Patents

Literature

49results about How to "Solve the low yield rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

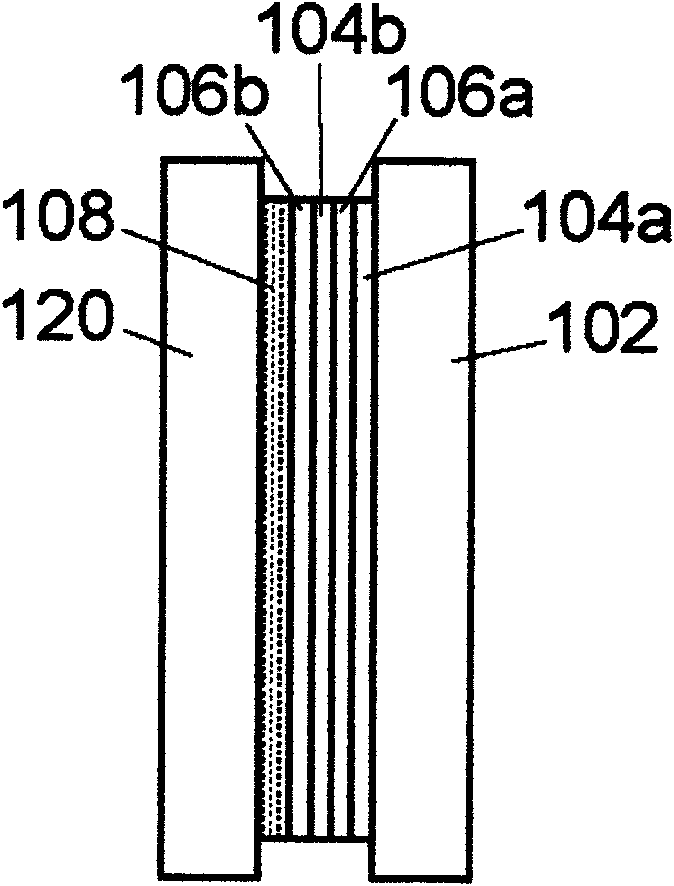

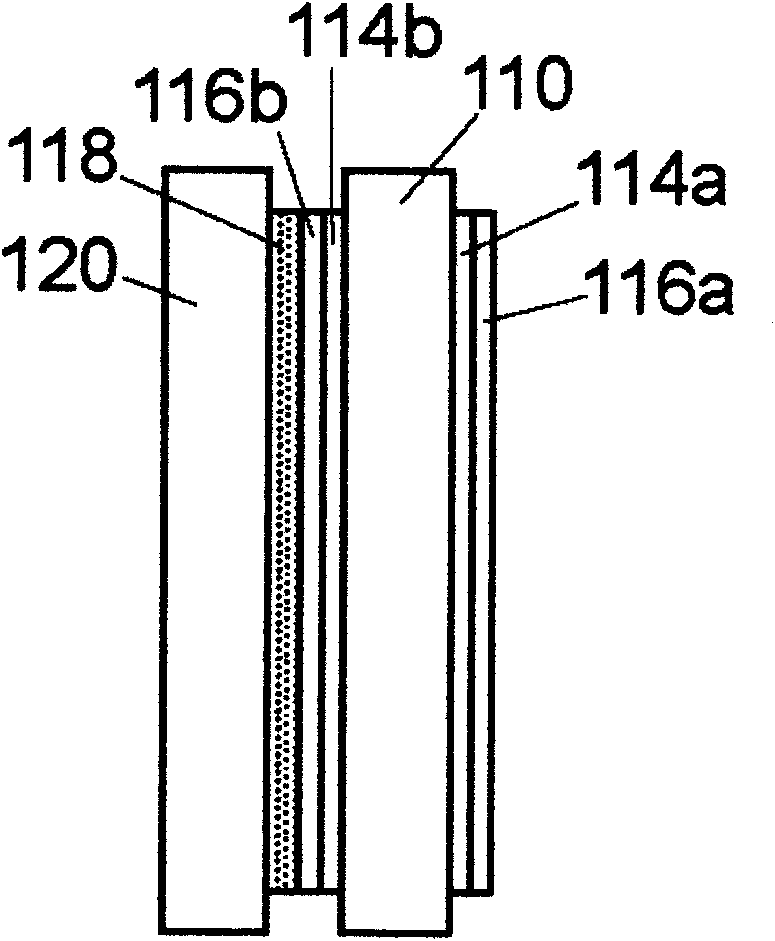

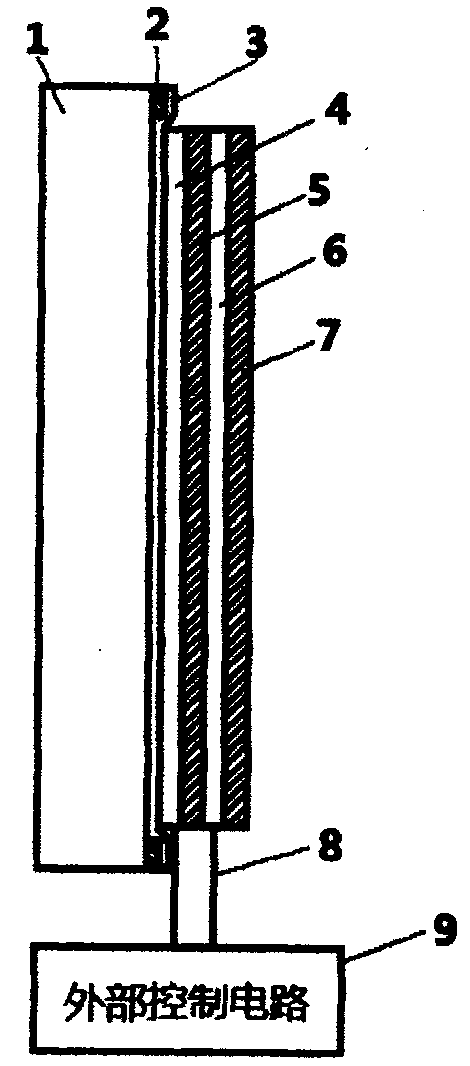

Integrated projection-type capacitive touch screen and manufacturing method thereof

InactiveCN101853115AReduce thicknessGuaranteed transmittanceInput/output processes for data processingDielectricComposite film

The invention relates to an integrated projection-type capacitive touch screen and a manufacturing method thereof. The integrated projection-type capacitive touch screen only adopts a substrate, and a color coating is arranged in the non-visible range of the substrate; a backing insulating film is arranged on the whole surface of the substrate with the color coating, and a first electrode pattern is arranged on the backing insulating film; a dielectric insulating film is arranged on the first electrode pattern, and a second electrode pattern is arranged on electrolyte insulating film; the coverage of the electrolyte insulating film does not include joint terminals of the first electrode pattern, and a protective insulating film is arranged on the second electrode pattern; and the coverage of the protective insulating film does not include joint terminals on the edges of the first electrode pattern and the second electrode pattern, and the upper ends of the joint terminals are connected with an external control circuit through collecting lines. The single substrate with the color coating adopts a multi-layer composite film structure of the backing insulating film, an ITO film, the dielectric insulating film, the ITO film and the protective insulating film, can substantially reduce the thickness of the touch screen, and improves lightness thinness and yield.

Owner:上海优熠电子科技有限公司

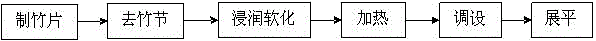

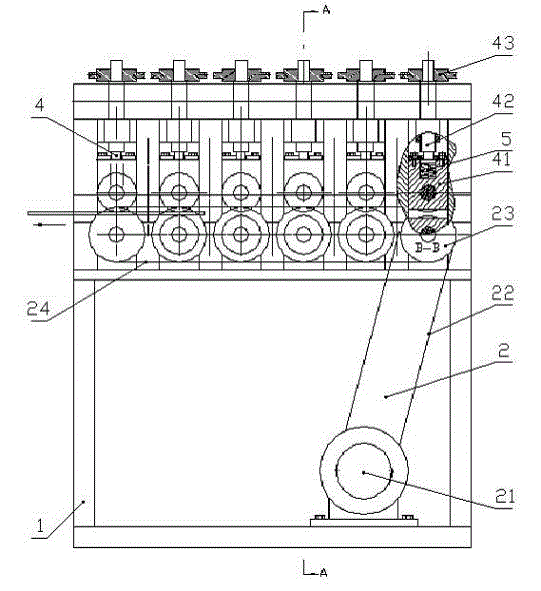

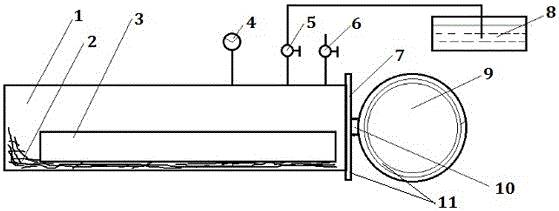

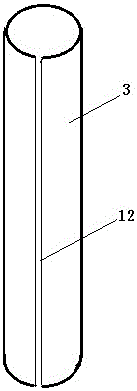

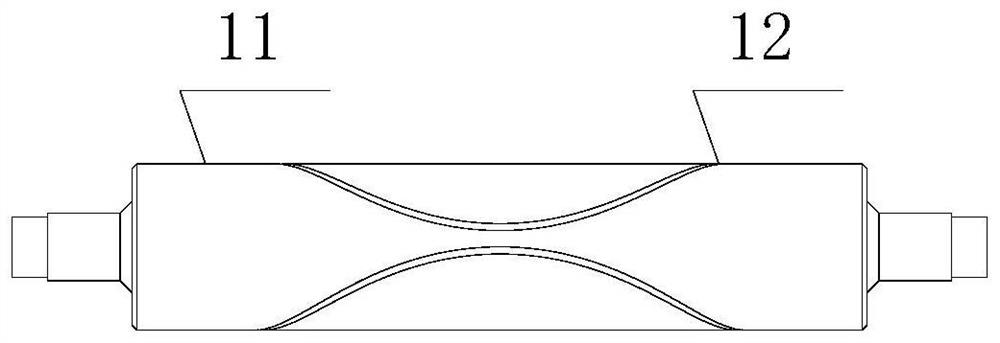

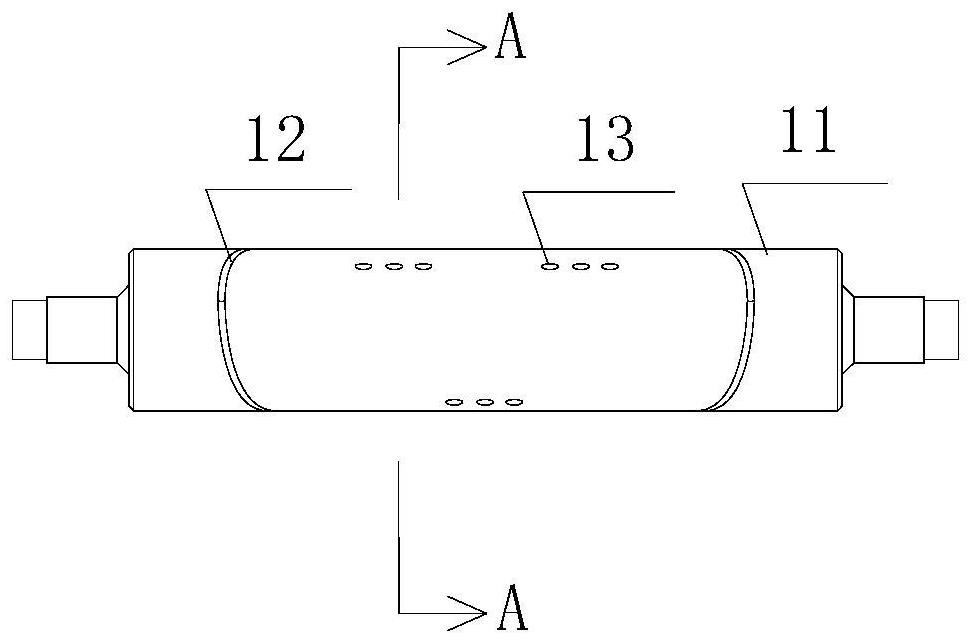

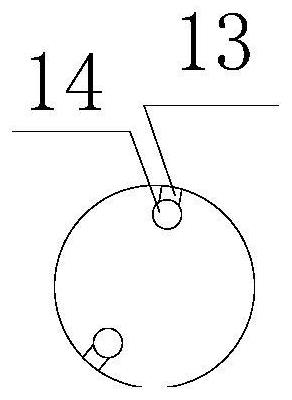

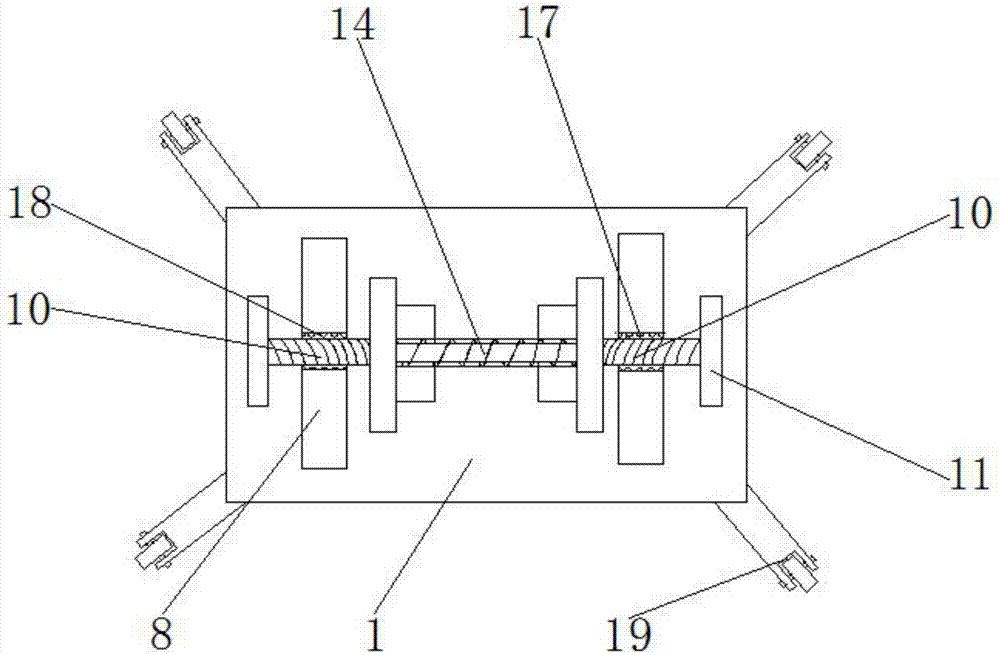

Mao bamboo continuous-flattening processing method and equipment

InactiveCN102873732AReduce process complexitySolve the low yield rateWood compressionWood treatment detailsEngineeringProcess complexity

The invention relates to a Mao bamboo continuous-flattening processing method which comprises the following steps of: bamboo chip making: cutting fresh Mao bamboo and breaking into Mao bamboo chips; bamboo joint removal: removing the inner and outer joints of the Mao bamboo chips and arranging shallow slash grooves on the inner walls of the Mao bamboo chips; infiltration and softening: bundling the Mao bamboo chips and putting into a pond, injecting water and adding a bamboo fiber softener into the water; heating: filling steam into the bamboo chip pond and taking out after the bamboo fibers are fully softened; adjustment: adjusting the transverse feeding speed and the gap between the upper and lower rolls of each group; and flattening: sending the Mao bamboo chips into Mao bamboo continuous-flattening equipment for flattening. The invention also relates to Mao bamboo continuous-flattening processing equipment which comprises a motor and upper and lower roll groups driven by the motor. According to the method and the equipment provided by the invention, the Mao bamboo chips pre-softened at earlier stage can be efficiently flattened, so that the process complexity in the existing bamboo processing is solved, the problem of low outturn percentage in the existing bamboo processing is solved, the technological content and the product added value of the bamboo product industry can be comprehensively enhanced and vast potential for future development is provided.

Owner:FUJIAN HENGSHUN METAL MACHINERY

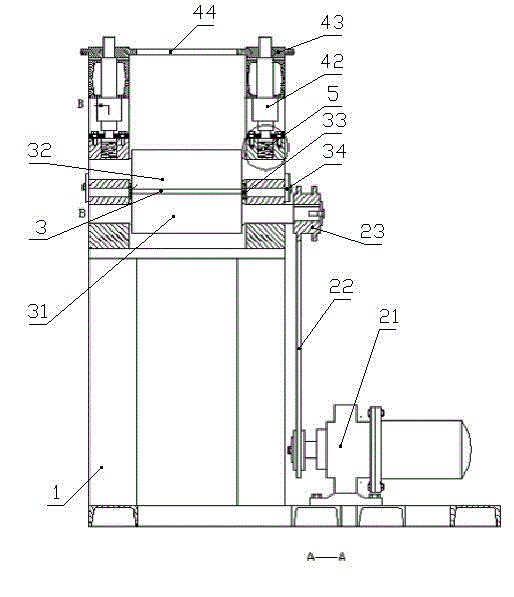

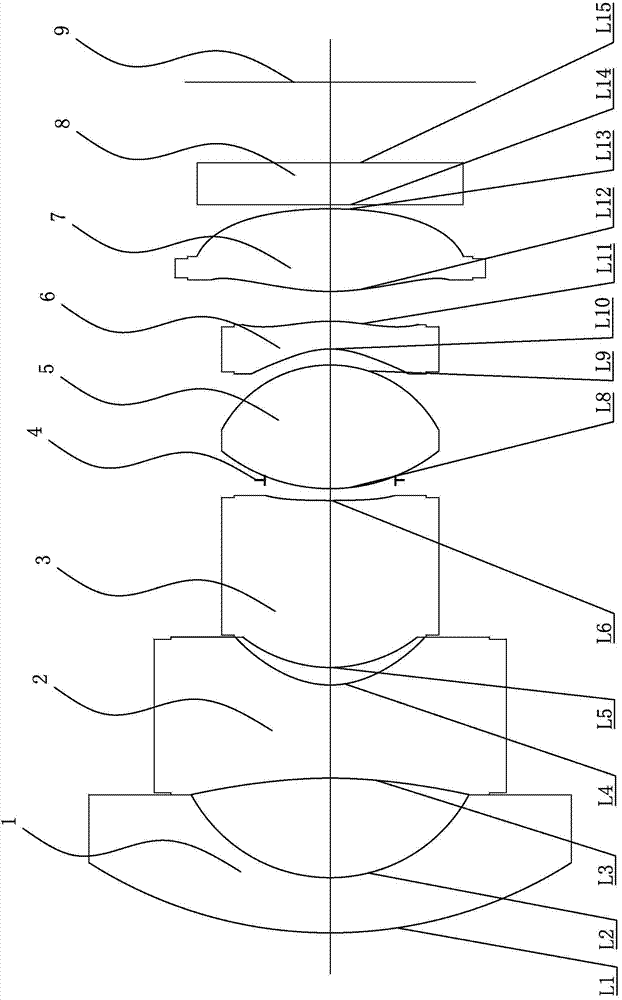

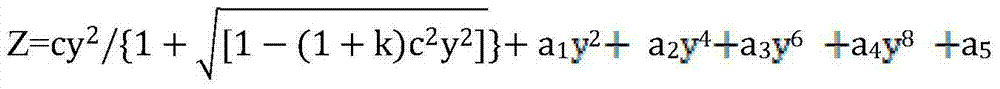

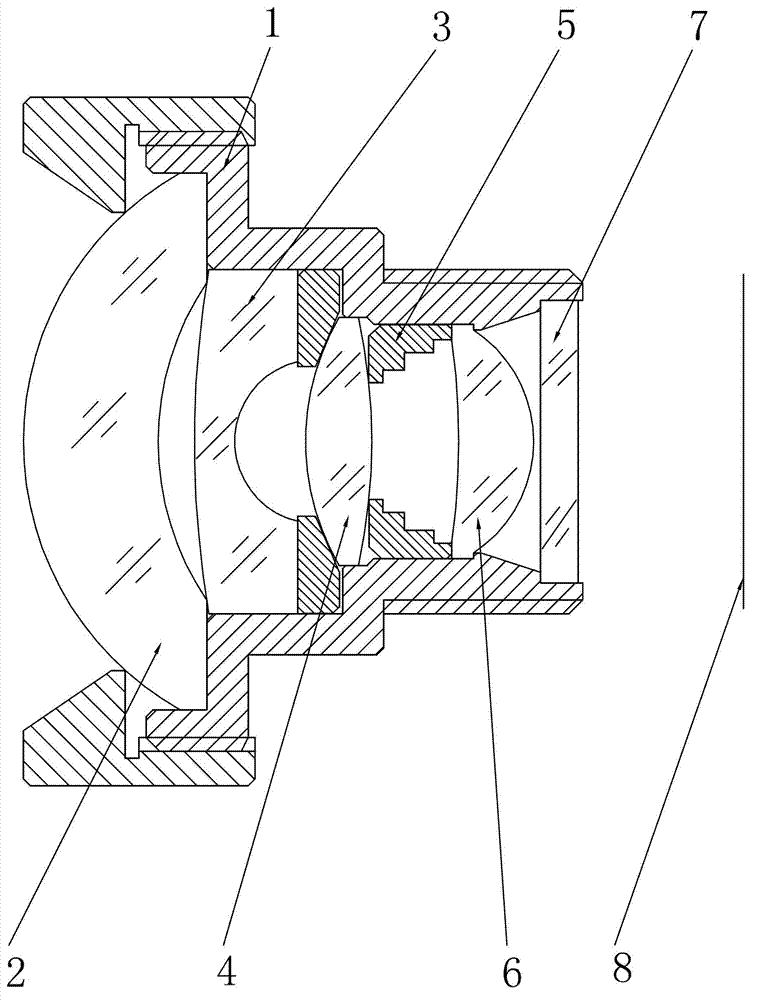

Infrared confocal optical system with low temperature excursion, low cost and high pixel

The invention discloses an infrared confocal optical system with low temperature excursion, low cost and high pixel. The infrared confocal optical system sequentially comprises a first lens (1), a second lens (2), a third lens (3), a diaphragm (4), a fourth lens (5), a fifth lens (6), a sixth lens (7), an optical filter (8) and an image surface (9) from an object side, wherein the first lens (1) is in a falcate spherical lens, the second lens (2) is a double concave aspherical lens, and the third lens (3) is a falcate aspherical lens; the fourth lens (5) is a double convex spherical lens, the fifth lens (6) is a falcate aspherical lens, and the sixth lens (7) is a double convex aspherical lens.

