A polyimide paper with controllable electrical properties and its preparation method

A technology of polyimide paper and polyimide, which is applied in papermaking, physical treatment of paper, textiles and papermaking, etc., can solve the problems of high production cost, uncontrollable electrical properties, low paper strength, etc., and simplify production steps. , the effect of improving research level and enriching variety forms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

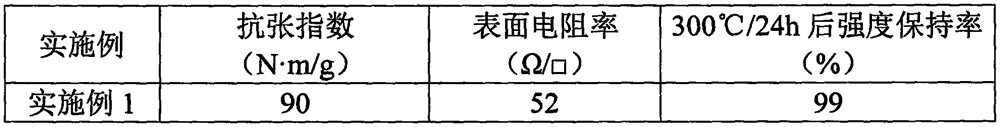

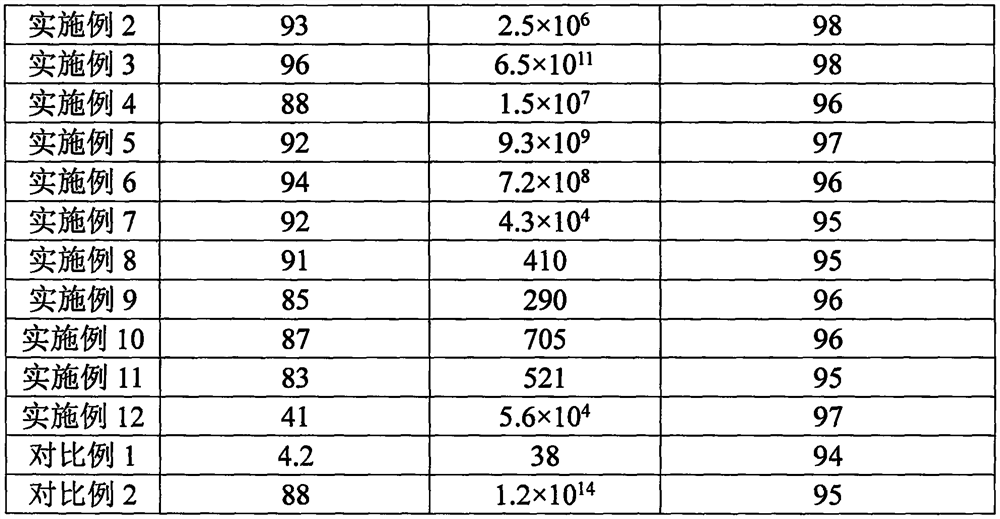

Examples

preparation example Construction

[0013] On the one hand, the present invention provides a kind of preparation method of polyimide paper with controllable electric performance, and the method comprises:

[0014] (1) Disperse polyimide chopped fibers, polyimide conductive fibers, polyamic acid precipitated fibers and polyimide precipitated fibers in an aqueous solution, or polyimide chopped fibers, polyimide Imide conductive fibers and polyimide precipitated fibers are dispersed in the aqueous solution, and then the polyamic acid solution is mixed with polyimide chopped fibers, polyimide conductive fibers and polyimide precipitated under stirring conditions. Precipitate in the aqueous solution of the fiber to make polyamic acid form polyamic acid precipitated fiber, and make polyimide-containing chopped fiber, polyimide conductive fiber, polyamic acid precipitated fiber and polyimide precipitated fiber Aqueous solution of fiber;

[0015] (2) The product obtained in step (1) is subjected to papermaking, rolling...

preparation example 1

[0049] This preparation example is used to prepare polyamic acid fibrids and polyimide fibrids.

[0050] (1) Dissolve 3,4-diaminodiphenyl ether in a mixed solvent of N,N-dimethylacetamide and xylene with a volume ratio of 6:1, and then add acid anhydride monomers (acid anhydride monomers The composition is: 2,3,3',4'-biphenyl tetra-acid dianhydride, 3,3',4,4'-benzophenone tetra-acid dianhydride and 3,3',4,4'-biphenyl tetra-acid dianhydride Phenyl ether tetra-acid dianhydride, the weight ratio is 1:1:5), the molar ratio of 3,4-diaminodiphenyl ether and acid anhydride monomer is controlled to be 1:0.95, and the solid content in every liter of mixed solvent is 200g , stirring and reacting at 10°C for 2h to generate polyamic acid product;

[0051] (2) Add the above-mentioned mixed solvent to the polyamic acid product obtained in step (1) until the content of polyamic acid is 5% by weight, and the solution viscosity is 200cp, and then inject it at 30°C and 600r / min stirring speed ...

preparation example 2

[0055] This preparation example is used to prepare polyamic acid fibrids and polyimide fibrids.

[0056] (1) Hexafluorodiamine is dissolved in N, N-dimethylacetamide and xylene in a mixed solvent with a volume ratio of 7:1, and then an acid anhydride monomer is added (the composition of the acid anhydride monomer is: 2 , 3,3',4'-biphenyl tetraacid dianhydride, 3,3',4,4'-benzophenone tetraacid dianhydride and 3,3',4,4'-diphenyl ether tetraacid di Anhydride, the weight ratio is 1:2:2), the molar ratio of hexafluorodiamine and acid anhydride monomer is controlled to be 1:1, and the solid content in each liter of mixed solvent is 240g, and the reaction is stirred at 25°C for 1h to form poly Amic acid products;

[0057] (2) Add the above-mentioned mixed solvent to the polyamic acid product obtained in step (1) until the content of polyamic acid is 7% by weight, and the solution viscosity is 250cp, and then inject it at 50°C and 800r / min stirring speed In deionized water, continue...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com