Cleaning process of winding plating polycrystalline silicon

A polysilicon, wrapping technology, applied in sustainable manufacturing/processing, electrical components, climate sustainability, etc., can solve the problems of low battery conversion efficiency and low yield, and achieve lower production costs, good application prospects, and improved conversion. The effect of efficiency and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

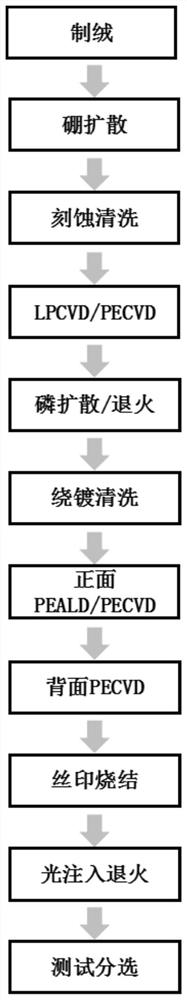

[0053] A kind of cleaning process that is applicable to TOPCon cell wrapping polysilicon, specifically: the preparation process of TOPCon cell based on LPCVD route (such as figure 1 shown) exists around the polycrystalline silicon to clean, comprising the following steps:

[0054] (1) Texture the front and back of the silicon wafer.

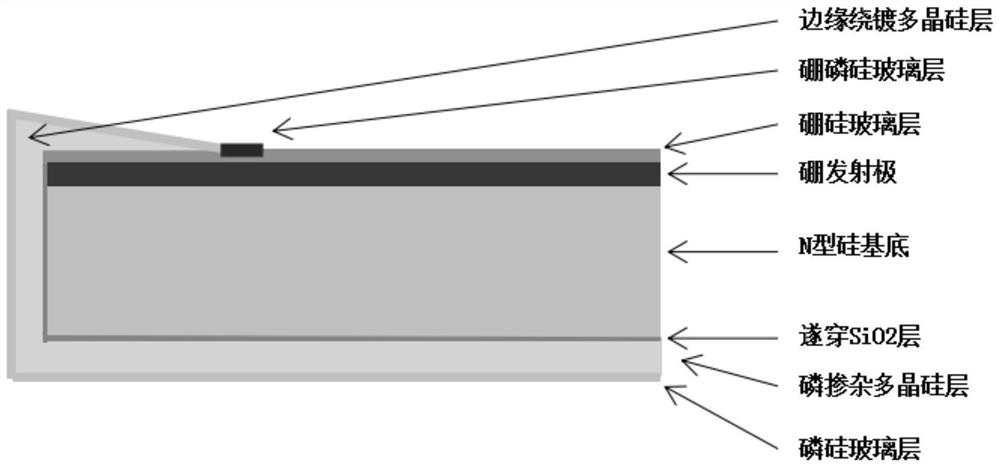

[0055] (2) Carry out boron diffusion on the front side of the silicon wafer after texturing, and form a p+ emitter and a BSG layer (borosilicate glass layer) on the front side of the silicon wafer. The thickness of the BSG layer is 100 nm.

[0056] (3) Etching and cleaning the boron-diffused silicon wafer to remove the BSG layer and the boron emitter on the edge and back.

[0057] (4) Using single-slot double-insertion method, using LPCVD technology to sequentially grow tunnel oxide layer and polysilicon layer on the back of the silicon wafer, and perform phosphorus diffusion doping on the back polysilicon layer to form a PSG layer (phosphosilic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com