Carbon nanotube field effect transistor sensor and manufacturing method thereof

A field-effect transistor and carbon nanotube technology, which is applied in the field of carbon nanotube field-effect transistor sensor and its preparation, can solve the problem of low sensitivity, difficulty in directly modifying the surface of carbon nanotube layer, and good products of carbon nanotube field-effect transistor sensor Low efficiency and other problems, to achieve the effect of improving sensitivity and improving sensing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

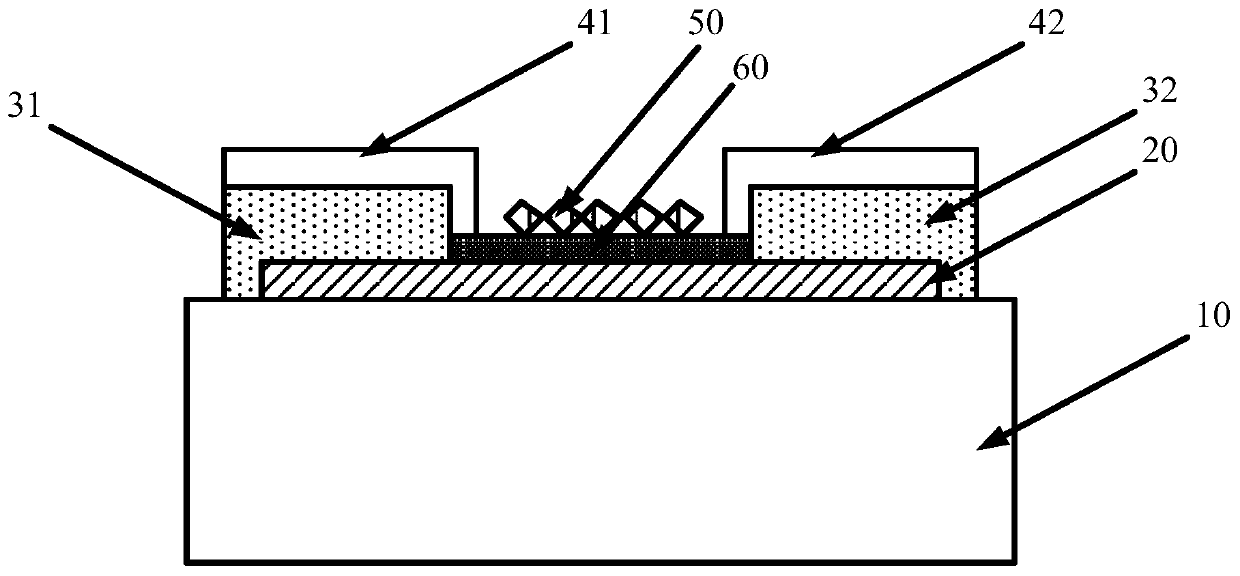

[0050] As mentioned in the background art, carbon nanotubes have a size of 1-2 nm and are easily regulated by external molecules, so they are very suitable for use as biosensors. However, in the prior art, it is very difficult to directly modify the surface of the sensitive layer of the carbon nanotube field effect transistor sensor on the carbon nanotube layer, because the carbon nanotubes in the carbon nanotube layer are formed by carbon atoms hybridized with SP2 The tubular structure of the substance has only in-plane delocalized large π bonds on the surface, and the surface lacks out-of-plane dangling bonds, and the sensitive layer cannot be stably formed on the carbon nanotube layer in a covalently modified manner through dangling bonds.

[0051] Some studies have produced defects by destroying carbon nanotubes to generate dangling bonds, so that the sensitive layer can be covalently modified through the dangling bonds, or the sensitive layer can be realized by ππ bond sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com