Processing method of round bamboo high-temperature hardening, softening and flattening

A processing method and round bamboo technology are applied in the processing field of high temperature quenching, softening and flattening of round bamboo, and can solve the problems of high price of bamboo products, poor wettability of water and adhesive, and poor wettability of water and adhesive. , to achieve the effect of improving technological content and product added value, reducing process complexity and broad development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

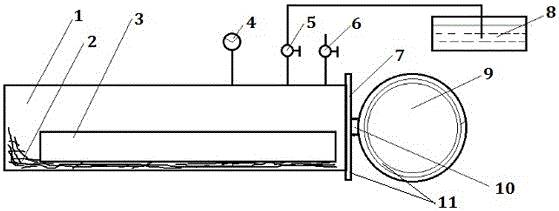

[0029] Such as Figure 1-2 Shown, a kind of processing method of high-temperature quenching softening and flattening of round bamboo comprises the following steps:

[0030] Step 1: Select fresh moso bamboo, remove the sundries on the bamboo stem, cut it into 0.5-2.6m round bamboo sections, and set aside;

[0031] Step 2: send the truncated round bamboo sections into the machining process for removing outer joints, and remove all the raised outer joints of the round bamboo sections;

[0032] Step 3: Send the round bamboo section from which the outer section has been removed to the machining process to remove all the inner sections of the round bamboo section;

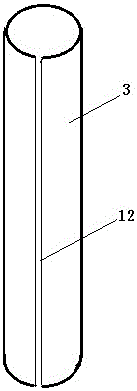

[0033] Step 4: Send the round bamboo section from which the inner section has been removed to the slitting saw, and open a through sawing path 12 along the length direction of the round bamboo section on the side of the round bamboo section for standby;

[0034] Step 5: Put the round bamboo section sawn on the side int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com