Integrated projection-type capacitive touch screen and manufacturing method thereof

A technology of capacitive touch screen and manufacturing method, which is applied to the input/output process of electrical digital data processing, instruments, and data processing, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

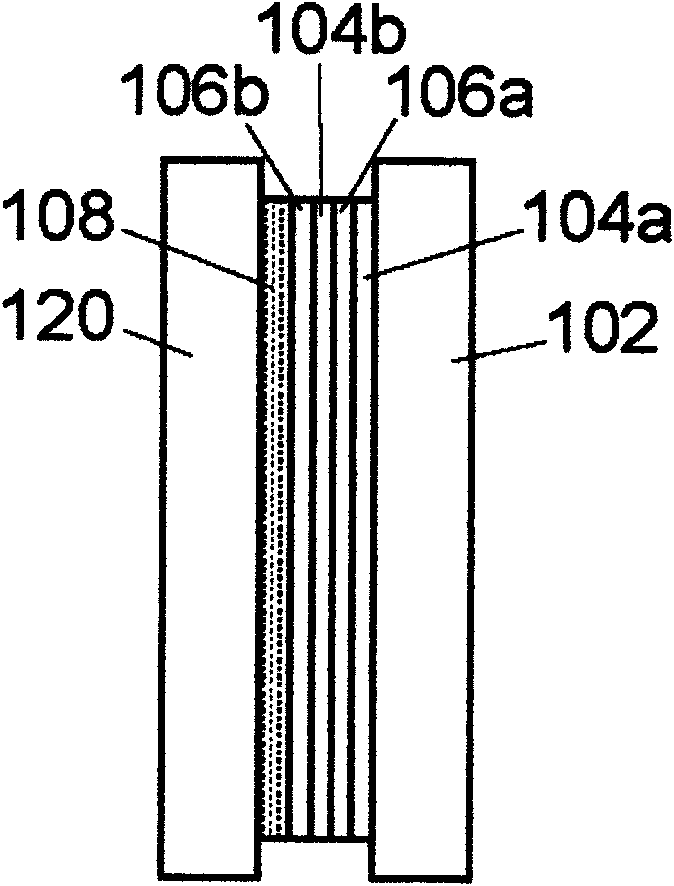

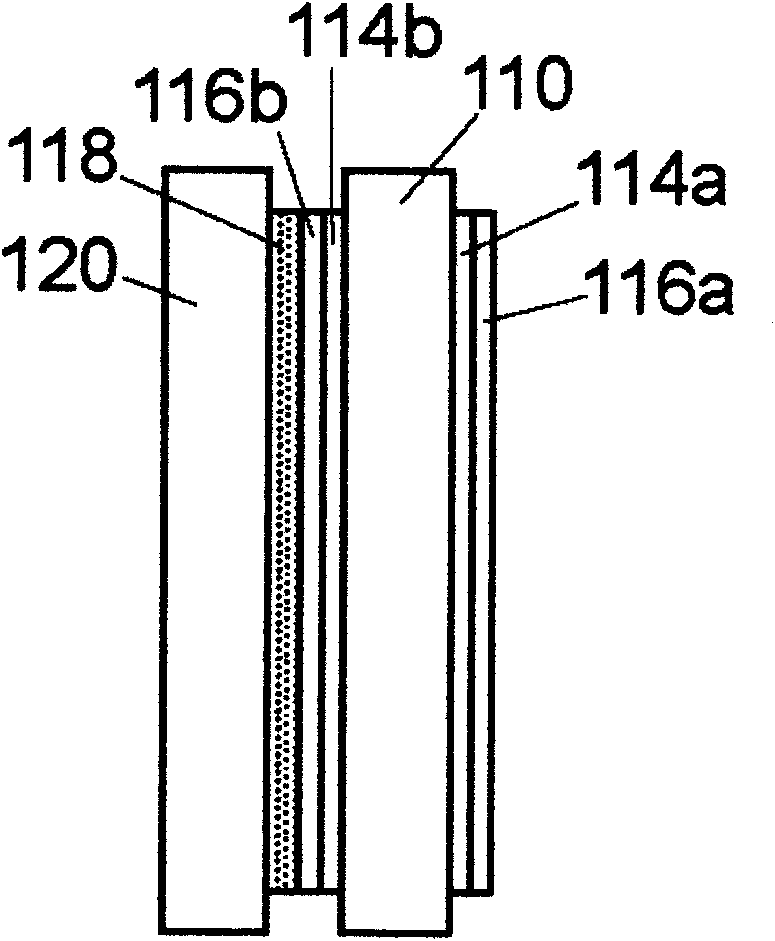

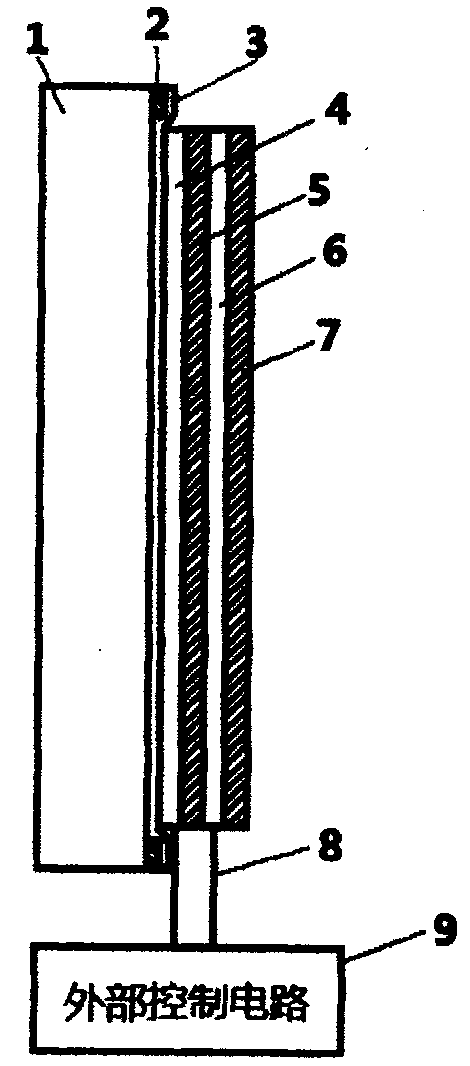

[0043] Such as image 3 The integrated projected capacitive touch screen shown in ~6 is special in that only one substrate 1 is used, and a color coating 2 is provided on the non-visible area of the substrate 1, and a color coating 2 is provided on the substrate. 2 is provided with a bottoming insulating film 3 on the entire surface, and a first electrode pattern 4 is provided on the bottoming insulating film 3; a dielectric insulating film 5 is provided on the first electrode pattern, and a dielectric insulating film 5 is provided on the electrolyte edge film. The second electrode pattern 6, and the coverage of the electrolyte insulating film 5 does not include the joint terminal of the first electrode pattern 4; the second electrode pattern 6 is provided with a protective insulating film 7, and the electrical protective insulating film 7 The coverage range does not include the bonding terminals on the edges of the first electrode pattern 4 and the second electrode pattern ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com