Owner:UNION OPTECH

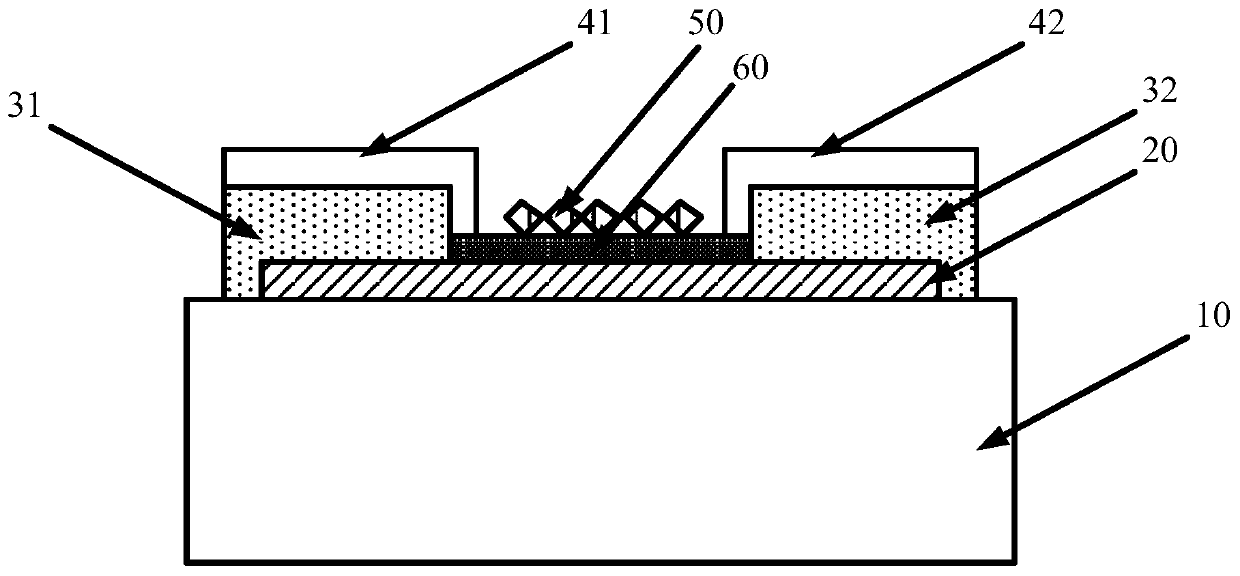

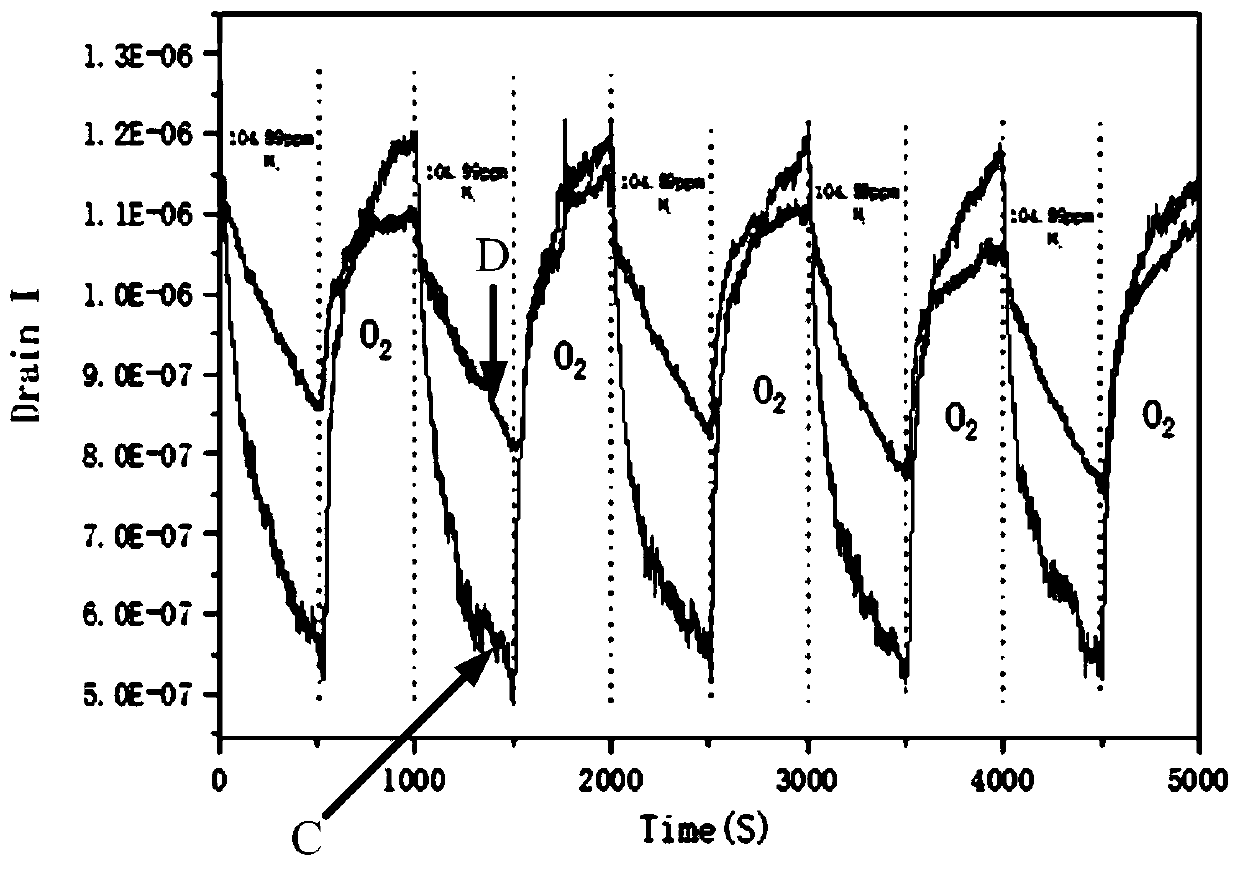

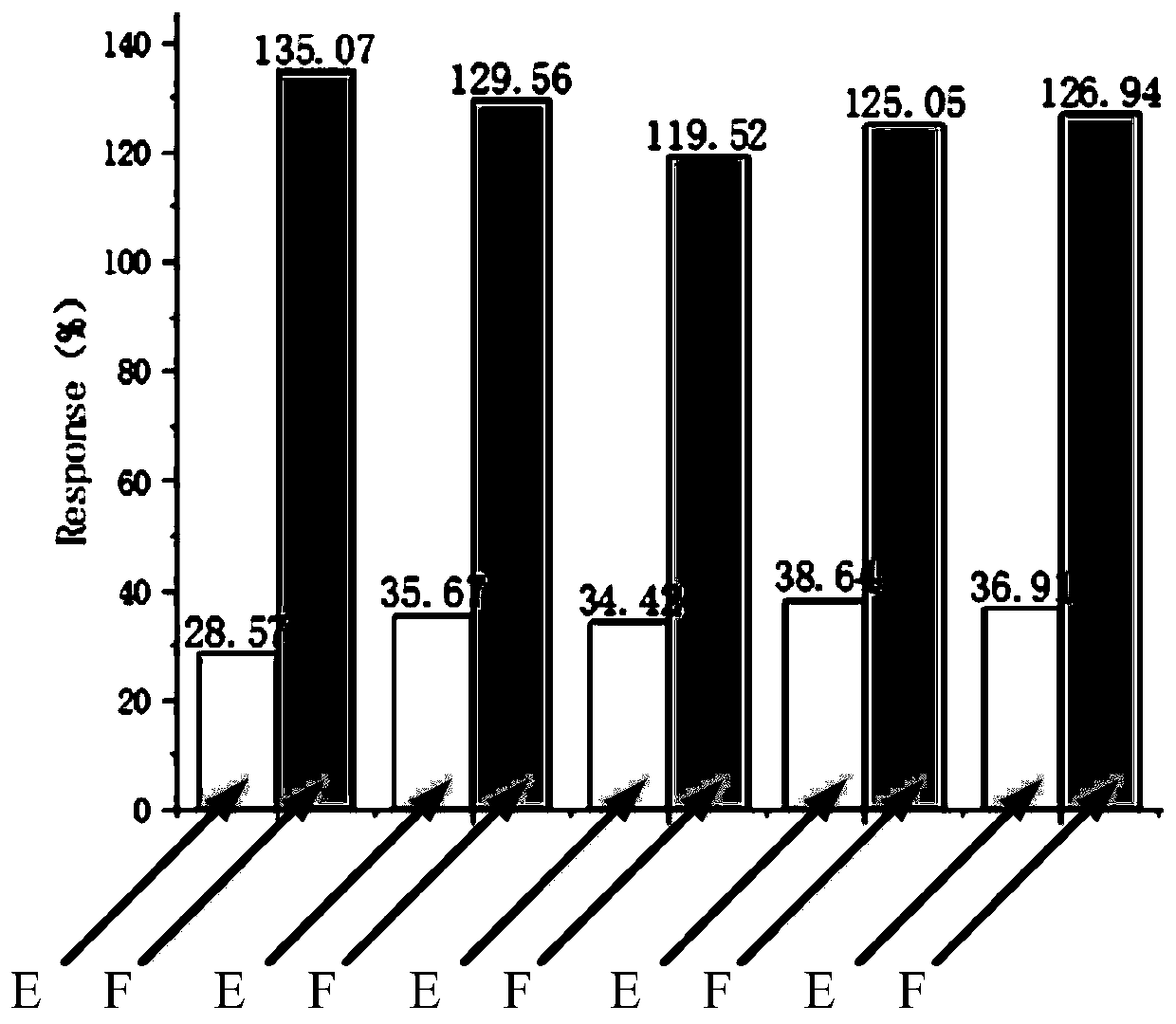

Carbon nanotube field effect transistor sensor and manufacturing method thereof

InactiveCN110596222AImprove sensing efficiencyHigh sensitivityMaterial analysis by electric/magnetic meansSemiconductor/solid-state device manufacturingCarbon nanotubeCovalent modification

The invention discloses a carbon nanotube field effect transistor sensor and a manufacturing method thereof. The carbon nanotube field effect transistor sensor is characterized in that one side, deviating from a substrate, of a carbon nanotube layer is provided with an ultrathin dielectric layer capable of uniformly covering the carbon nanotube layer. When a sensitive layer adsorbs a target substance in the working process, the electrochemical performance generated by the carbon nanotube layer as a channel can be effectively regulated and controlled, so that the effect of the sensitive layer on the channel is more comprehensive and average; the sensing efficiency of the carbon nanotube field effect transistor sensor is improved effectively; and the sensitivity of the carbon nanotube fieldeffect transistor sensor is enhanced. In the presence of the dielectric layer, a dangling bond which can be connected with a covalent bond is provided for the modification of the sensitive layer, so that the sensitive layer can be arranged on the dielectric layer in a covalent modification way; the modification method for the sensitive layer is extended; and the problem of low yield of the conventional carbon nanotube field effect transistor sensor is solved.

Owner:PEKING UNIV +2

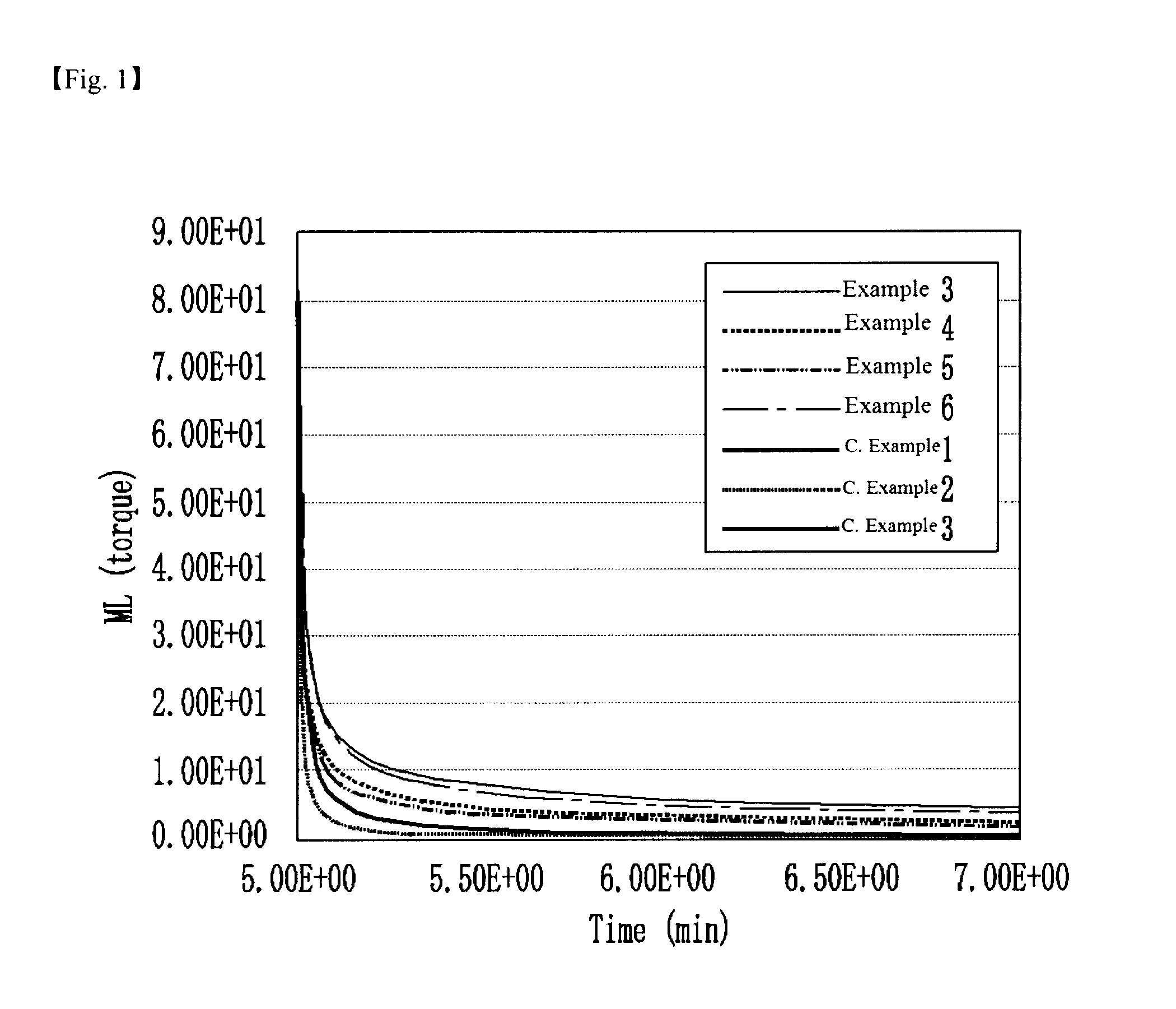

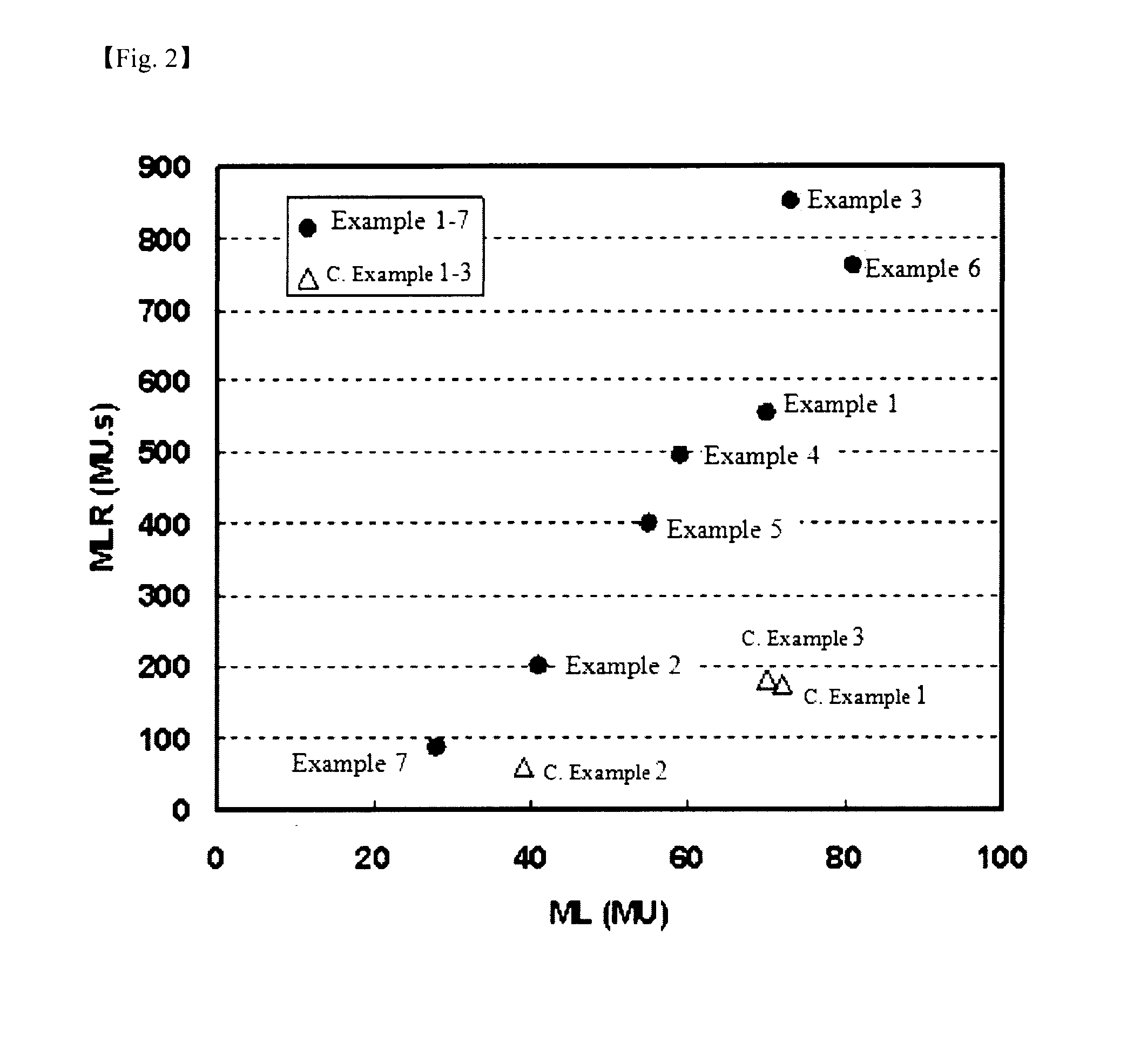

Elastic terpolymer including diene group and preparation method thereof

The present invention relates to an elastic terpolymer which can satisfy excellent processability and elasticity (flexibility) at the same time, and a preparation method thereof. The elastic terpolymer is a copolymer of 40 to 70 weight % of ethylene, 15 to 55 weight % of a C3-C20 alpha-olefin, and 0.5 to 20 weight % of a diene obtained in the presence of a group 4 transition metal catalyst, of which i) the weight average molecular weight measured by GPC is 100,000 to 500,000, and ii) the Mooney viscosity (ML) and the Mooney relaxation area (MLR) measured by a Mooney viscometer (1+4+{circle around (a)}125° C.) can satisfy a specific relation.

Owner:LG CHEM LTD

Vehicle-mounted optical lens for monitoring

The invention relates to a vehicle-mounted optical lens for monitoring. The vehicle-mounted optical lens for monitoring comprises a lens barrel, wherein a first lens, a second lens, a third lens, a diaphragm and a fourth lens which are sequentially arranged in the lens barrel from object space to image space. The first lens is a falcate spherical lens, the second lens is falcate aspheric lens, a first surface of the second lens facing the object space is a hyperbolic curve aspheric surface, and a second surface of the second lens facing the image space is an oval aspheric surface. The third lens is a biconvex spherical lens. The fourth lens is a falcate aspheric lens, and double surfaces of the fourth lens are hyperbolic curve aspheric surfaces. The vehicle-mounted optical lens for monitoring overcomes the shortcomings of the prior art, is high in pixel, ultra-wide in field, small in distortion and fog-transmitting, can be used for monitoring and can be used all day.

Owner:UNION OPTECH

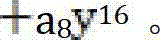

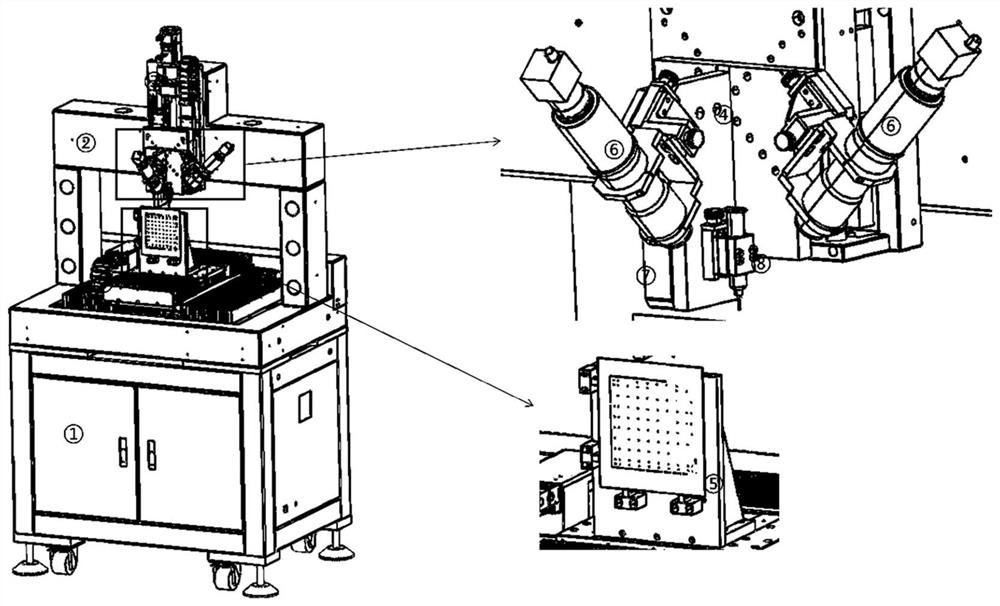

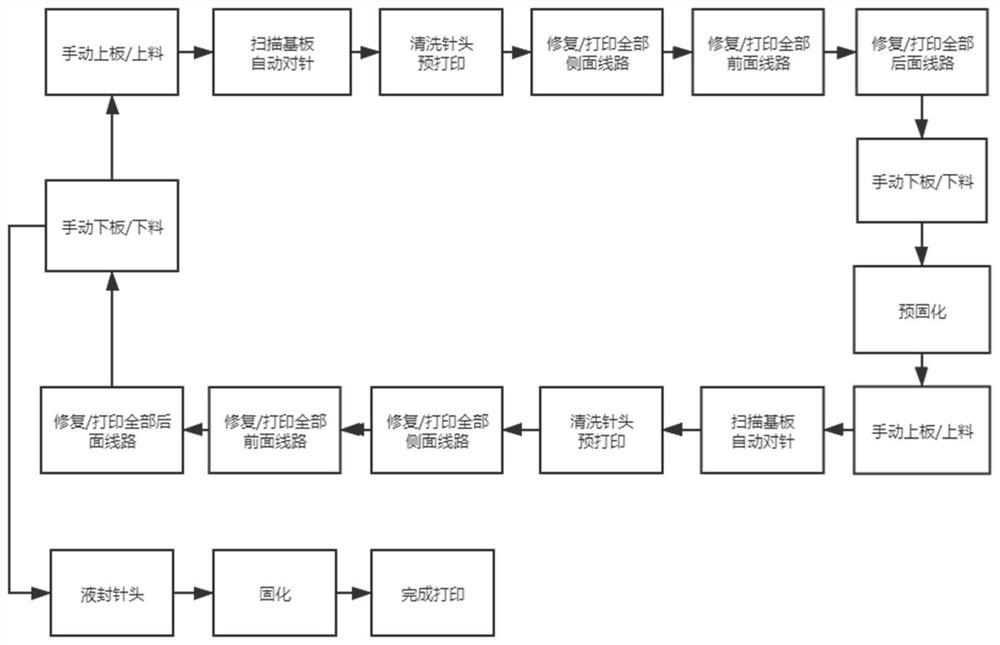

Glass substrate circuit printing method and equipment

PendingCN113696638ASolve complexitySolve the low yield rateTypewritersOther printing apparatusEngineeringFluid control

The invention relates to glass substrate circuit printing method and equipment. The equipment comprises an ultrahigh-precision motion control system which is connected with a computer and is used for controlling the movement speed and the printing receiving distance of a printing glass substrate circuit and a printing needle head; a sucker device is which connected with the ultrahigh-precision motion control system and comprises suckers for fixing a glass substrate; a height measurement and automatic following system which is connected with the computer and comprises a sensor and a sensor controller, wherein the sensor is used for measuring space coordinates of the glass substrate and the printing needle head; and a high-precision fluid control system which comprises a printing needle head and a fluid control system, wherein the fluid control system is used for providing preset air pressure for the printing needle head, the inner diameter of the printing needle head is matched with the preset printing line width, and the air pressure, the needle head movement speed and the printing receiving distance are matched with the printing needle head. According to the method and equipment, the printing yield and the production efficiency of the glass substrate circuit are improved.

Owner:西湖未来智造(杭州)科技发展有限公司

Processing method of round bamboo high-temperature hardening, softening and flattening

ActiveCN106738154AReduce process complexitySolve the low yield rateWood treatment detailsCane mechanical workingProcess complexityMaterials processing

The invention relates to a processing method of round bamboo high-temperature hardening, softening and flattening. The method comprises the steps that moso bamboos are selected and cut into standard round bamboo sections, outer and inner knots are removed, and the round bamboo sections are laterally sawn; the laterally-sawn round bamboo sections are soaked with hot water and fed into a round bamboo high-temperature hardening and softening device to be baked and softened, after preset softening requirements are met, a valve of a water storage groove is opened, water in the water storage groove is sprayed to the high-temperature baked round bamboo sections, and hardening and softening treatment is completed; and finally, the hardened and softened round bamboo sections are taken out to be fed into a bamboo flattening machine to be flattened, the flattened bamboo boards are fed into a two-side surface planer to be processed, and standard displayed bamboo board finished products are manufactured. By means of the method, the process complexity of existing bamboo material processing can be lowered, the problem that the outturn percentage is low in bamboo material processing is low is solved, the technological content and product added value of bamboo product industry can be comprehensively improved, and the development prospect is wide.

Owner:FUJIAN AGRI & FORESTRY UNIV

Surface treatment method of zinc-alloy high-hardness abrasion-resistant imitating electroplating hexavalent chromium

ActiveCN104099616AHigh surface hardnessSolve the low yield rateVacuum evaporation coatingSputtering coatingCeramic compositeDiamond-like carbon

The invention relates to a surface treatment method of zinc-alloy high-hardness abrasion-resistant imitating electroplating hexavalent chromium. The method is characterized by comprising the steps as follows: 1) surface treatment is performed on a to-be-treated zinc alloy workpiece; 2) the workpiece is placed into a hydrofluoric acid solution to be etched and activated; 3) the activated workpiece is washed clean with pure water and then placed into a silane oxide tank solution for silane conversion coating treatment, and the workpiece is washed with water after treatment; 4) the workpiece is placed into an electrophoresis tank for electrophoresis, and an electrophoresis coating is formed on the surface of the workpiece; 5) cleaning is performed; 6) pre-drying is performed; 7) ultraviolet curing is performed; 8) the workpiece is hung in a PVD (physical vapor deposition) furnace, and a layer of metal and ceramic composite film is formed; 9) finally, PVD is performed on the surface of the workpiece again, and a layer of transparent DLC (diamond like carbon) film is deposited. By the aid of the method, the problem of the low good product yield of an electroplated zinc alloy due to die-casting sand holes and nests and the like is solved, the quality is stable, and the good product yield is high; the method is environment-friendly, simple in process and low in energy consumption.

Owner:NINGBO RUNNER INDAL CORP

Optical lens

The invention relates to an optical lens, aims to overcome the defects in the prior art, and provides a high-image quality micro aspheric optical lens which is high in pixel and small in size, can be used for a digital camera and a mobile phone, and has a mixed lens structure. The lens comprises a lens cone, a bearing and a diaphragm; a first lens, a second lens, a third lens and a fourth lens are sequentially arranged in the lens cone from inside to outside; the first lens is a biconvex aspheric lens; the second lens has a section which is a falcate spherical surface; the third lens has a section which is a hyperbolic aspheric surface; and the fourth lens has a section which is a hyperbolic aspheric surface. The optical lens is mainly applied to camera cell phones.

