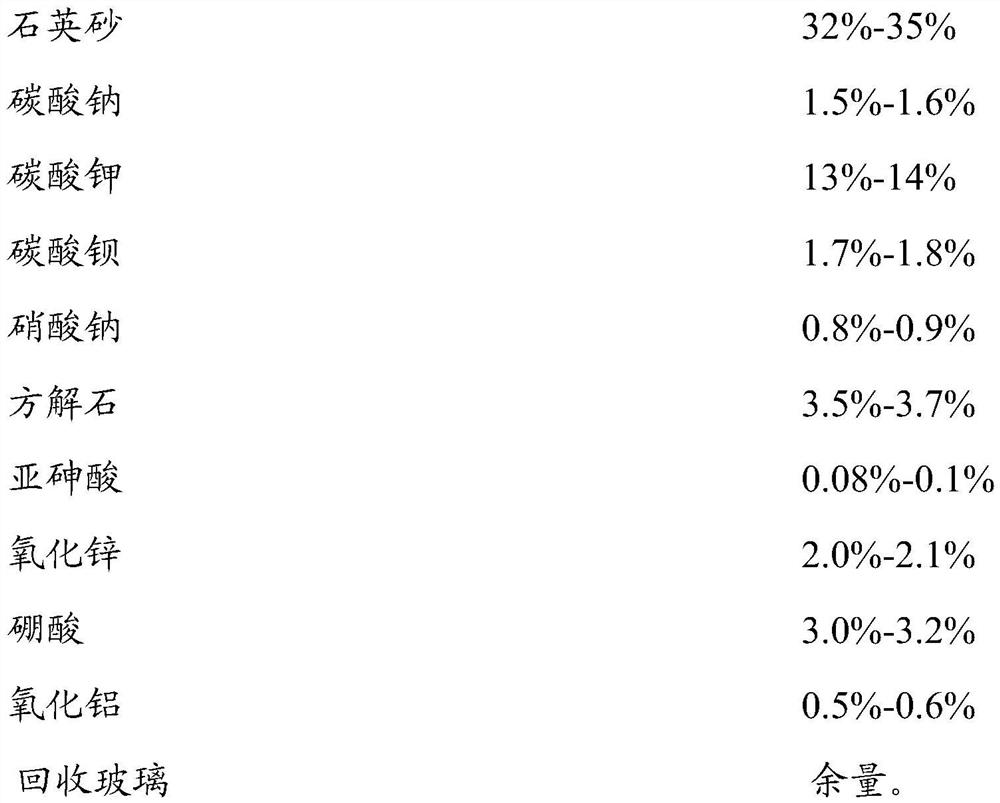

[0031] S1, batching: take the following components by weight, then put it into a mixing machine to make batches,

[0032]

[0033] S2. Melting: Mix the batch material with recycled glass, put a total of about 451kg into the melting furnace, keep it warm at about 1500°C for about 60 hours, and then pass through the roaring and ascending roads to obtain clear molten glass. The melting furnace is heated by electricity ;

[0034] S3, forming: the glass liquid is injected into the mould, and is molded by a dropping machine;

[0035] S4, annealing: the formed product is annealed in the following stages: the first stage of cooling annealing, the second stage of heat preservation, the third stage of cooling annealing and the fourth stage of natural cooling, and after being cooled to room temperature, ...

Embodiment 2

[0037] The potassium-barium glass is produced as a lens product used in automobile lamps through the following preparation process, which specifically includes the following steps:

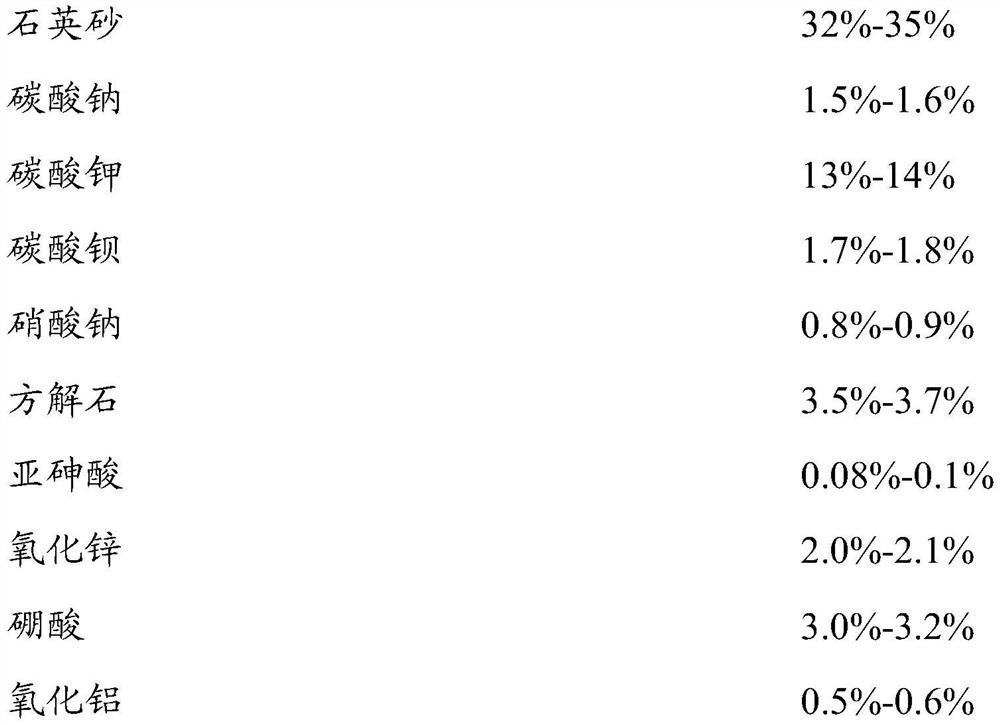

[0038] S1, batching: take the following components by weight, then put it into a mixing machine to make batches,

[0039]

[0040] S2. Melting: Mix the batch material with recycled glass, put a total of about 455kg into the melting furnace, keep it warm at about 1550°C for about 64 hours, and then pass through the roaring path and ascending path to obtain clarified molten glass. The melting furnace is heated by electric heating ;

[0041] S3, forming: the glass liquid is injected into the mould, and is molded by a dropping machine;

[0042] S4, annealing: the formed product is annealed in the following stages: the first stage of cooling annealing, the second stage of heat preservation, the third stage of cooling annealing and the fourth stage of natural cooling, and after being cooled to room ...

Embodiment 3

[0044] The potassium-barium glass is produced as a lens product used in automobile lamps through the following preparation process, which specifically includes the following steps:

[0045] S1, batching: take the following components by weight, then put it into a mixing machine to make batches,

[0046]

[0047]

[0048] S2. Melting: mix the batch material with recycled glass, put a total of about 453kg into the melting furnace, keep it warm at about 1450°C for about 56 hours, and then pass through the bellows and ascending roads to obtain clarified molten glass. The melting furnace is heated by electricity ;

[0049] S3, forming: the glass liquid is injected into the mould, and is molded by a dropping machine;

[0050] S4. Annealing: The formed product is annealed in the following stages: the first stage of cooling annealing, the second stage of heat preservation, the third stage of cooling annealing and the fourth stage of natural cooling. After cooling to room temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com