Mao bamboo continuous-flattening processing method and equipment

A technology of processing equipment and processing methods, which is applied in wood processing appliances, manufacturing tools, wood compression, etc., can solve the problems of high price of bamboo products, poor wettability of water and adhesive, and poor wettability of water and adhesive. , to achieve the effect of improving technological content and product added value, reducing process complexity and broad development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

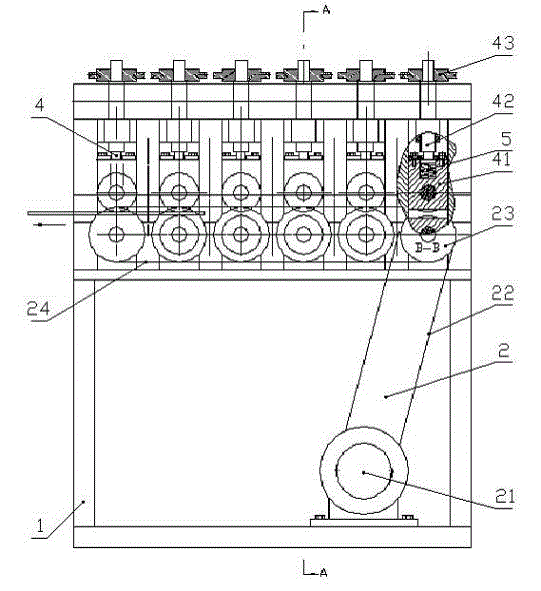

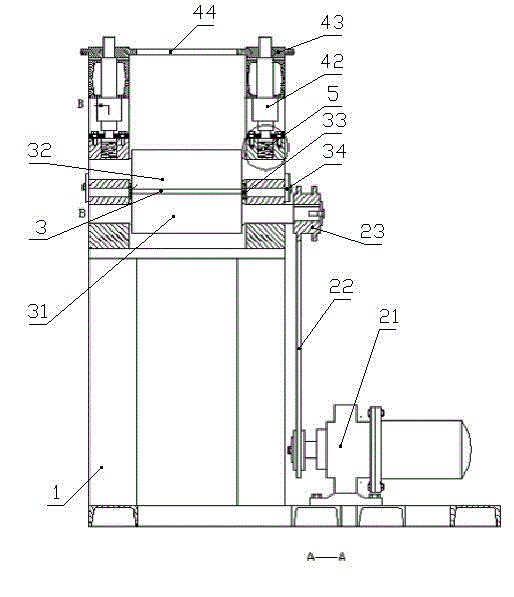

[0028] The present invention will be further explained below in conjunction with the drawings and embodiments.

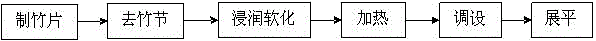

[0029] reference figure 1 , A method for continuous flattening of moso bamboo, including the following steps:

[0030] (1) Making bamboo slices: After cutting the fresh moso bamboo, use a smashing machine to break the bamboo pieces into 5cm, 8cm or 10cm end arc lengths of moso bamboo slices, and stack them according to the arc length;

[0031] (2) Remove the bamboo section: first remove the outer section of the moso bamboo sheet, then remove the inner section of the moso bamboo sheet, and finally, set a shallow diagonal groove on the inner wall of the moso bamboo sheet. (3) Wetting and softening: Classify and bundle the bamboo slices with different end arc lengths, put them in the pool, fill with water, add weight to the bamboo slice bundle to make the bamboo slice bundle completely submerged in the water, and add bamboo fiber to the water Softener

[0032] (4) Heating: Pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Arc length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com