Owner:UNION OPTECH

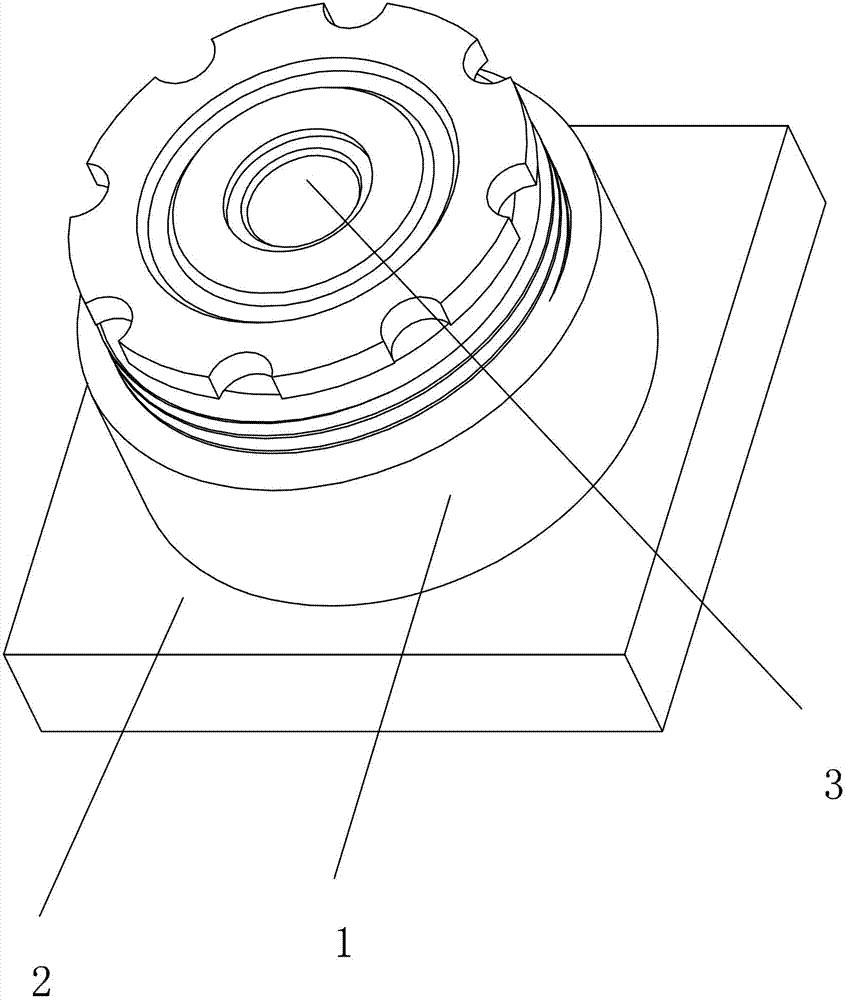

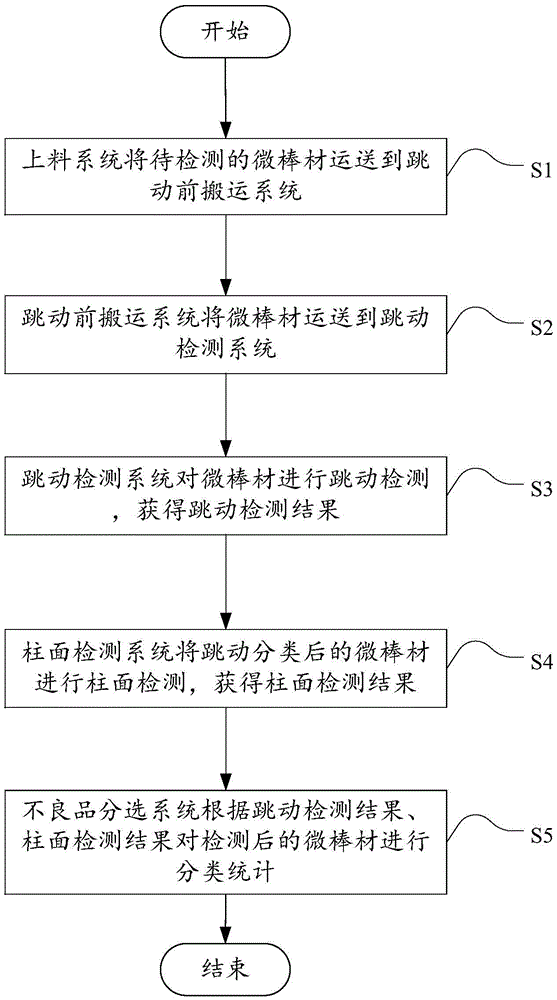

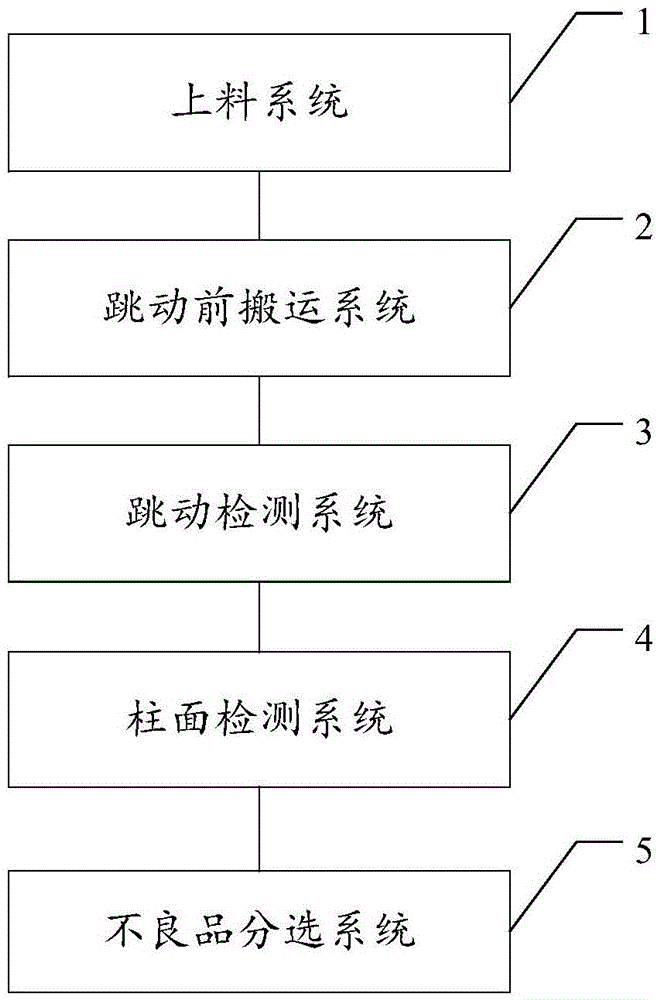

Detection method and system for micro bar materials

ActiveCN105618387ASolve the problem of not being able to detect surface defects on micro-barsHigh precisionUsing optical meansSortingTest sampleEngineering

The embodiment of the invention discloses a detection method and system for micro bar materials. The method comprises the steps that a feeding system conveys the micro bar materials to be detected to a before-jumping carrying system; the before-jumping carrying system conveys the micro bar materials to a jumping detection system; the jumping detection system carries out jumping detection on the micro bar materials, and a jumping detection result is obtained; a cylindrical detection system carries out cylindrical detection on the micro bar materials obtained after jumping classifying, and a cylindrical detection result is obtained; and a defective-product sorting system carries out classified statistic on the detected micro bar materials according to the jumping detection result and the cylindrical detection result. According to the method and system, precision and repeat reliability of the detection result can be improved; in addition, the detection efficiency can be improved, different kinds of failed test samples can be subject to classified statistic, the problems that in the prior art, when manual detection is adopted, the false drop rate is high, the yield is low, and detection reliability is low are solved, and the problem that in the prior art, surface defective detection cannot be carried out on the micro bar materials can also be solved.

Owner:GUANGDONG INST OF INTELLIGENT MFG +1

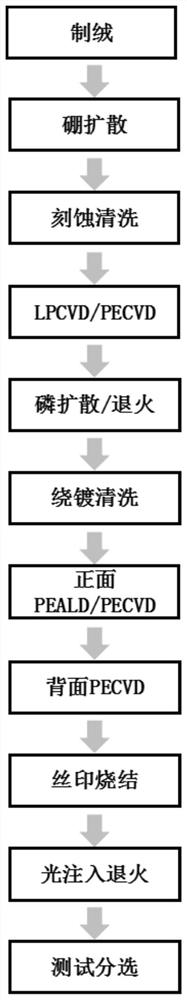

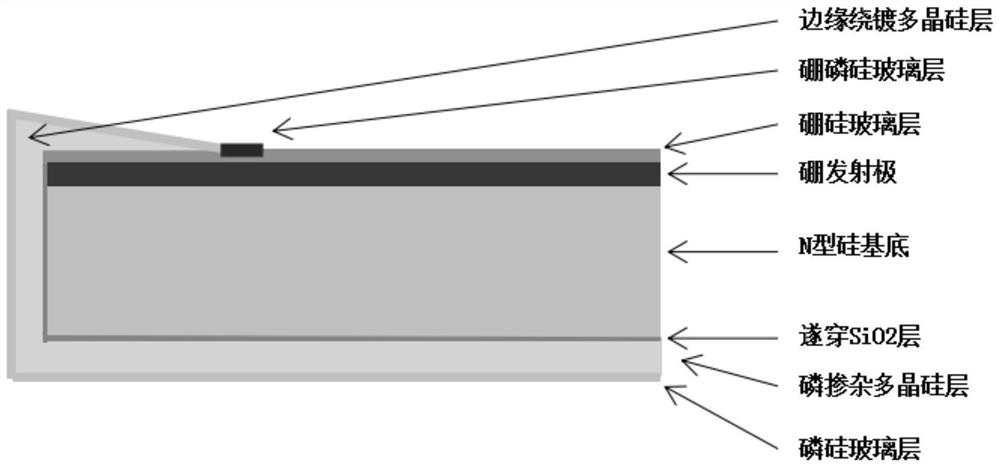

Cleaning process of winding plating polycrystalline silicon

PendingCN114122195AReduce manufacturing costImprove use valueFinal product manufactureSemiconductor/solid-state device manufacturingPhysicsSilicon chip

The invention discloses a cleaning process of wound-plated polycrystalline silicon, which comprises the following steps of: obtaining a silicon wafer with wound-plated polycrystalline silicon, cleaning the front surface and the edge of the silicon wafer by adopting a hydrofluoric acid solution, and controlling the flow of a water film to be 5mL / wafer-40mL / wafer, so that the thinning amount of a front surface BSG layer is 20nm-60nm, and the retaining thickness of the BSG layer is more than 40nm; and removing the polycrystalline silicon plated on the front surface and the edge of the silicon wafer under the protection of the BSG layer and the PSG layer on the front surface and the back surface of the silicon wafer, and removing the BSG layer on the front surface and the PSG layer on the back surface of the silicon wafer. According to the cleaning process, the problems of low battery conversion efficiency and low yield caused by polycrystalline silicon winding plating can be effectively solved, the capacity of an LPCVD machine can be released, the use value is high, the application prospect is good, and the cleaning process has important significance in reducing the production cost of the TOPCon battery, improving the capacity of the TOPCon battery and improving the conversion efficiency and the yield of the TOPCon battery.

Owner:湖南红太阳新能源科技有限公司

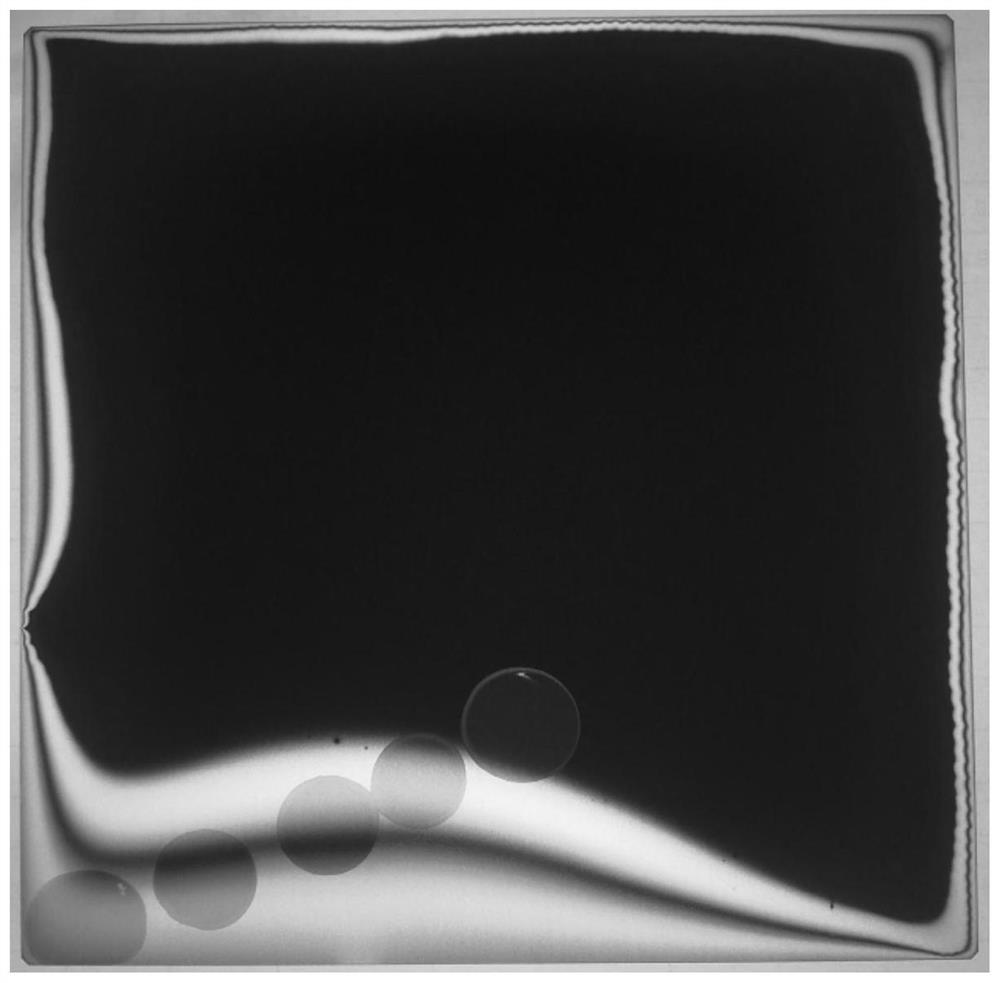

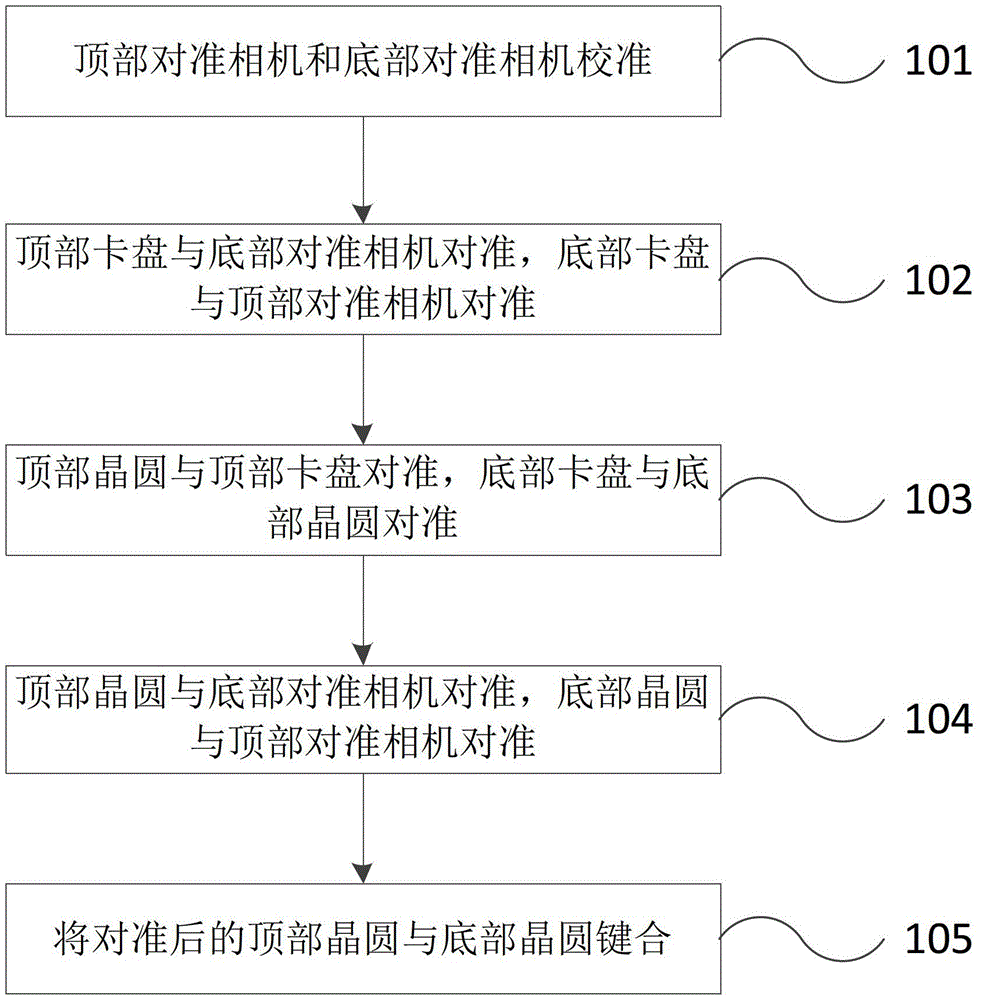

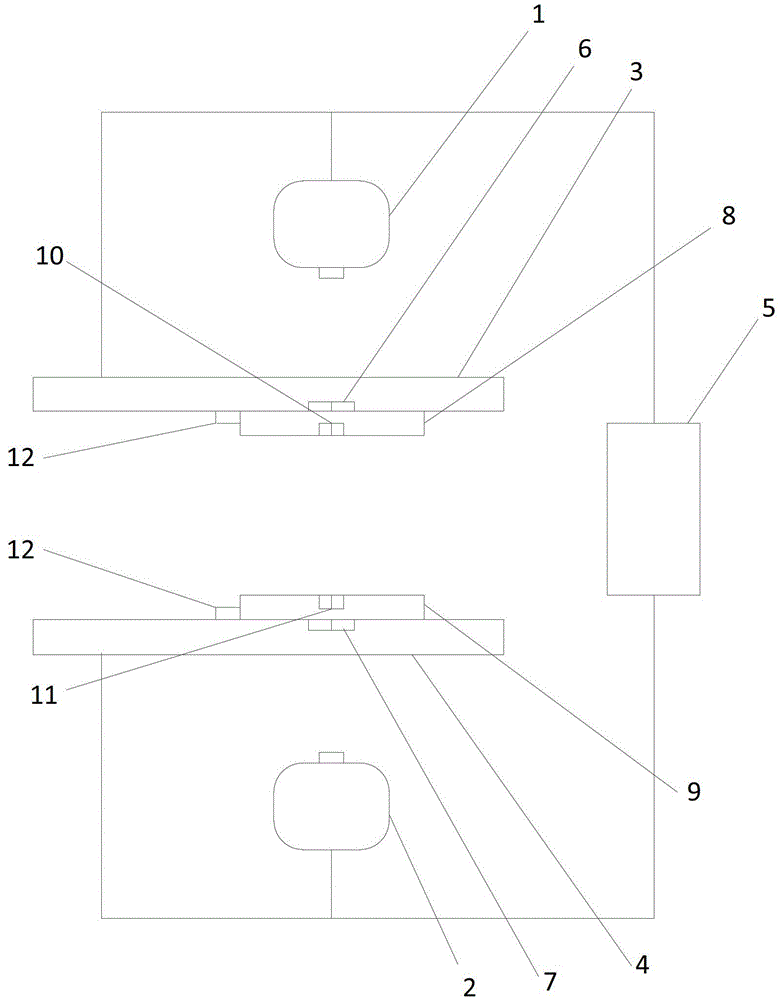

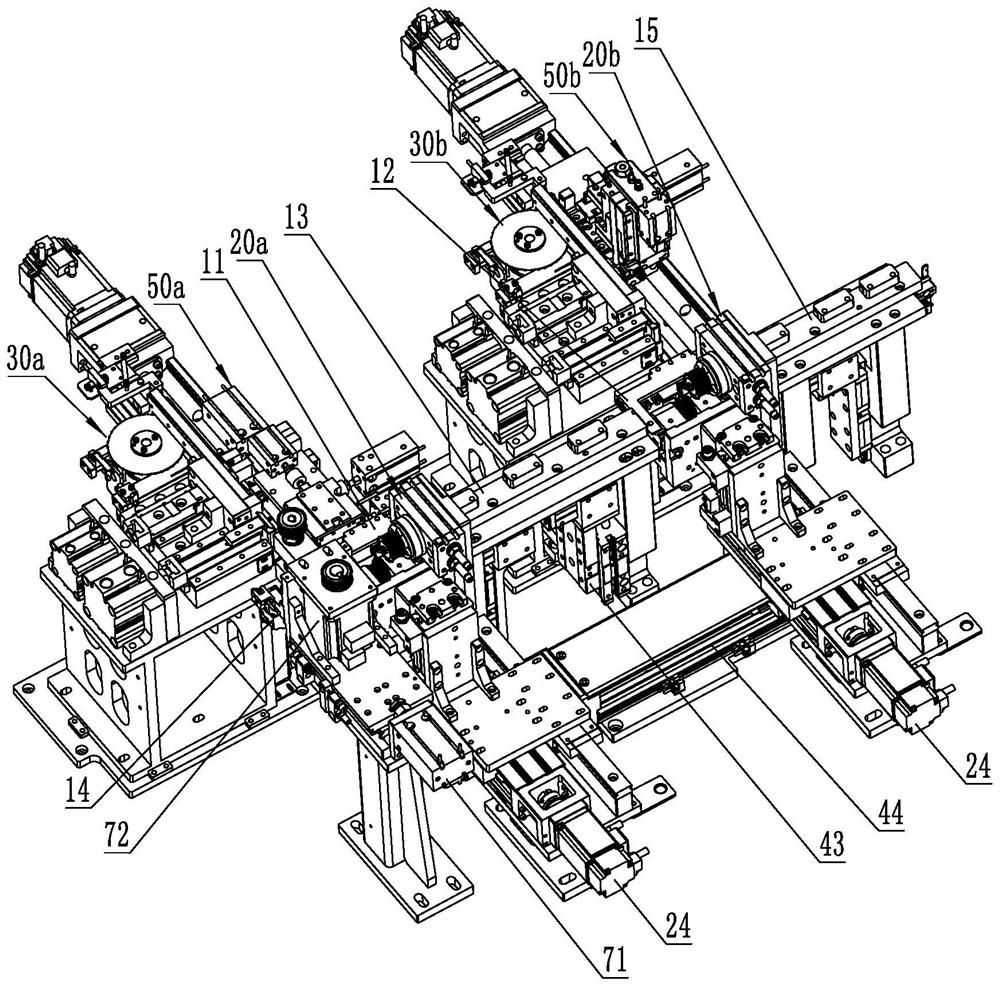

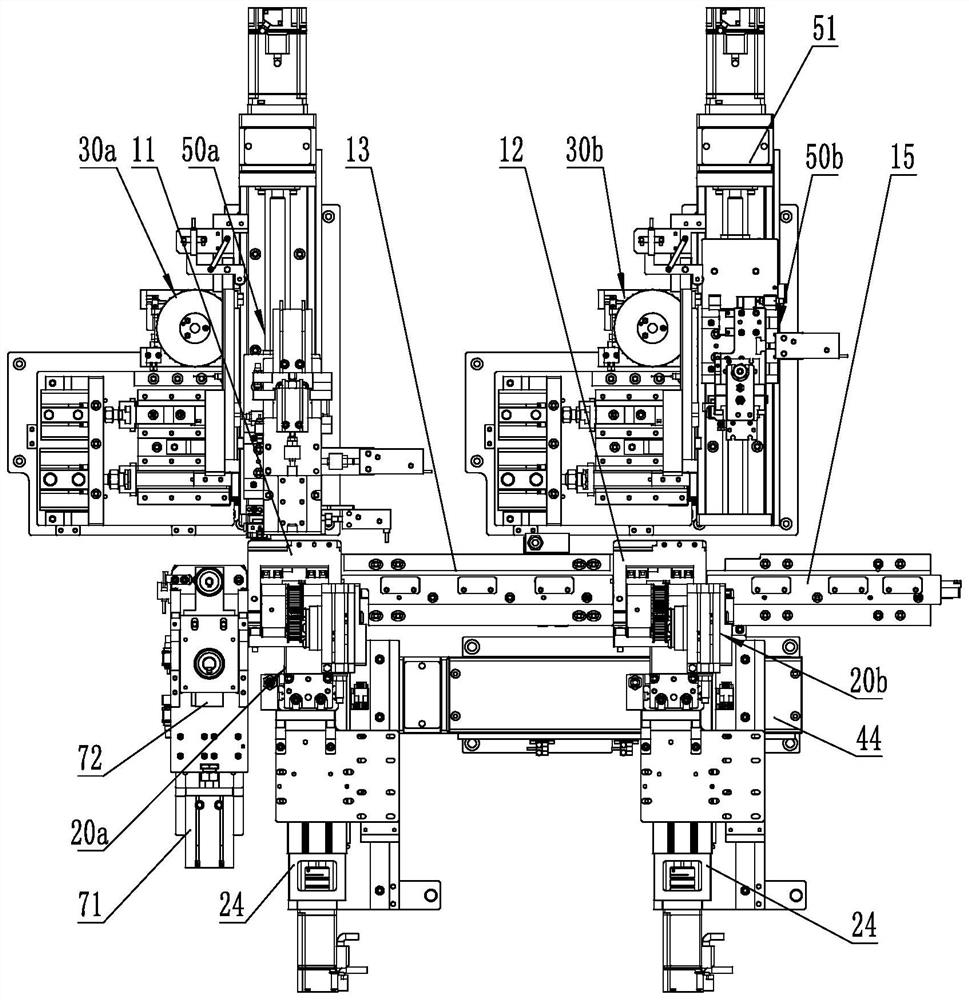

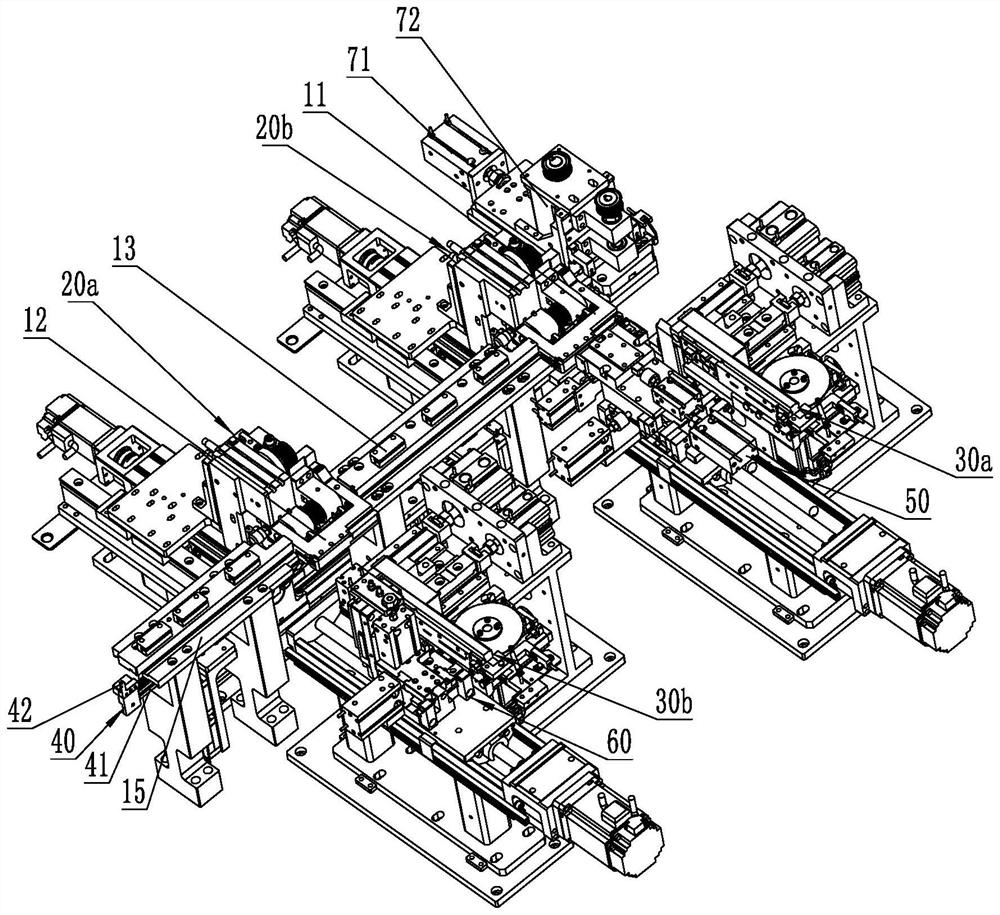

A bonding machine device and a bonding alignment method

ActiveCN103077904BPrecise alignmentReduce low yieldSemiconductor/solid-state device manufacturingBonding processEngineering

