Preparation method of corrosion-resistant EVA foamed sheet

A foam sheet, corrosion resistance technology, applied in the field of EVA foam material preparation, can solve the problems of material deformation, reduced practicability, and reduced performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

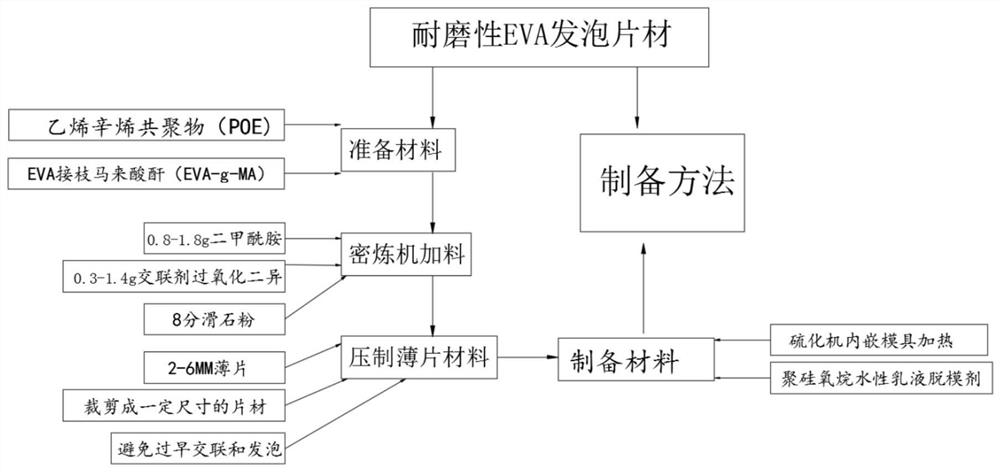

[0021] A method for preparing a corrosion-resistant EVA foam sheet, comprising the following steps,

[0022] S1. Preparation of equipment: firstly prepare the required materials fully, and then use the ethylene octene copolymer (POE) composite foam material and ethylene-vinyl acetate copolymer (EVA), EVA grafted with Malay The acid anhydride (EVA-g-MA) is distributed according to a certain proportion, and the parts by weight are fully mixed with 52 parts of EVA, 1-8 parts of EVA-g-MA and 2-6 parts of POE in the internal mixer , then add glycerin to process for five to eight minutes, then adjust the temperature of banburying to 100-115 degrees Celsius, and specify a certain number of minutes, usually about four minutes, and the speed is generally between 30-42rpm / min;

[0023] S2, internal mixer feeding: secondly, 0.8-1.8g weight portion of blowing agent azodicarbonamide, 0.3-1.4g weight portion of crosslinking agent diisoperoxide, and 8% talcum powder are added to the banburyi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com