The invention relates to a bonding technology for semiconductor manufacture, in particular to a bonding machine device and a bonding alignment method. The bonding alignment method comprises the following steps of: aligning a top alignment camera and a bottom alignment camera with a standard alignment identifier respectively; aligning a top chuck alignment identifier with the bottom alignment camera, and aligning a bottom chuck alignment identifier with the top alignment camera; aligning a top wafer alignment identifier with the top chuck alignment identifier; aligning a bottom wafer alignment identifier with the bottom chuck alignment identifier; aligning the top wafer alignment identifier with the bottom alignment camera, and aligning the bottom wafer alignment identifier with the top alignment camera; and bonding a top wafer and a bottom wafer, which are aligned. According to the bonding machine device and the bonding alignment method, an unknown parameter that whether chucks are aligned or not is substantially eliminated, so that the wafers can be aligned more accurately to solve the problems of low image sensor yield and long alignment time caused by low alignment degree in a bonding process, further improve the yield of an image sensor, reduce the time of the whole bonding process and improve the production efficiency.

Owner:WUHAN XINXIN SEMICON MFG CO LTD

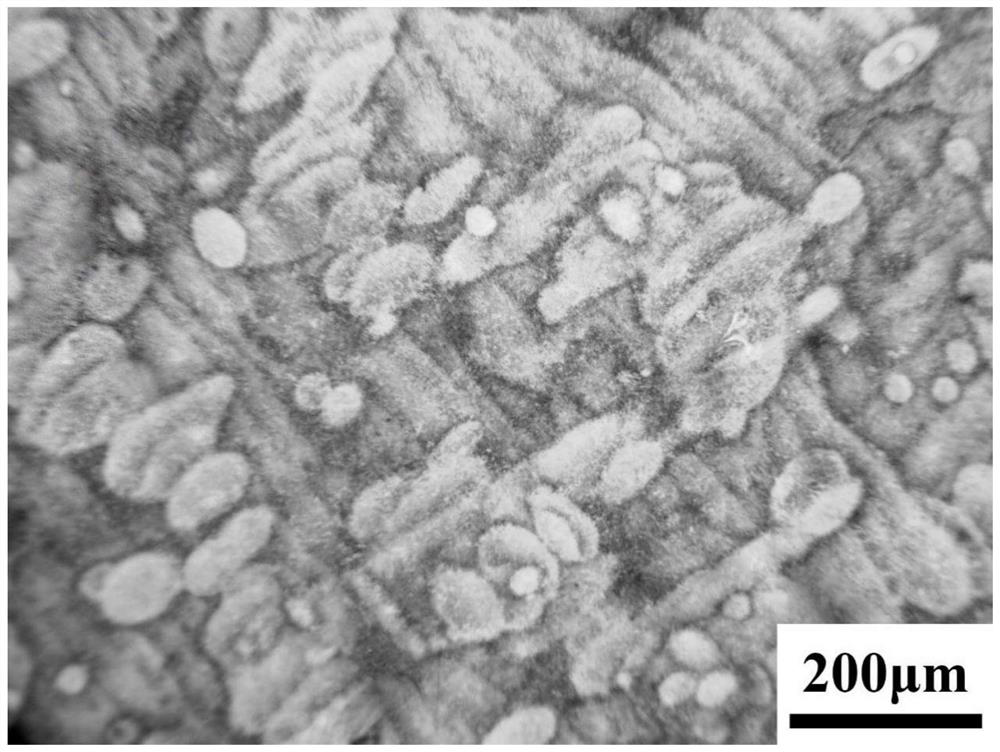

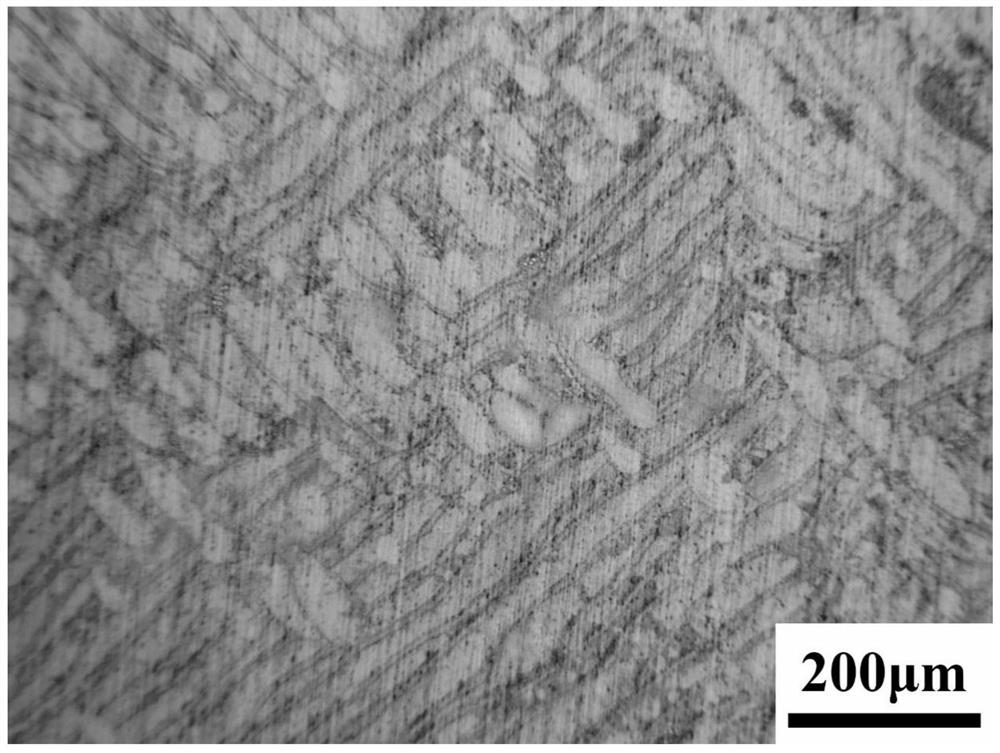

Alloy steel powder for laser additive manufacturing of composite high-speed rail brake disc and manufacturing method

ActiveCN112981253AImprove toughnessGuaranteed toughnessAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingLaser processing

The invention belongs to the technical field of laser additive manufacturing materials, and relates to alloy steel powder for laser additive manufacturing of a composite high-speed rail brake disc. The alloy steel powder comprises matrix powder and strengthened layer powder, the matrix powder is 24CrNiMo low alloy steel powder, and the strengthened layer powder is wear-resistant stainless steel powder. The method for manufacturing the composite high-speed rail brake disc alloy steel comprises the steps that (1) a base plate is pretreated, specifically, austenitic stainless steel is adopted as the base plate, and polishing, sand blasting, ultrasonic cleaning and drying are conducted for standby application; and (2) the two kinds of powder are dried, specifically, matrix deposition layer alloy powder and surface strengthening layer alloy powder are sequentially deposited on the surface of the austenitic stainless steel base plate by the aid of a double-powder-laying optical fiber laser machining system and a selective laser melting method. According to the alloy steel powder and the method, the composite alloy steel which is excellent in matrix obdurability, good in comprehensive performance, high in surface strengthening layer hardness and good in abrasion resistance can be successfully prepared on the austenitic stainless steel base plate.

Owner:SHENYANG POLYTECHNIC UNIV

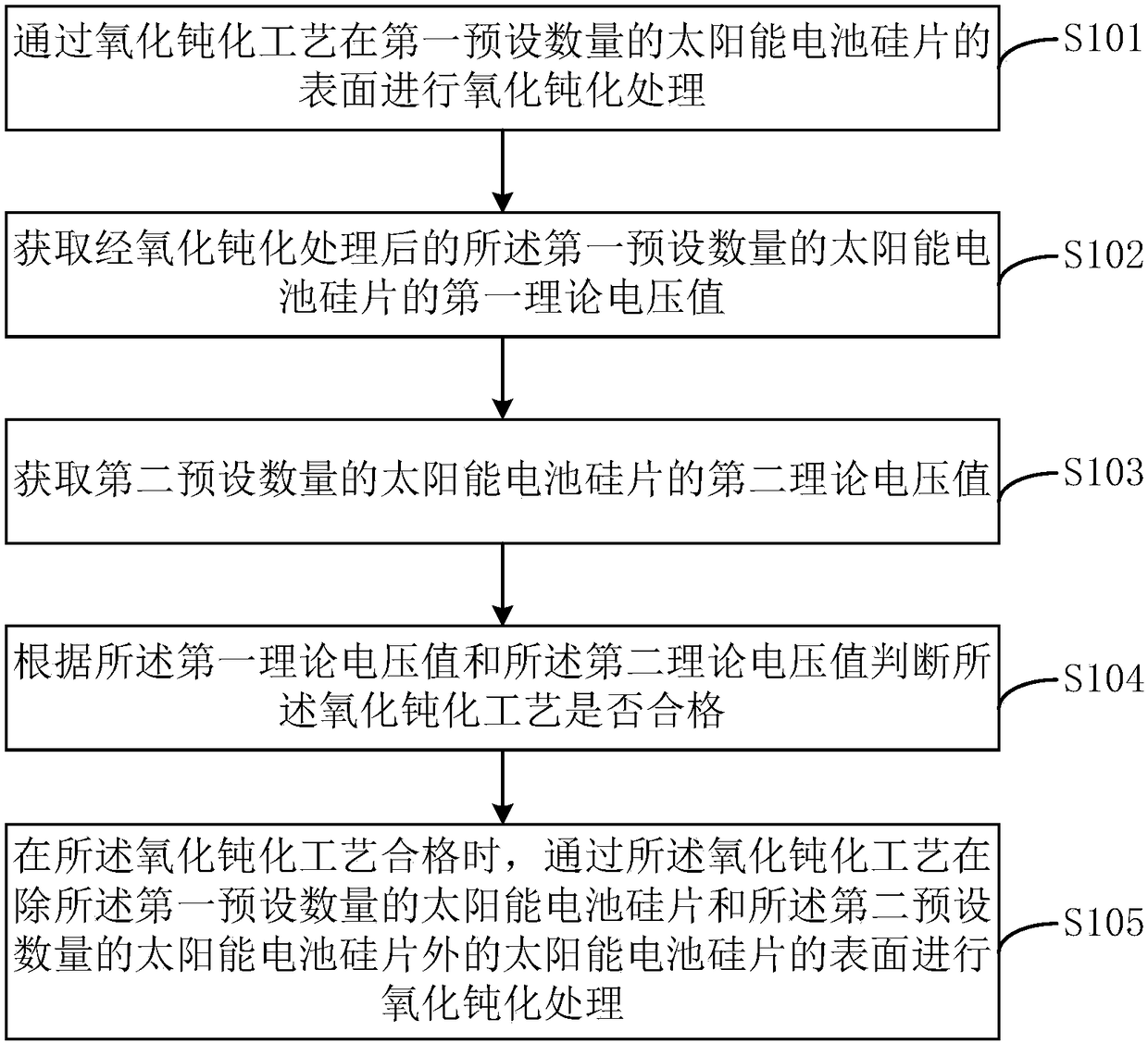

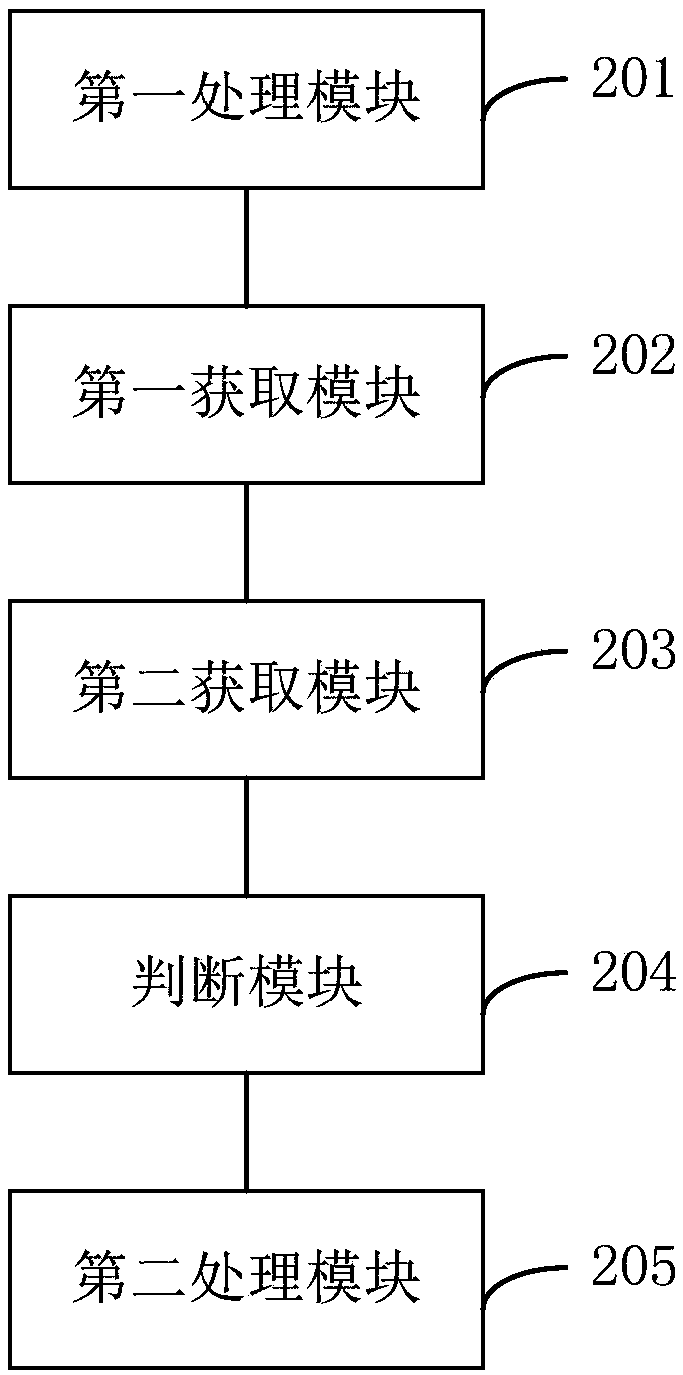

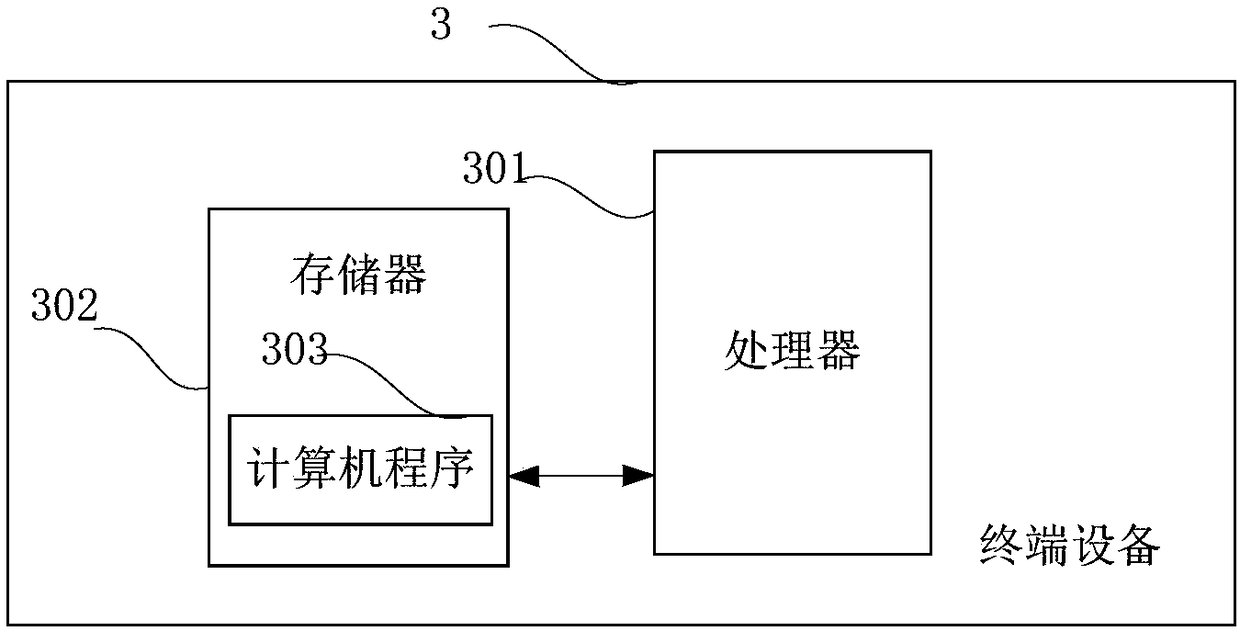

Oxidation passivation method and terminal device for solar cell silicon wafer

ActiveCN108520909ASolve the low yield rateImprove yield rateFinal product manufactureSemiconductor devicesTerminal equipmentSolar cell

The invention is applicable to the field of solar cell technology, and provides an oxidation passivation method and terminal device for a solar cell silicon wafer. The method comprises steps of: performing oxidation passivation treatment on the surfaces of a first preset number of solar cell silicon wafers through the oxidation passivation process; acquiring a first theoretical voltage value of the first preset number of solar cell silicon wafers after the oxidation passivation treatment; acquiring a second theoretical voltage value of a second preset number of solar cell silicon wafers; according to the first theoretical voltage value and the second theoretical voltage value, determining whether the oxidation passivation process is qualified; and when the oxidation passivation process isqualified, performing oxidation passivation treatment on the surfaces of solar cell silicon wafers expect the first preset number of solar cell silicon wafers and the second preset number of solar cell silicon wafers. The method can improve the yield of solar cells.

Owner:YINGLI ENERGY CHINA

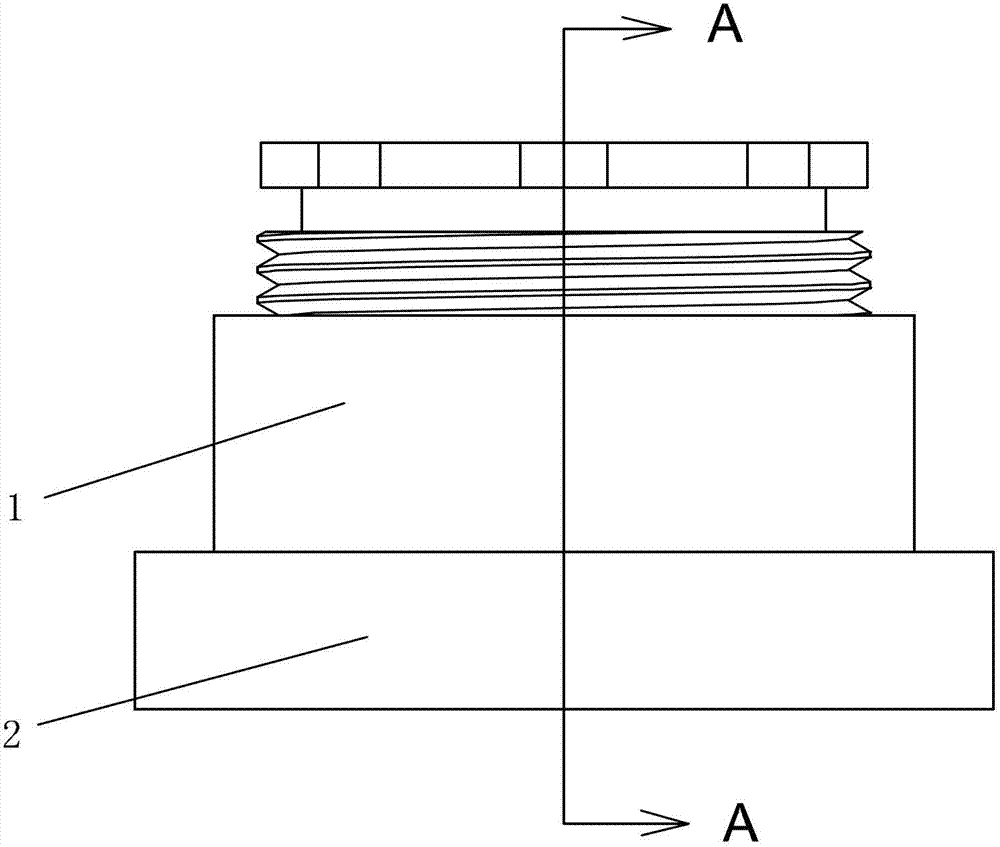

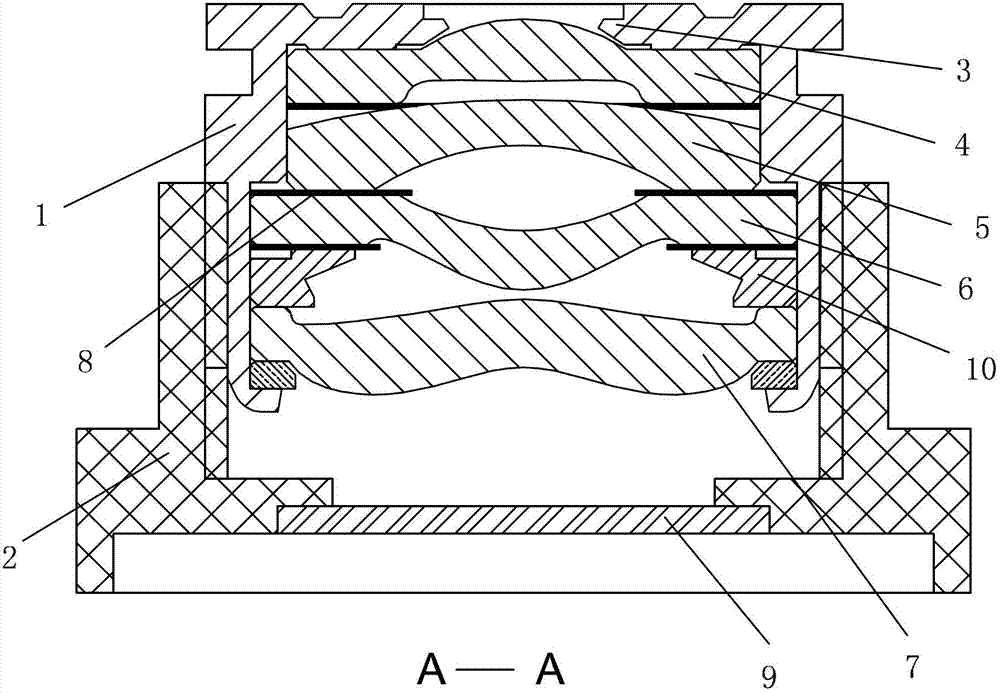

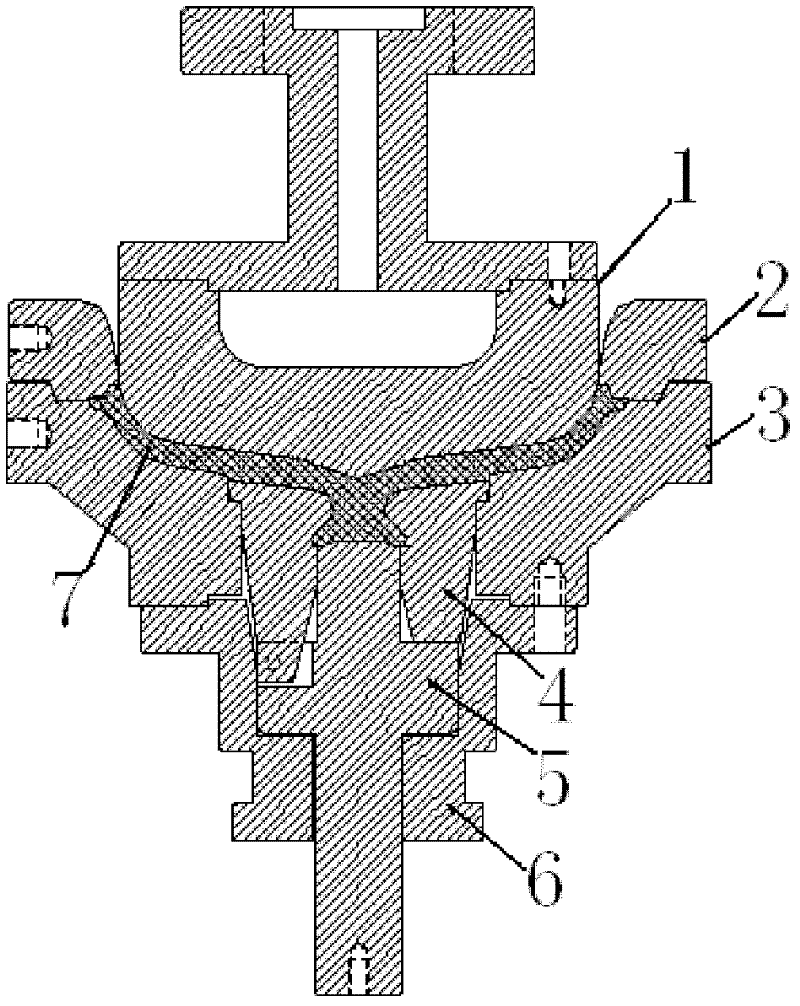

Mould of glassware cover

ActiveCN102515474AQuality improvementImprove work efficiencyGlass pressing apparatusMaterials science

Owner:CHANGSHU JINGGONG MOLD MFG

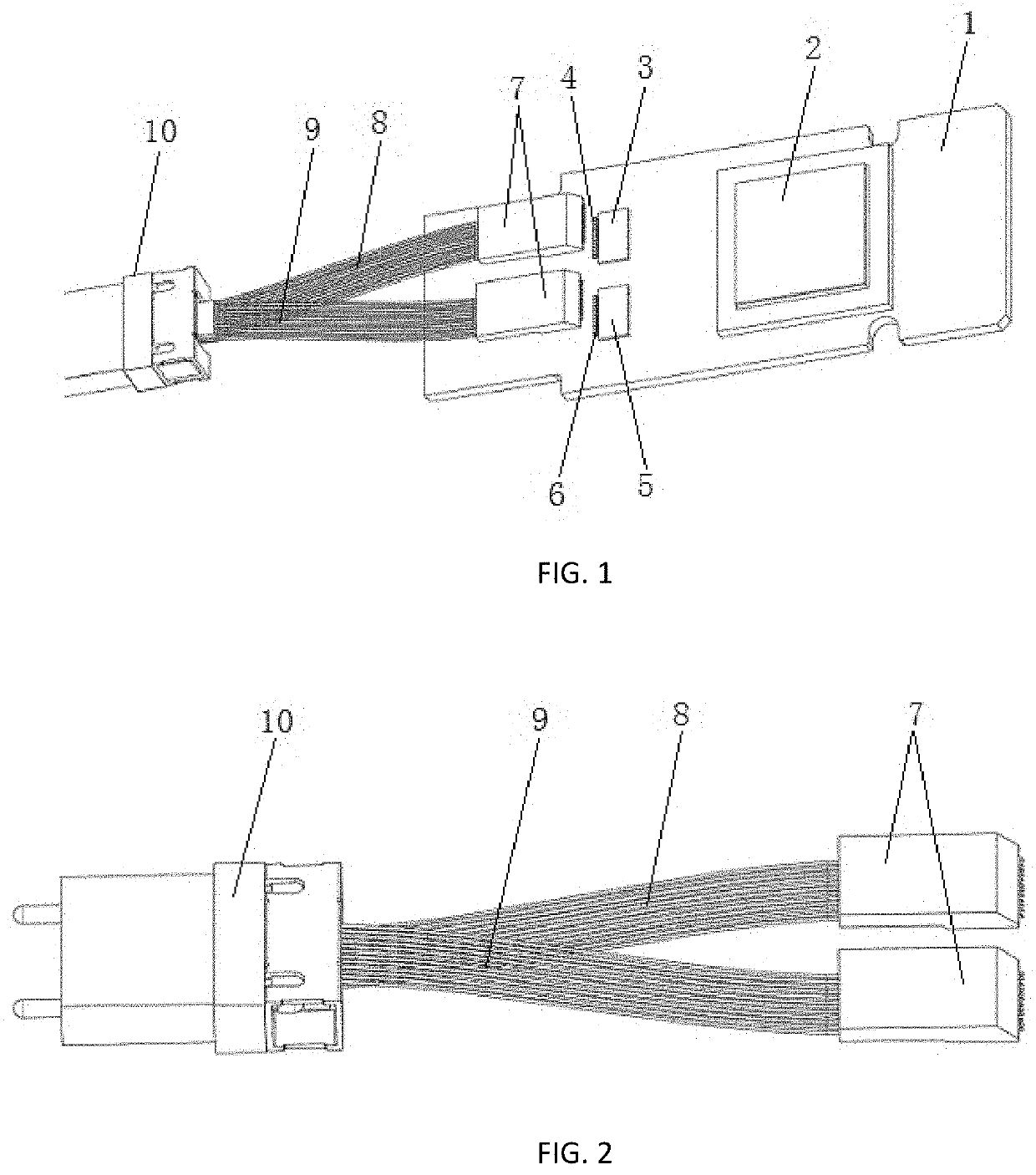

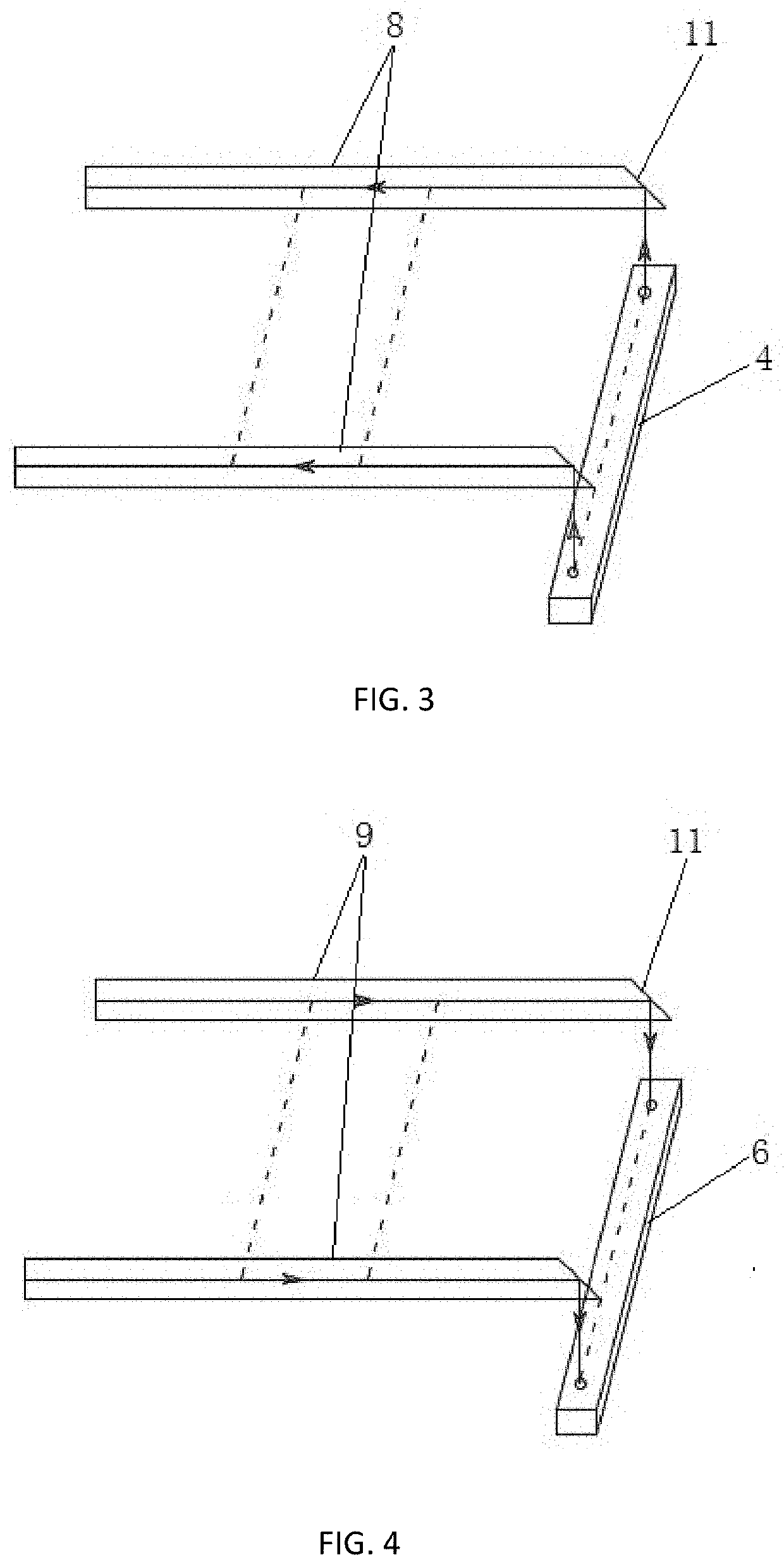

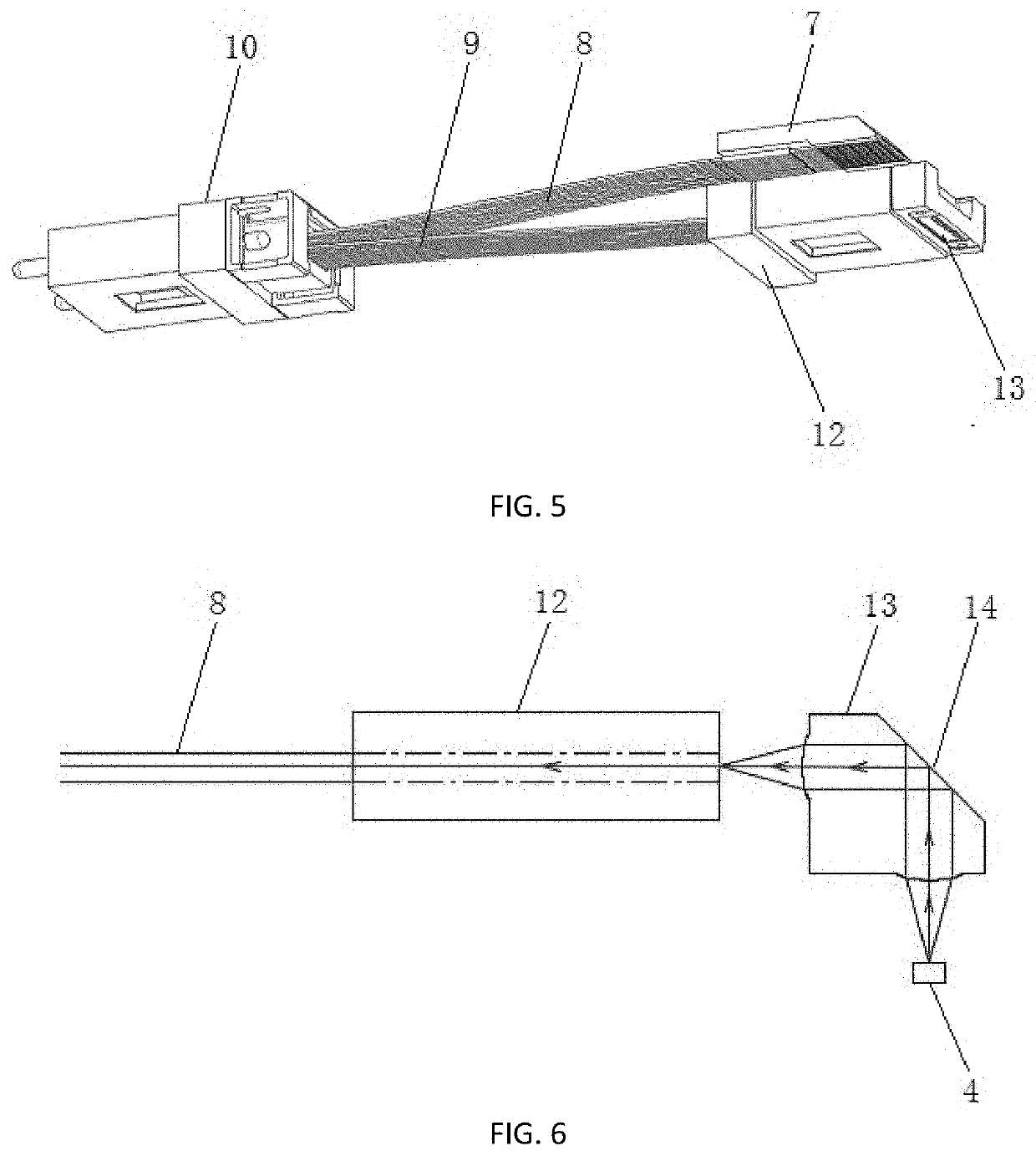

Optical module

ActiveUS20200264392A1Complex to optimizeMinimum optical componentCoupling light guidesFibre mechanical structuresVertical-cavity surface-emitting laserPhotovoltaic detectors

The invention provides an optical module including a circuit board, an optical component and an electrical interface, and the circuit board is provided with a signal rate transmission chip, a laser driver chip, a transimpedance limiting amplifier chip, a vertical cavity surface-emitting laser chip array and a photodetector chip array, and the signal rate transmission chip is electrically connected with the laser driver chip and the transimpedance limiting amplifier chip through the first microstrip line, and the optical component includes an interface end MT ferrule, and a light-emitting ribbon optical cable and a light-receiving ribbon optical cable both connected with the interface end MT ferrule, the light-emitting ribbon optical cable is coupled and aligned with the vertical cavity surface-emitting laser chip array, and the light-receiving ribbon optical cable is coupled and aligned with the photodetector chip array, and the electrical interface includes a gold finger disposed on one side of circuit board. The gold finger and the signal rate transmission chip are electrically connected through the second microstrip line. The present invention achieves a high-density optical package while optimizing the complexity of optical path coupling.

Owner:LINKTEL TECH CO LTD

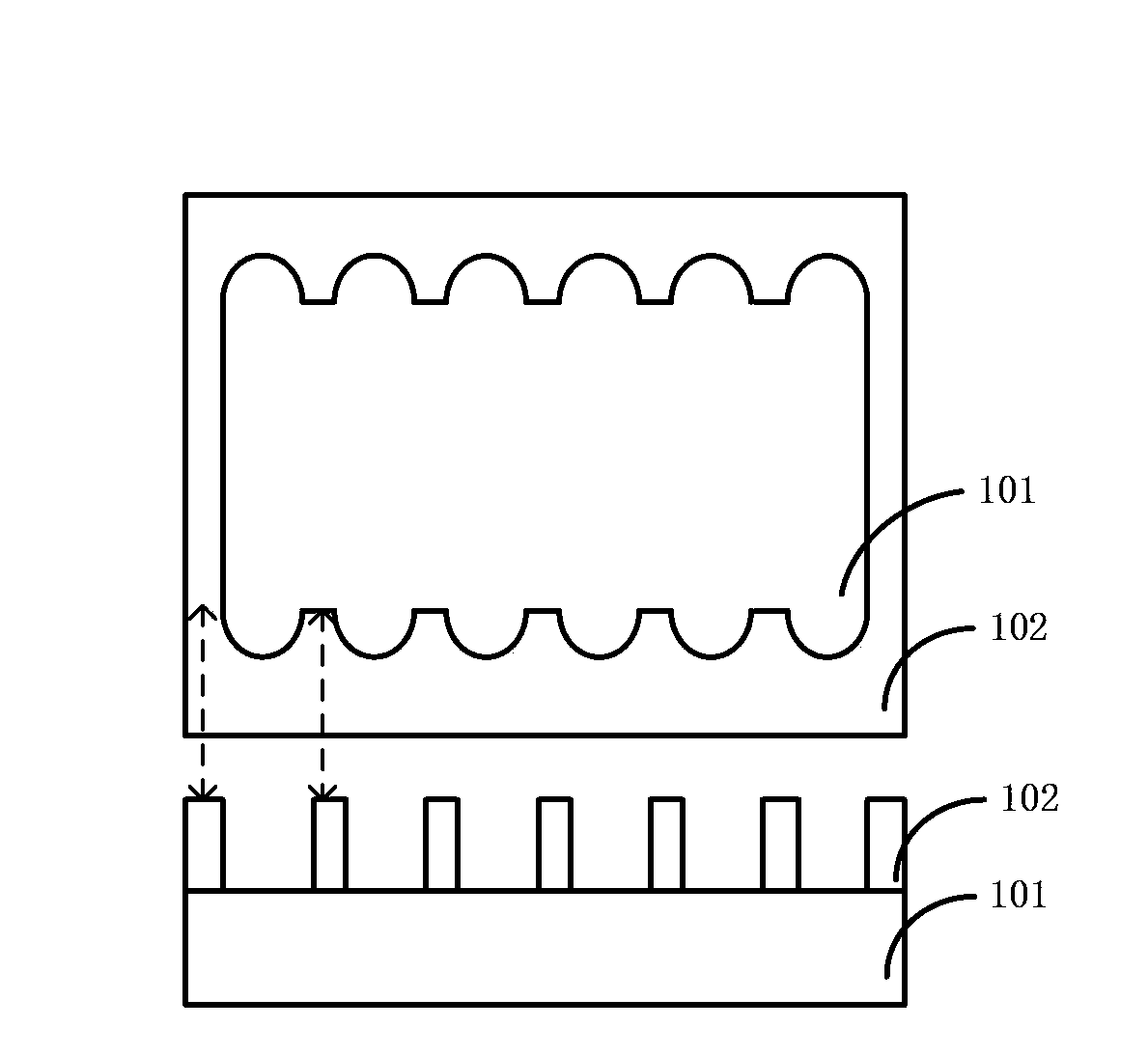

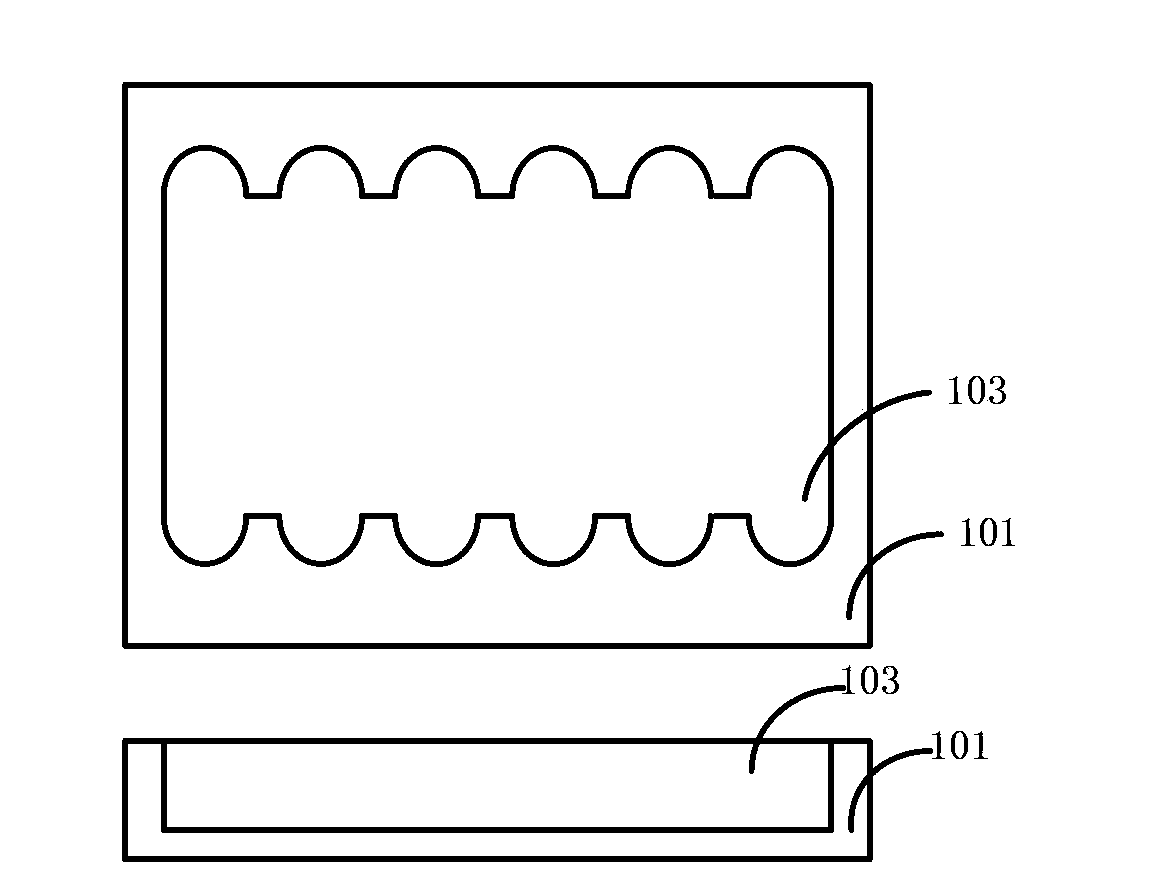

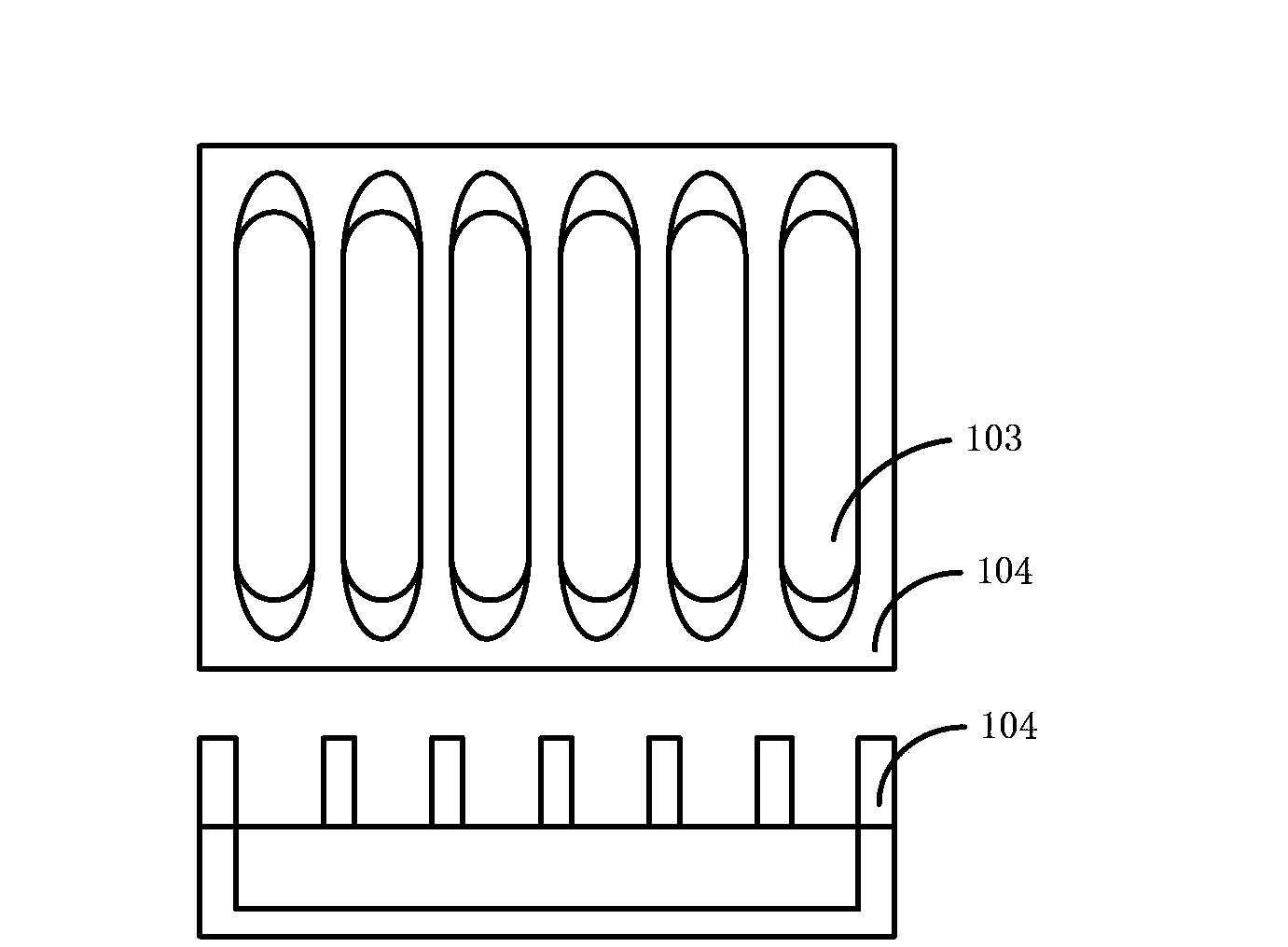

Semiconductor device manufacturing method based on self-aligned double patterning

ActiveCN103779263ASolve the low yield rateFirmly connectedSemiconductor/solid-state device manufacturingEngineeringDielectric layer

The invention relates to a semiconductor device manufacturing method based on self-aligned double patterning. The method comprises the following steps: a back-end-of-line device is provided, and a semiconductor substrate and a dielectric layer located on the semiconductor substrate are at least comprised; the dielectric layer is patterned to remove a part of the dielectric layer and form grooves; an APF material layer is deposited and planarized to fill the grooves; the APF material layer is etched to form grooves and strip-like core lines located between the grooves; a sidewall material layer is deposited on the substrate, and then the sidewall material layer is etched to form spacing walls on sidewalls of the strip-like core lines; and the strip-like core lines are removed through etching to form a parallel strip-like pattern without performing the end cutting step separately. According to the method of the invention, a target pattern can be obtained in the back-end-of-line (BEOL) of the semiconductor device without performing the end cutting step, so the process is simple and easy to control.

Owner:SEMICON MFG INT (SHANGHAI) CORP

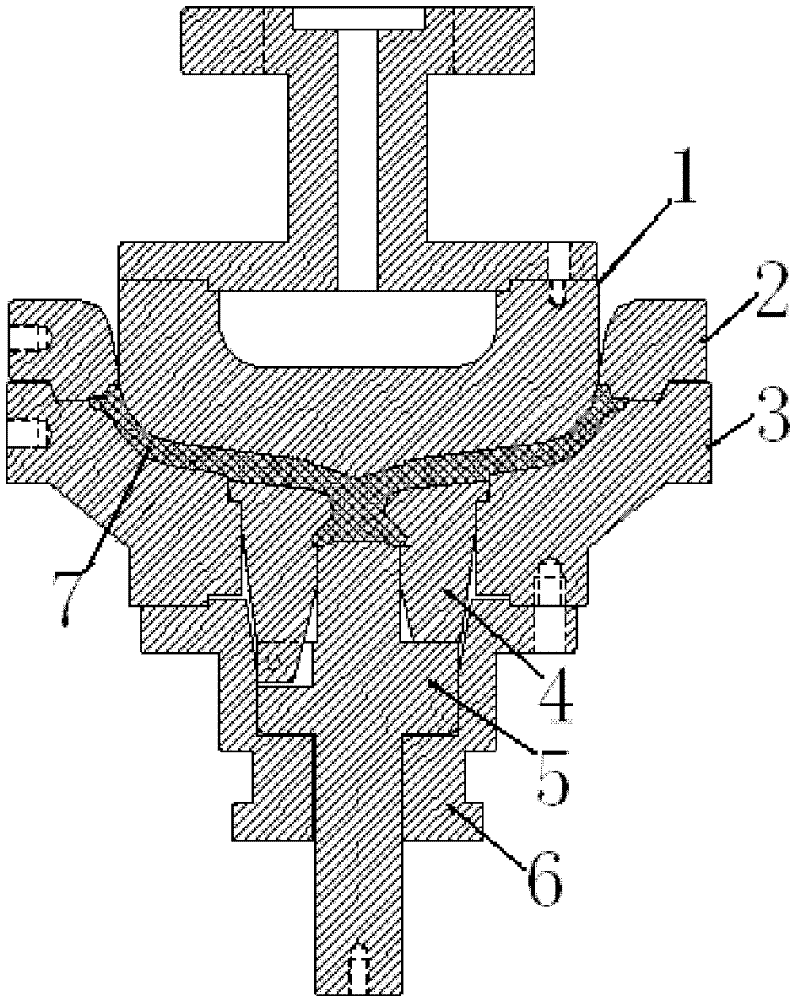

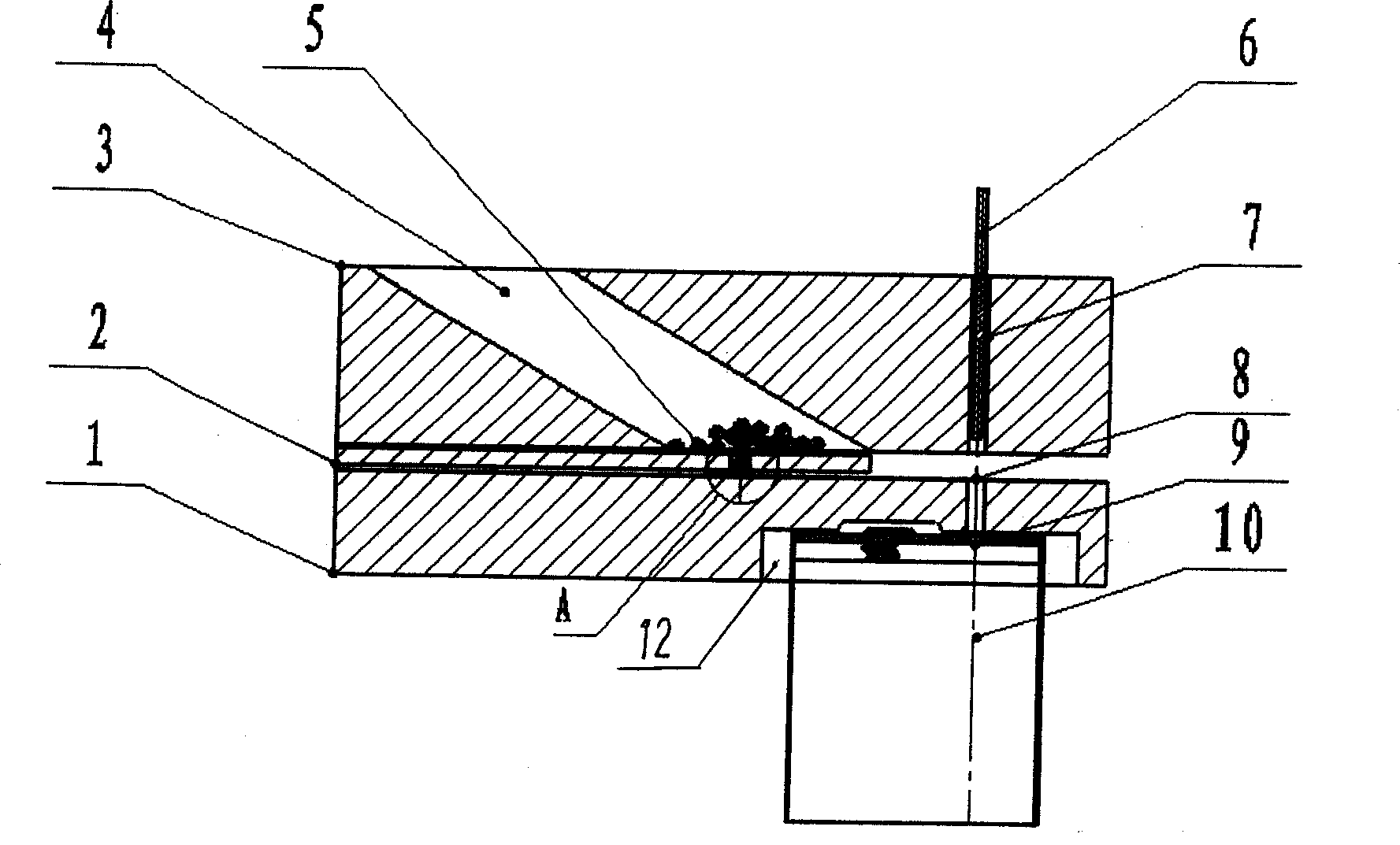

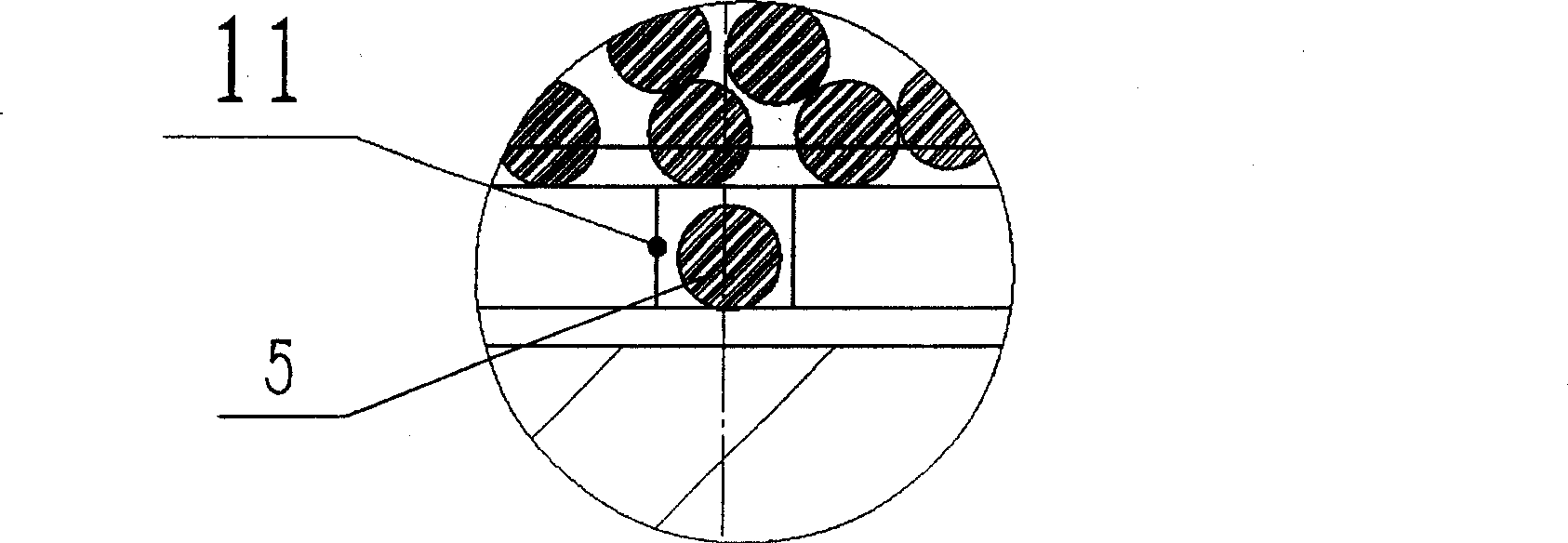

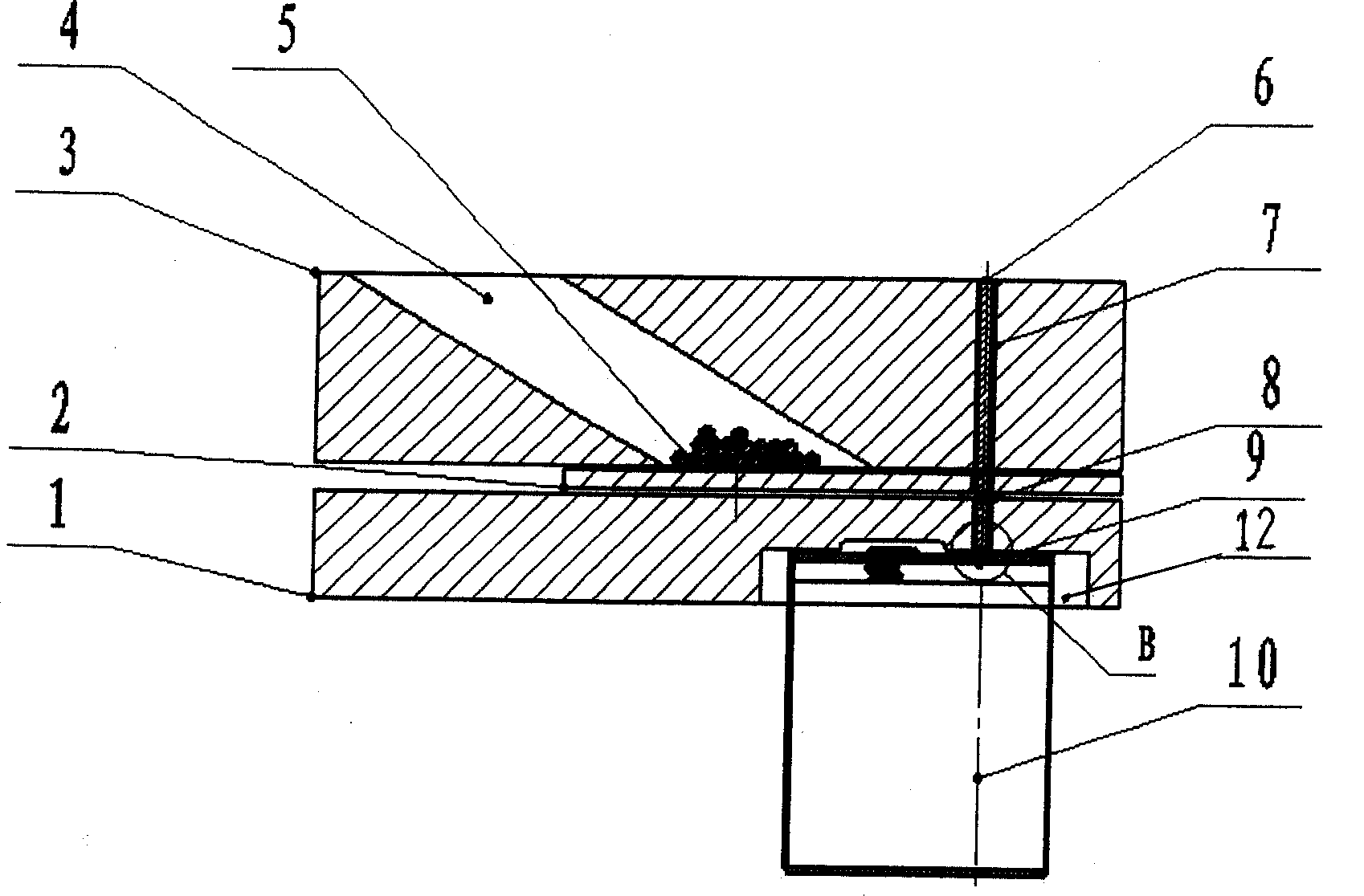

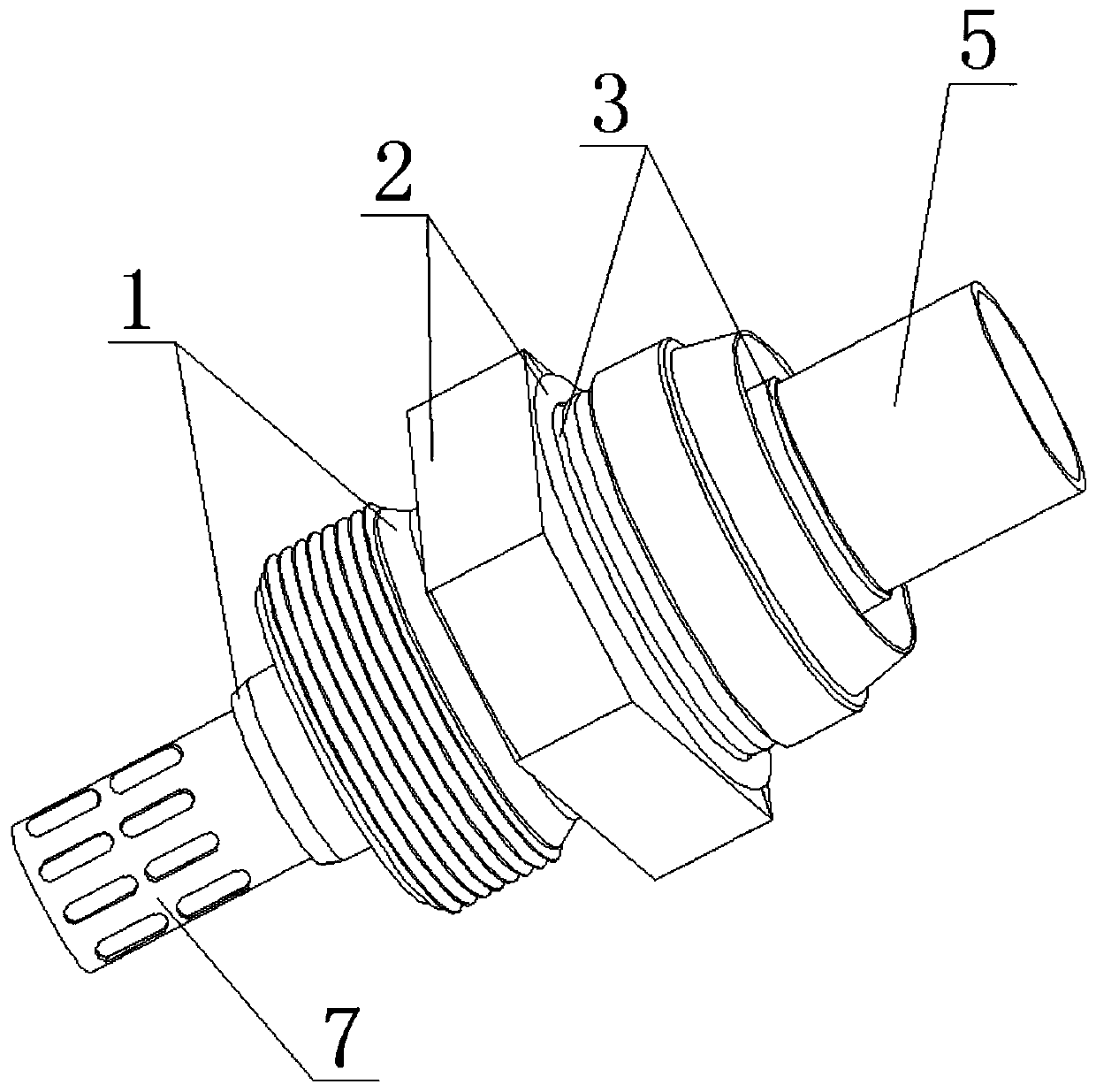

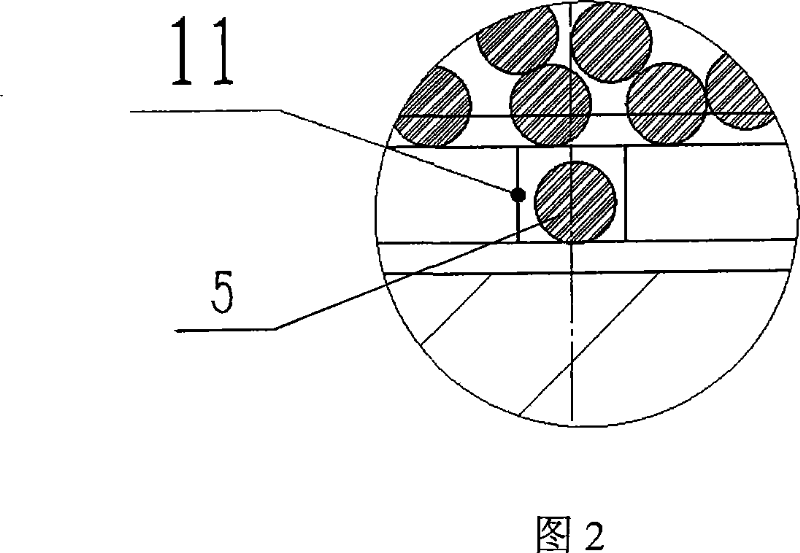

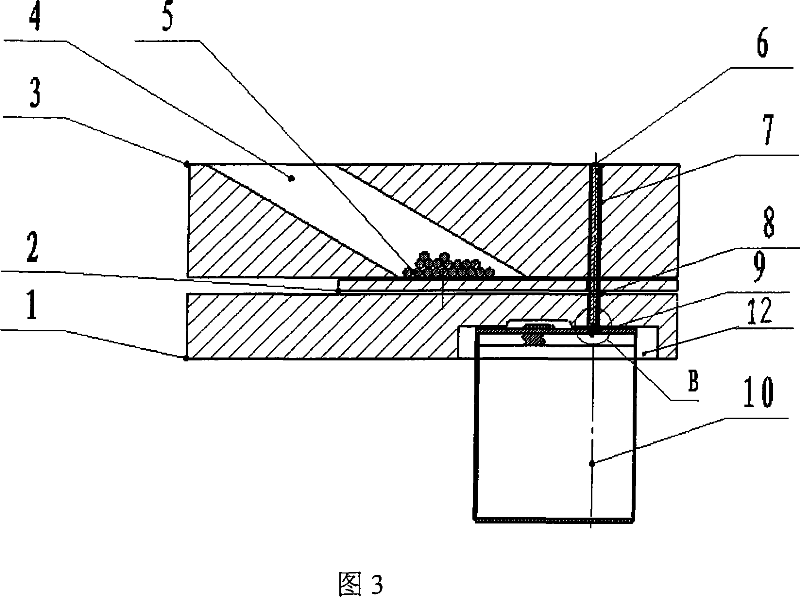

Sealing device for steel ball conveying and press-in of lithium ionic cell

ActiveCN100466334CPrecise deliveryPrevent liquid leakageFinal product manufactureSmall-sized cells cases/jacketsInjection portEngineering

The invention relates to a steel ball transferring pressing seal device for lithium battery, which includes an upper model board and a lower model board which are oppositely disposed and between which a sliding board provided with ball transferring hole is arranged in parallel; the upper model board is provided a ball storage cavity for transferring steel ball which is aslant opened from up to down; one side of the bottom face of the lower model board is provided with a cavity for battery positioning and opened upwards, opposite to which a steel ball inducing hole which vertically drills through the lower board; and opposite to the steel ball inducing hole of the lower board, a pin hammer inducing hole is vertically arranged on the upper model board in coaxial, within which a pin hammer is disposed. In application, the steel ball aslant slides form the ball storage cavity into the transferring hole of the sliding board, and the sliding board drives the steel ball forward to input the same into the steel inducing hole, and then, the steel ball is pressed into a battery injection port by the pin hammer vertical motion via the steel ball inducing hole thereby completing the seal for battery cover. The device is not only suitable for the seal in normal condition, but is also suitable for vacuum seal; and it can automatically transfer and supply the steel balls one by one, accurately position, and has remarkable effect.

Owner:TIANJIN JUYUAN NEW ENERGY TECH CO LTD

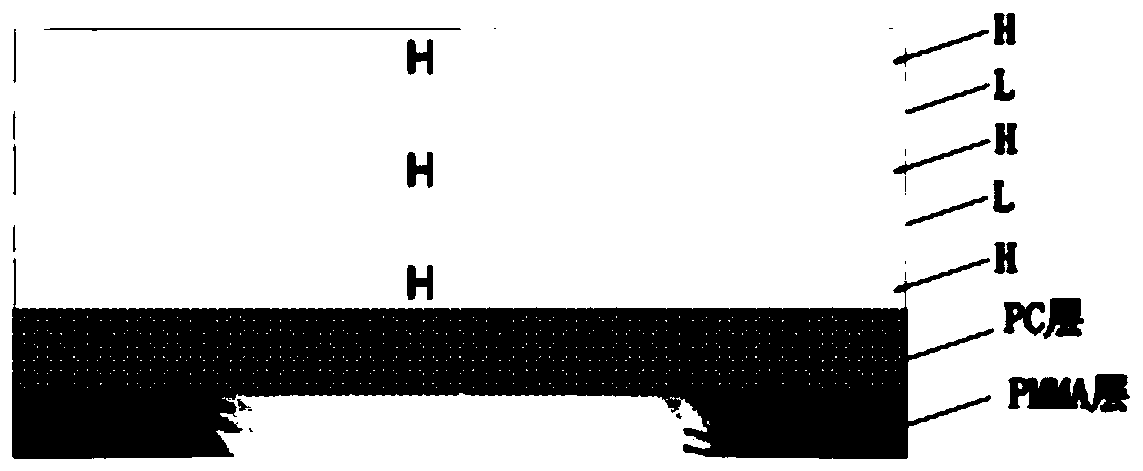

3D composite board and preparation method thereof

ActiveCN111559151ASolve the problem of mass productionSolve the low yield rateSynthetic resin layered productsVacuum evaporation coatingPolymer scienceComposite substrate

The invention relates to a 3D composite board and a preparation method thereof. The preparation method comprises the following steps: carrying out pretreatment on a composite substrate; conducting coating alternately on the pretreated composite substrate by using an electron beam evaporation method and taking a material with the refractive index being 2-3 and a material with the refractive index being 1.4-1.6 as coating materials, wherein the technological parameters of each time of coating include the coating rate which is 0.5-2.5 Angstroms / S; and conducting high pressure or hot bending forming on the coated composite substrate. According to the method, on the basis that the thickness of a color film layer is increased, the phenomenon that cracks occur to the composite board in the high-temperature forming process can be reduced, and the problem that a large number of 3D composite boards with thick color film layers cannot be produced in batch or the yield is low is solved.

Owner:WEIDALI IND CHIBI CO LTD +1

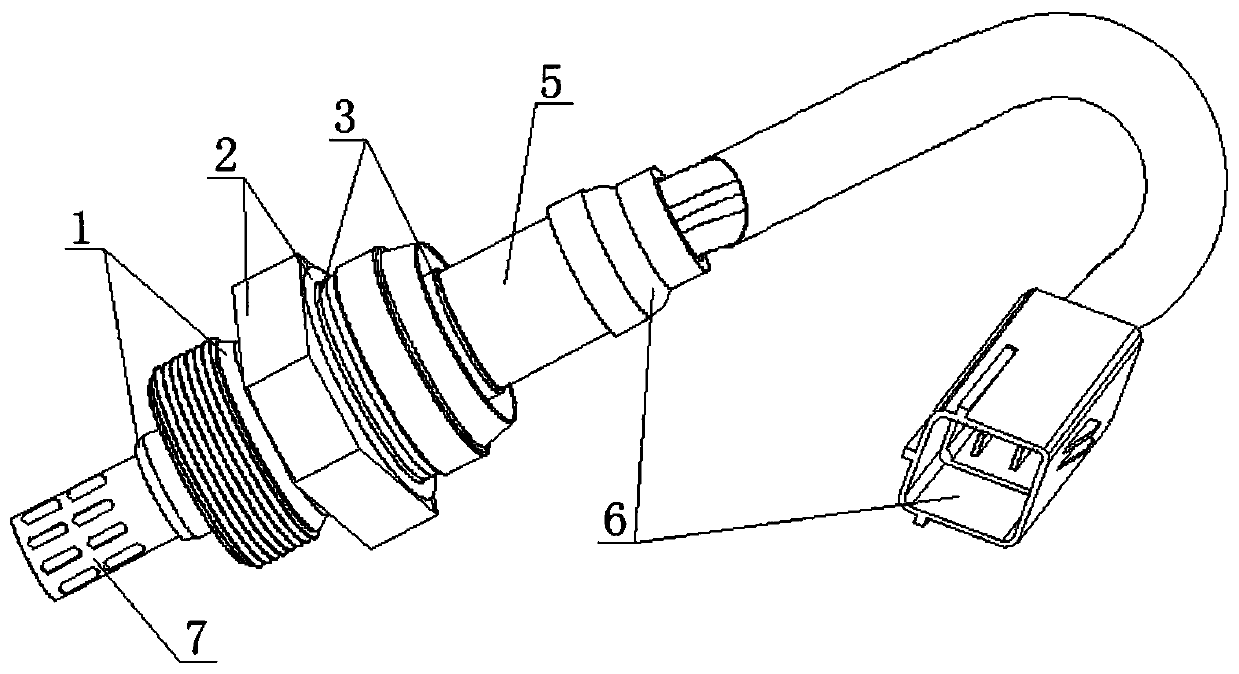

Special inward buckling gas-leak-proof hexagonal seat for oxygen sensors

InactiveCN109856322AImprove air tightnessImprove yieldMaterial analysisEngine lubricationOxygen sensorGas leak

The invention discloses a special inward buckling gas-leak-proof hexagonal seat for oxygen sensors, which is characterized in that the hexagonal seat includes a front threaded area, a hexagonal seat area and a rear positioning area, the hexagonal seat area is located between the front threaded area and the rear positioning area, and the hexagonal seat area is connected with the front threaded areaand the rear positioning area as a whole. The hexagonal seat of the invention is of an integral structure, has high overall strength, can ensure good overall gas tightness of oxygen sensors and greatly improve the yield of oxygen sensors, and is suitable for popularization and application in the production and manufacture of automobile oxygen sensors.

Owner:苏州忻智铭传感电子科技有限公司

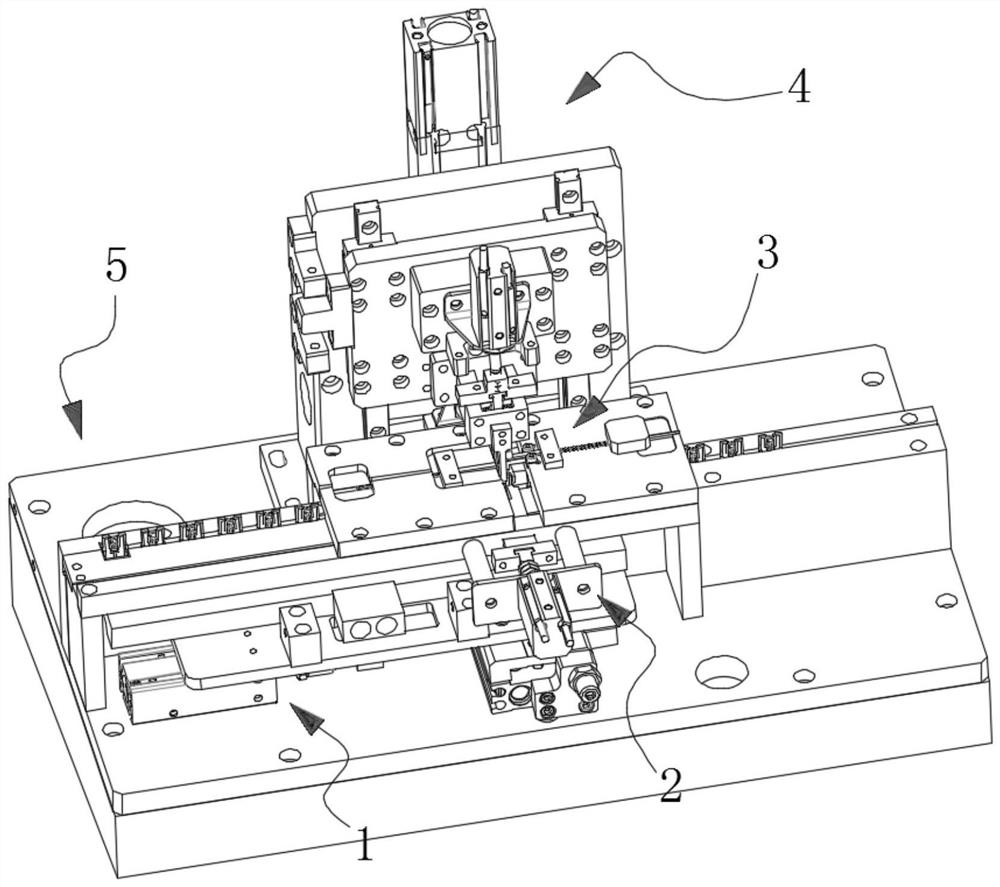

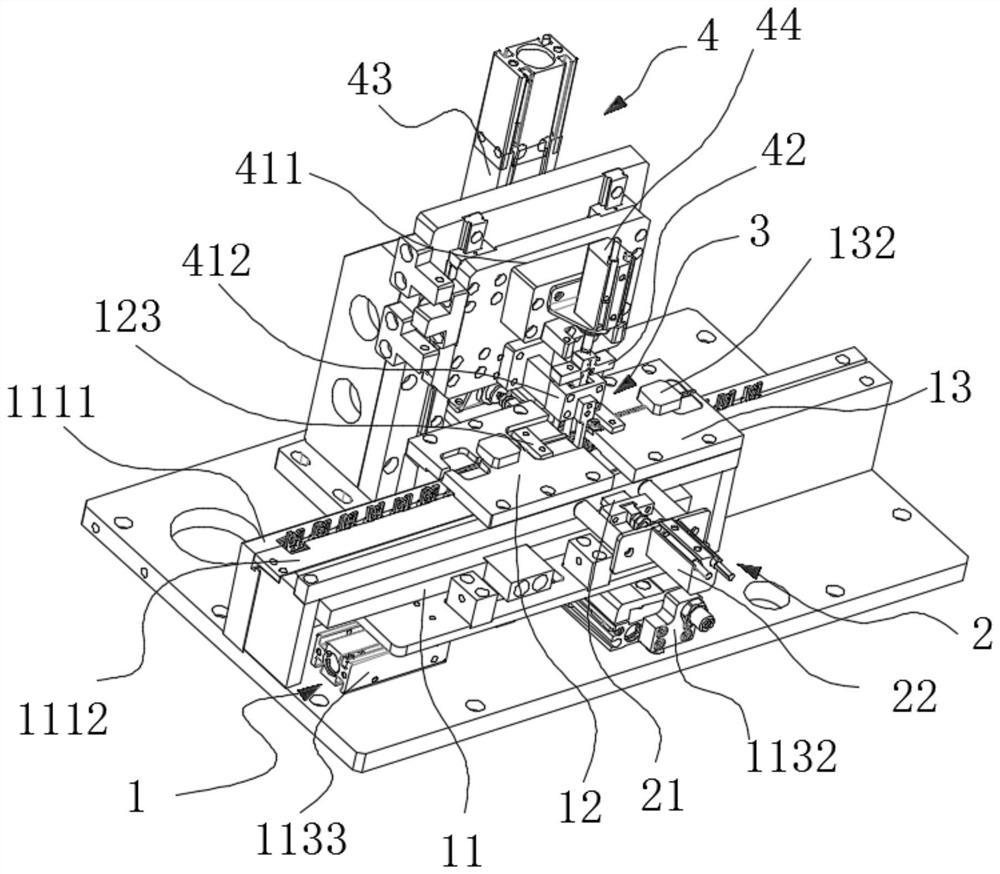

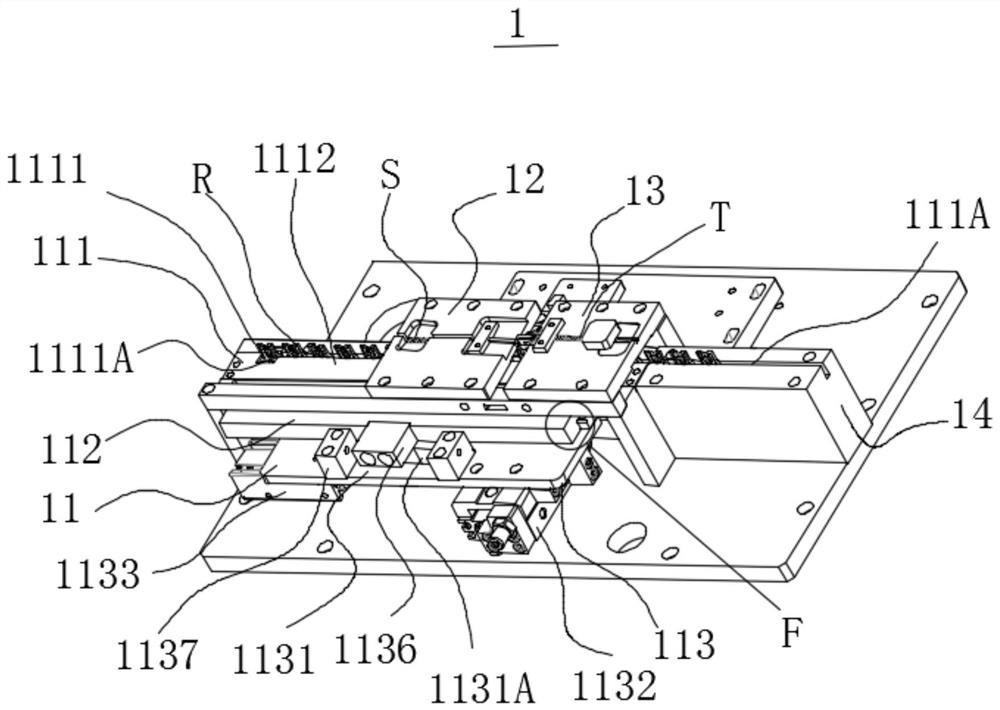

Sleeving core sheet inserting machine

PendingCN114694939AImprove assembly efficiencyImprove assembly qualityMagnetic core manufactureInductorMachine

The invention discloses a core sleeving and sheet inserting machine which is used for assembling an inductor device, the inductor device comprises a coil, a sheet inserting seat, an iron core and a magnet, the coil and the sheet inserting seat are assembled to form a coil sheet inserting seat, and the core sleeving and sheet inserting machine comprises a conveying device, a positioning device, a clamping device and a press fitting device. The conveying device is configured to convey the coil inserting piece base, the iron core and the magnet to the press-fitting position, the positioning device is configured to position the coil inserting piece base located at the press-fitting position, and the clamping device is configured to clamp the iron core and the magnet located at the press-fitting position. And the press-fitting device is configured to press the iron core located at the press-fitting position on the coil insertion piece seat and press the magnet located at the press-fitting position into the iron core on the coil insertion piece seat. Through the combined action of the conveying device, the positioning device, the clamping device and the press-fitting device, the assembling efficiency and quality of the inductor device can be improved, so that the problems of low efficiency and low yield in the manual assembling process are solved, and the productivity of the inductor device is improved.

Owner:湖北铭科达自动化设备有限公司

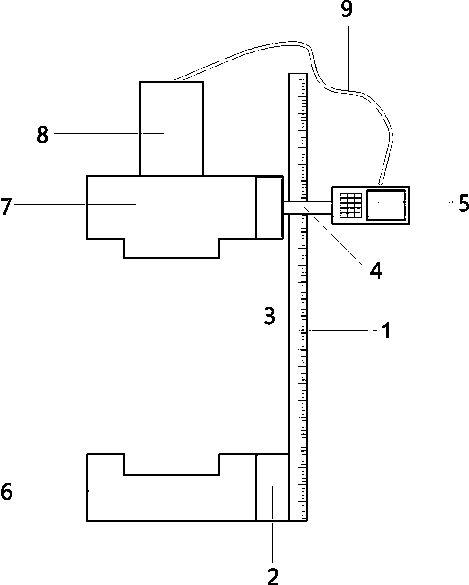

Stroke control device of press machine of automobile sheet metal component

The invention provides a stroke control device of a press machine of an automobile sheet metal component. The stroke control device comprises a scaleplate, a lower fixing plate, an upper fixing plate, a cursor, a control / output panel, a female die, a male die, the press machine and a signal transmission line. When the press machine drives the male die to move, the cursor slides on the scaleplate under driving of the upper fixing plate, the control / output panel displays the scale where the cursor is located, the extension length of the press machine is regulated through the control / output panel according to the forming condition of the sheet metal component between the male die and the female die, and therefore accurate control over the stroke of the press machine is achieved.

Owner:安徽振华汽车部件有限责任公司

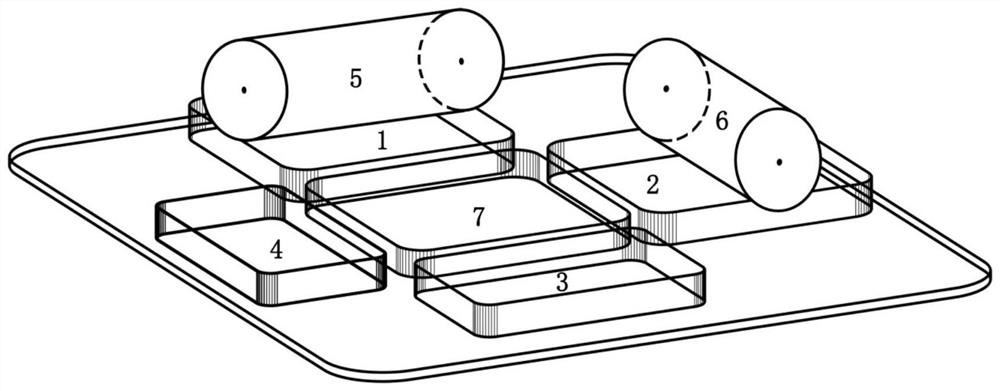

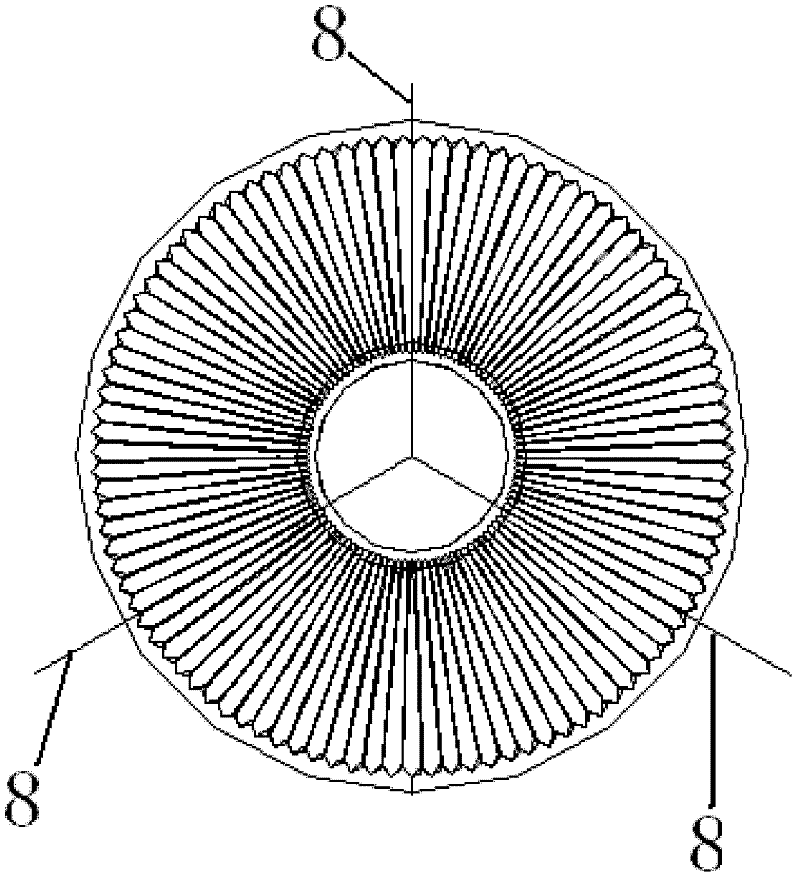

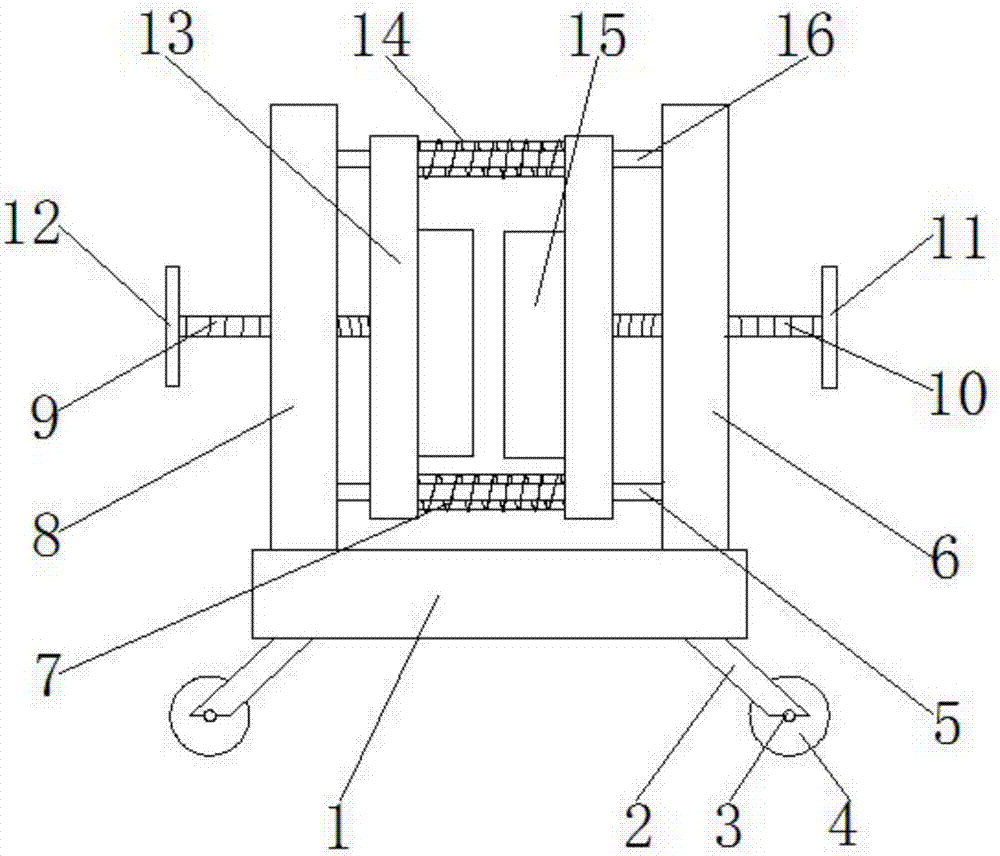

Die cutting bottom roller, die cutting assembly and automatic die cutting machine

PendingCN114102753AGuaranteed separation effectDie-cutting in batchesMetal working apparatusStructural engineeringMachine

The invention discloses a die-cutting bottom roller, which belongs to the field of die-cutting machines, and comprises a roller body, the surface of the roller body is provided with a cutting avoiding groove and an air suction hole, a die-cutting knife roller can be matched with two bottom rollers or a plurality of bottom rollers for multi-time die cutting, and the problem of low yield caused by incomplete waste removal during one-time forming of a film material can be avoided. The invention further discloses an automatic die-cutting machine, the automatic die-cutting machine comprises a die-cutting bottom roller and a knife roller which are fixed on a knife rest, the die-cutting bottom roller comprises a first bottom roller and a second bottom roller, the knife roller is located between the first bottom roller and the second bottom roller, and the knife roller is provided with an outer contour cutting edge and an inner contour cutting edge. The surface of the first bottom roller is provided with an outer contour cutting avoiding groove corresponding to the position of an outer contour blade of the knife roller. According to the automatic die-cutting machine, the design of the die-cutting bottom rollers is optimized, a compact and smooth two-bottom-roller and one-knife-roller structure is adopted, the working efficiency can be 1.5 times or above that of equipment of the same type, the waste material removing effect is remarkable, the rate of finished products can reach one hundred percent, and the automatic die-cutting machine can be applied to machining of mask materials, eye masks and the like.

Owner:广州鸣威智能科技有限公司

Die-casting die fixing device

The invention discloses a die-casting die fixing device which comprises a base. The upper surface of the base is fixedly connected with a first fixing plate and a second fixing plate correspondingly,and the second fixing plate is located at the right side of the first fixing plate. One side of the first fixing plate is fixedly connected with a first slide bar and a second slide bar correspondingly, and the first slide bar is located below the second slide bar. A first threaded hole is formed in the side surface of the first fixing plate, the inner wall of the first threaded hole is in threaded connection with a first threaded rod, one end of the first threaded rod is fixedly connected with a first handle, a second threaded hole is formed in the side surface of the second fixing plate, theinner wall of the second threaded hole is in threaded connection with a second threaded rod, and one end of the second threaded rod is fixedly connected with a second handle. According to the die-casting die fixing device provided by the invention, by arranging the first threaded rod and the second threaded rod, products produced through a die-casting die have no gap, and the problem that the yield of the products produced through the die-casting die is not high is solved.

Owner:NANJING JIAMING DIE CASTING FACTORY

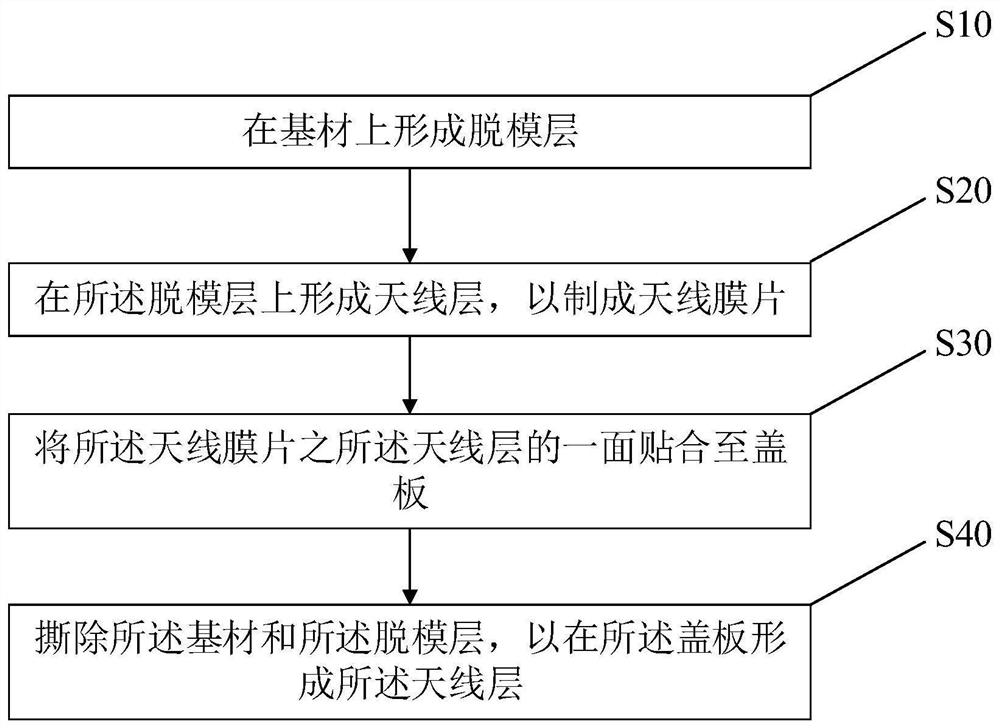

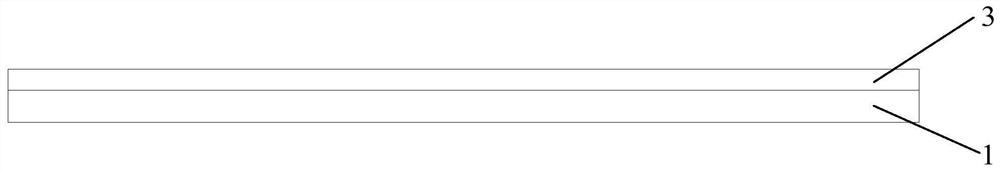

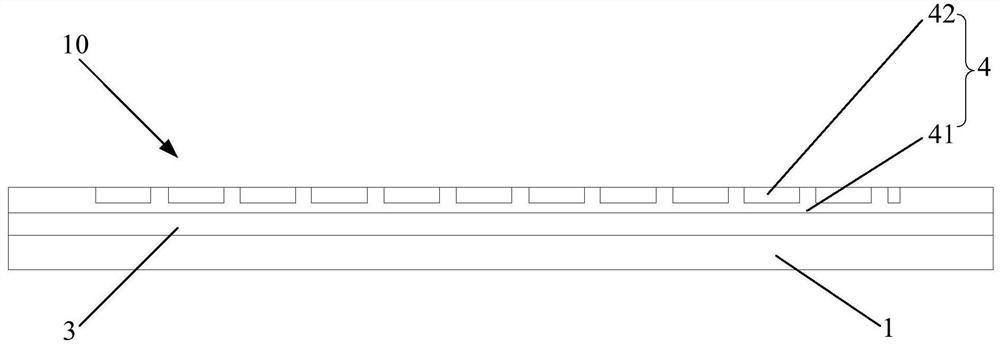

Manufacturing method of antenna cover plate and electronic equipment

InactiveCN112776445ASolve the low yield rateSimple preparation processLamination ancillary operationsAntenna supports/mountingsStructural engineeringMechanical engineering

The invention discloses a manufacturing method of an antenna cover plate and electronic equipment, and the method comprises the steps of: forming a demolding layer on a substrate; forming an antenna layer on the demolding layer to prepare an antenna diaphragm; attaching one surface of the antenna layer of the antenna diaphragm to a cover plate; and tearing off the substrate and the demolding layer so as to form the antenna layer on the cover plate. According to the technical scheme, the antenna diaphragm is firstly manufactured, then the antenna diaphragm is attached to the cover plate, and finally the substrate and the demolding layer of the antenna diaphragm are torn off, so that the antenna layer of the antenna diaphragm is transferred to the cover plate, and the manufacturing process of the antenna cover plate is simple and high in yield. Through the manufacturing method, the antenna layer can be placed at any position of the shell of the electronic equipment, the appearance is not influenced, the signal is enhanced, and the transmission / receiving effect is good.

Owner:NANCHANG O FILM DISPLAY TECH CO LTD

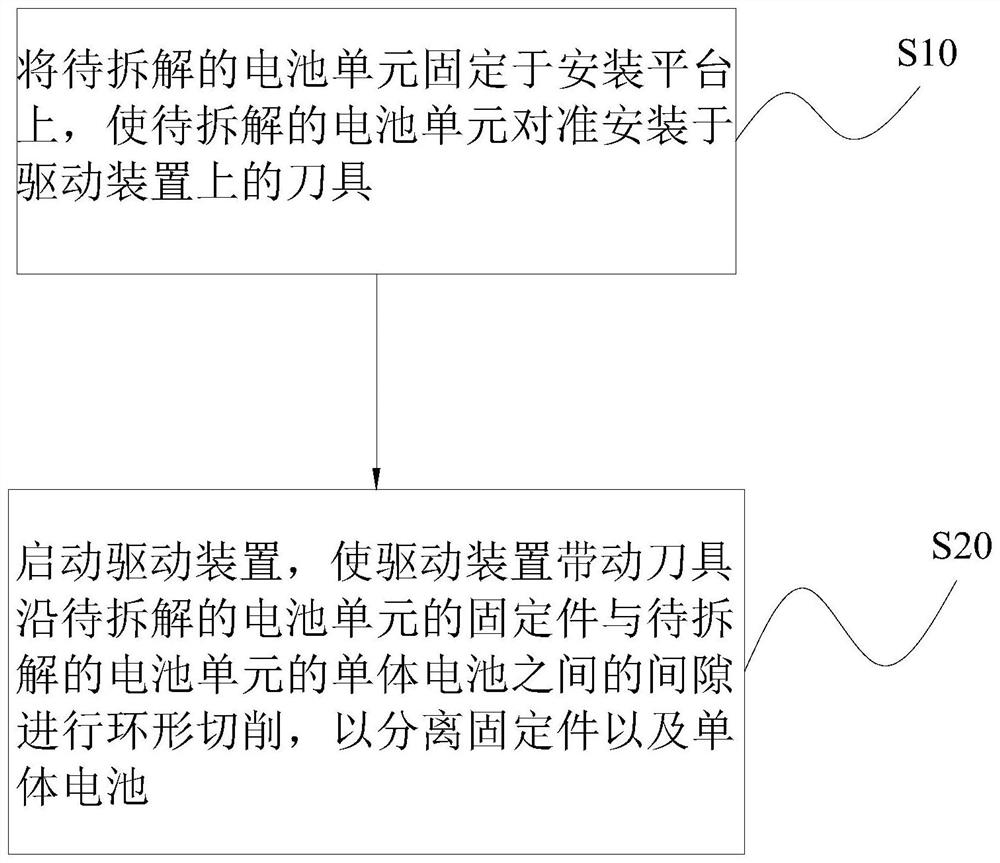

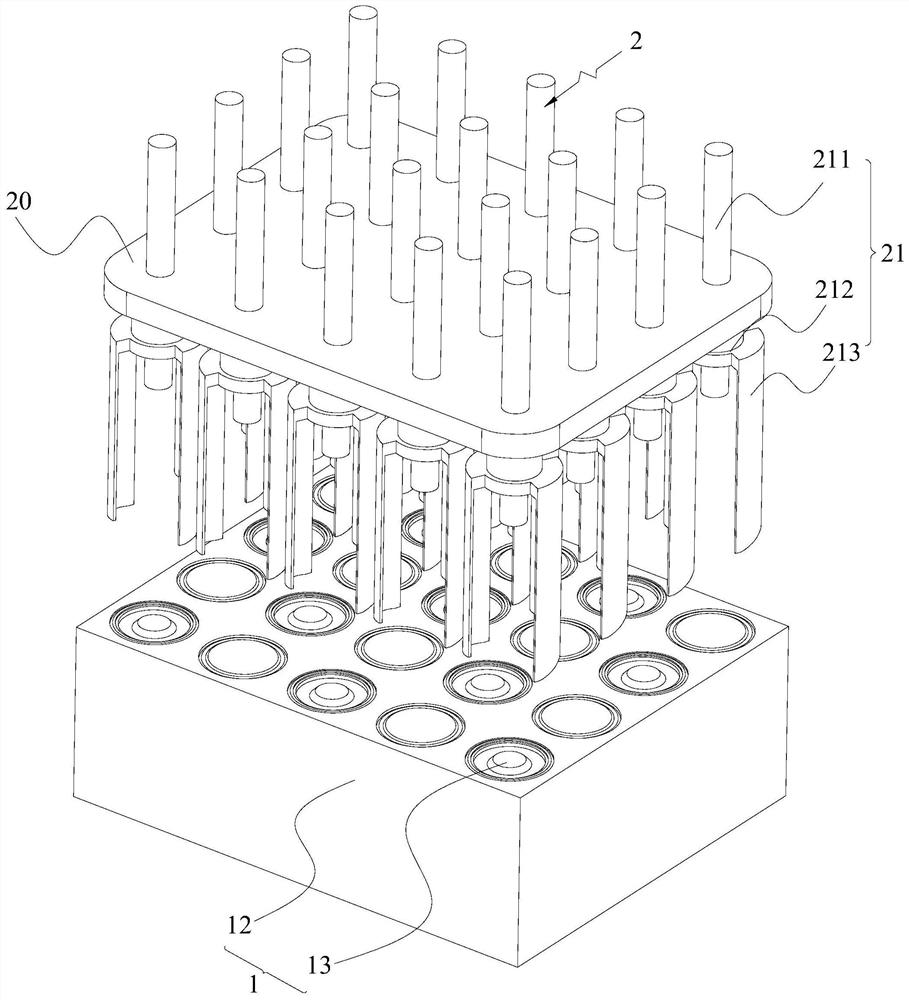

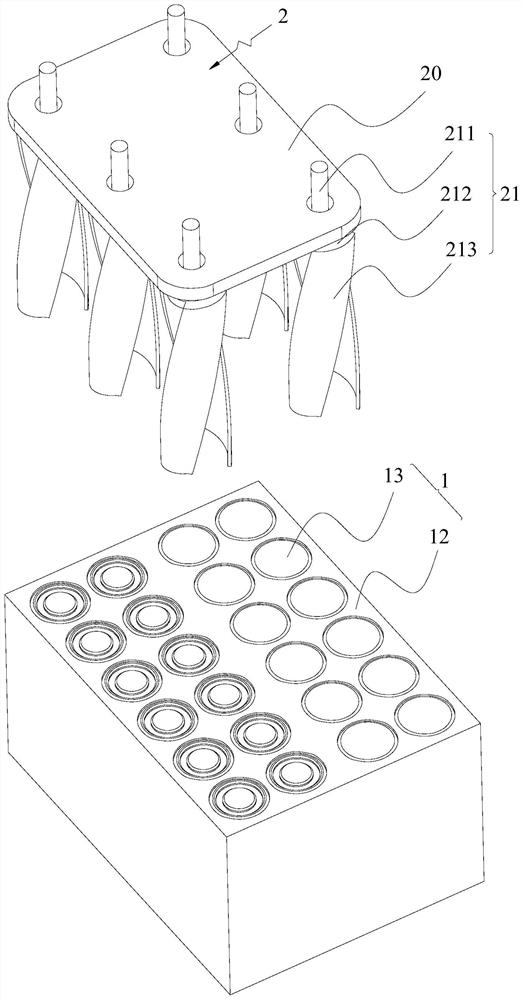

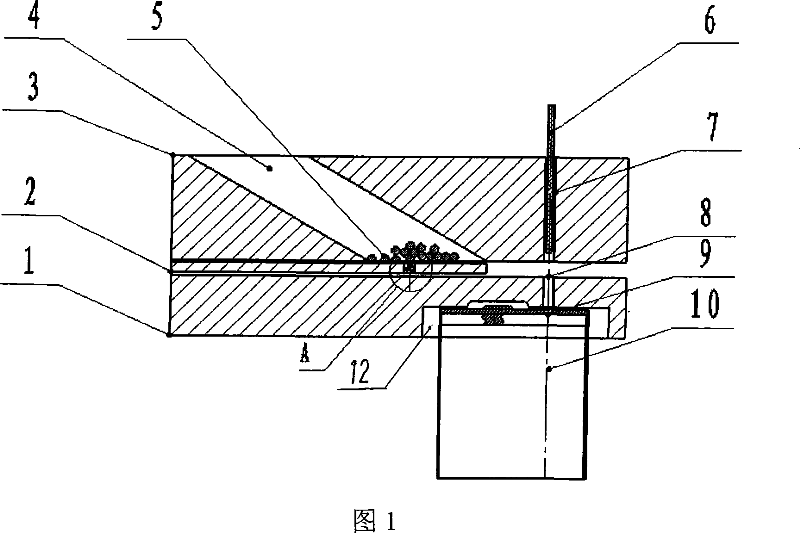

Method for non-destructively disassembling battery cell and cutter used by method

PendingCN111872481AAvoid destructionSolve the low yield rateWaste accumulators reclaimingFeeding apparatusMechanical engineeringBattery cell

The invention is applicable to the technical field of waste battery recovery, and provides a method for non-destructively disassembling a battery cell and a cutter used by the method. The method comprises the following steps: S10, fixing a battery unit to be disassembled on a mounting platform, and aligning the battery unit to be disassembled with the cutter mounted on a driving device; and S20, driving the driving device to enable the driving device to drive the cutter to perform annular cutting along a gap between a fixing piece of the battery unit to be disassembled and the battery cell ofthe battery unit to be disassembled, so as to separate the fixing piece from the battery cell. According to the method for non-destructively disassembling the battery cell, the cutter is driven by thedriving device to perform cutting along the gap between the fixing piece and the battery cell, that is, a cutter unit cuts off the fixing piece along the outer side of the battery cell, so that the purpose of non-destructively separating the battery cell is achieved, the cutter is prevented from damaging a shell of the battery cell, and the technical problems that the yield of manual disassemblyis low, and the manual disassembly is not suitable for large-scale disassembly of batteries are solved.

Owner:珠海中力新能源科技有限公司

Sealing device for steel ball conveying and press-in of lithium ionic cell

ActiveCN101038956APrecise deliveryPrevent liquid leakageFinal product manufactureSmall-sized cells cases/jacketsInjection portEngineering

The invention relates to a steel ball transferring pressing seal device for lithium battery, which includes an upper model board and a lower model board which are oppositely disposed and between which a sliding board provided with ball transferring hole is arranged in parallel; the upper model board is provided a ball storage cavity for transferring steel ball which is aslant opened from up to down; one side of the bottom face of the lower model board is provided with a cavity for battery positioning and opened upwards, opposite to which a steel ball inducing hole which vertically drills through the lower board; and opposite to the steel ball inducing hole of the lower board, a pin hammer inducing hole is vertically arranged on the upper model board in coaxial, within which a pin hammer is disposed. In application, the steel ball aslant slides form the ball storage cavity into the transferring hole of the sliding board, and the sliding board drives the steel ball forward to input the same into the steel inducing hole, and then, the steel ball is pressed into a battery injection port by the pin hammer vertical motion via the steel ball inducing hole thereby completing the seal for battery cover. The device is not only suitable for the seal in normal condition, but is also suitable for vacuum seal; and it can automatically transfer and supply the steel balls one by one, accurately position, and has remarkable effect.

Owner:TIANJIN JUYUAN NEW ENERGY TECH CO LTD

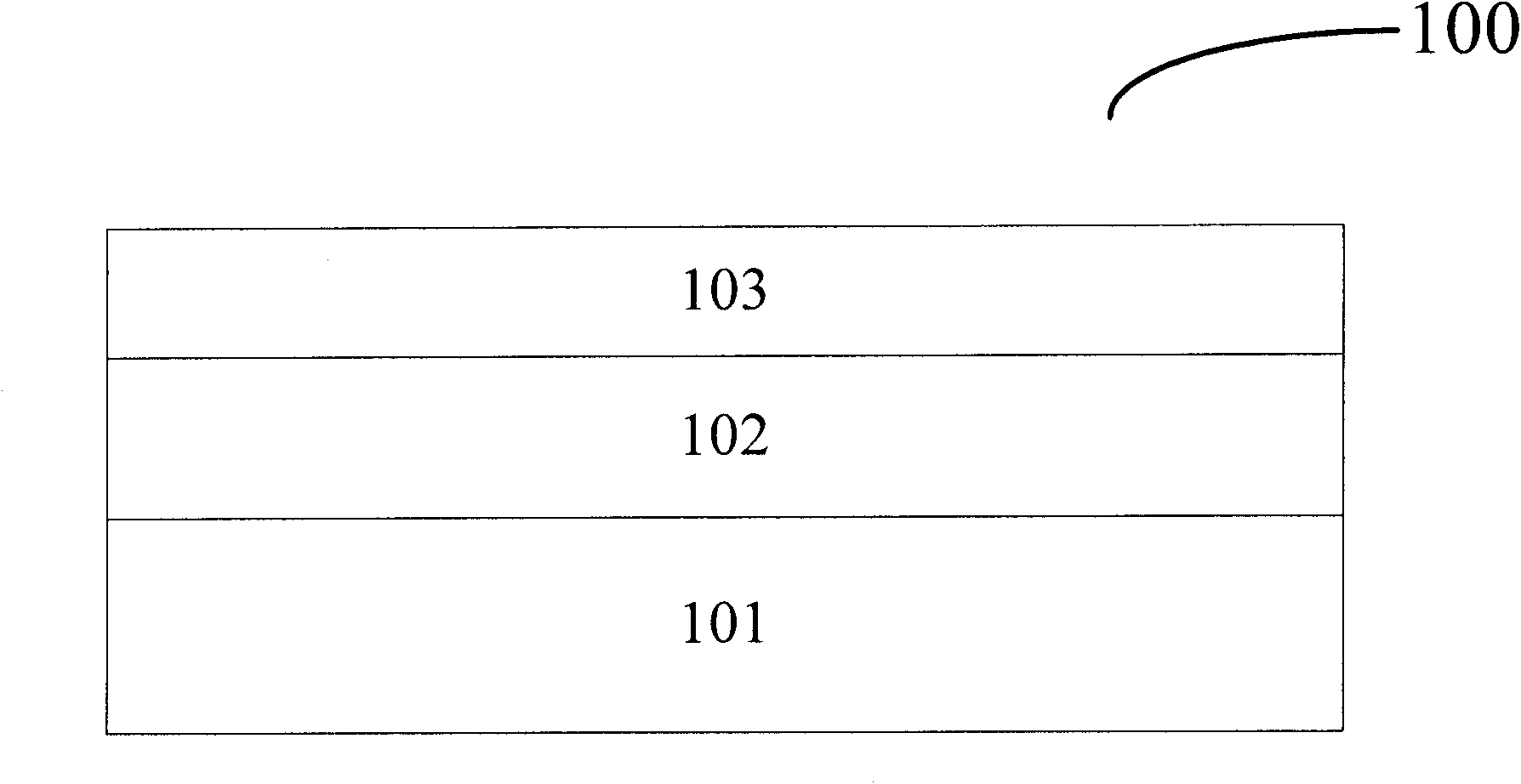

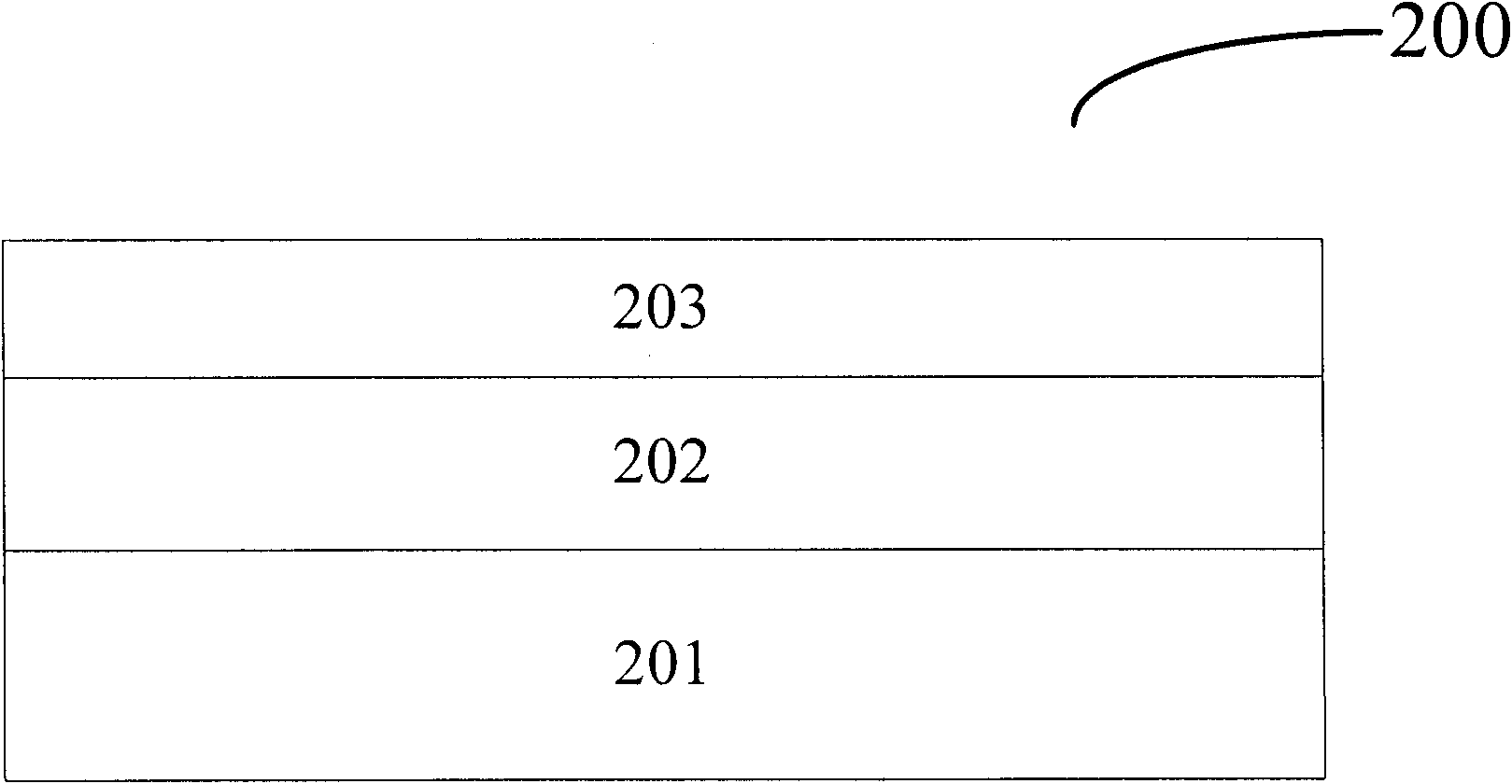

Semiconductor structure and manufacturing method thereof

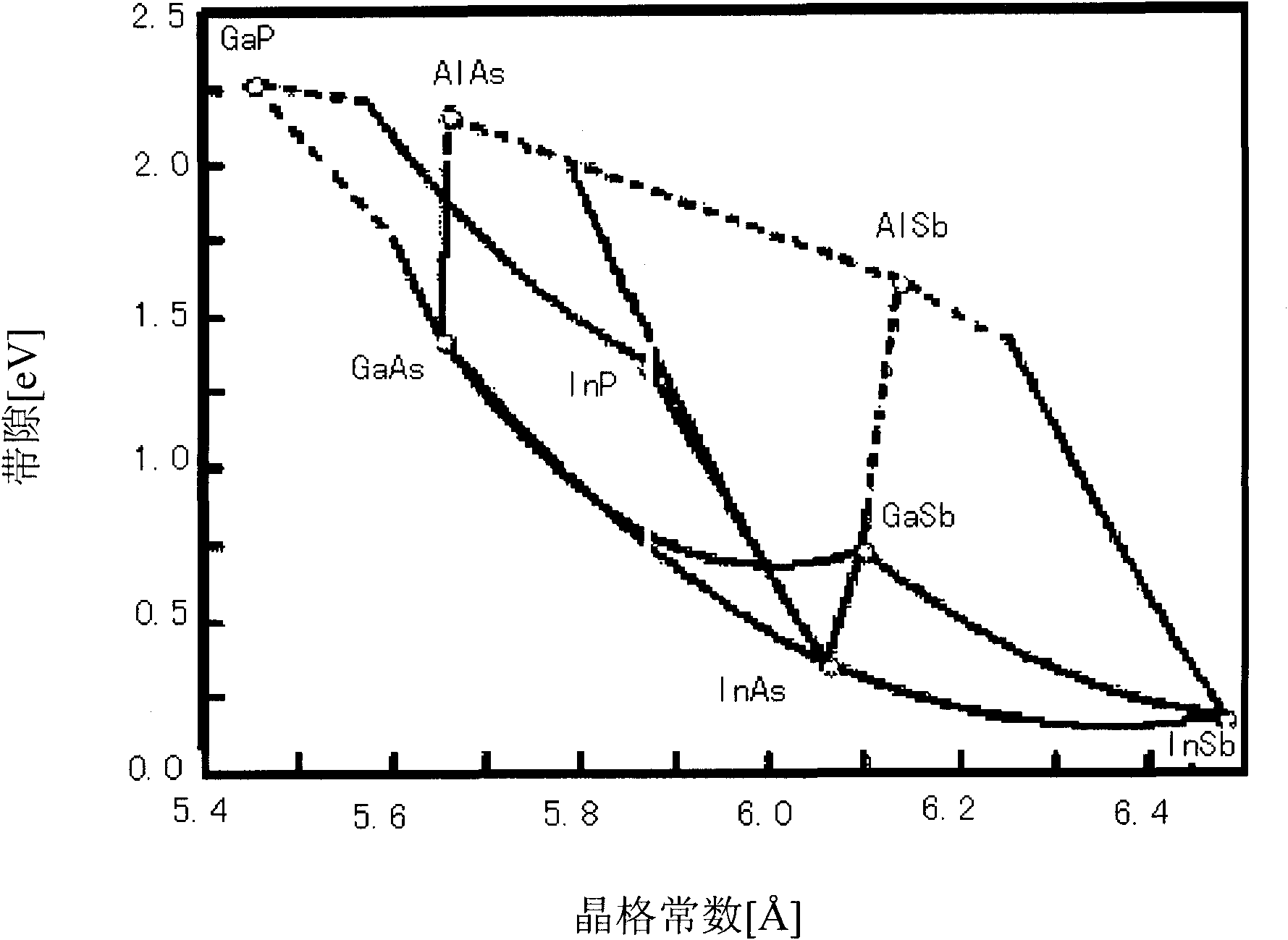

InactiveCN102214562ASuppression of short channel effectsSolve the requestSemiconductor/solid-state device manufacturingSemiconductor structureWide band

The invention provides a semiconductor structure and a manufacturing method thereof, relating to the field of semiconductor manufacturing. The semiconductor structure comprises a silicon substrate, a wide band gap semiconductor layer formed on the silicon substrate and a silicon layer formed on the wide band gap semiconductor layer. The method comprises the steps of growing the wide band gap semiconductor layer on the silicon substrate and growing the silicon layer on the wide band gap semiconductor layer. The embodiment of the invention can be applied to manufacturing of semiconductor devices.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Automatic assembling equipment for connector

PendingCN114421254ARealize the assemblyRealize automatic assemblyContact member assembly/disassemblyClassical mechanicsStructural engineering

Owner:WEIFANG LOKOMO PRECISION IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com