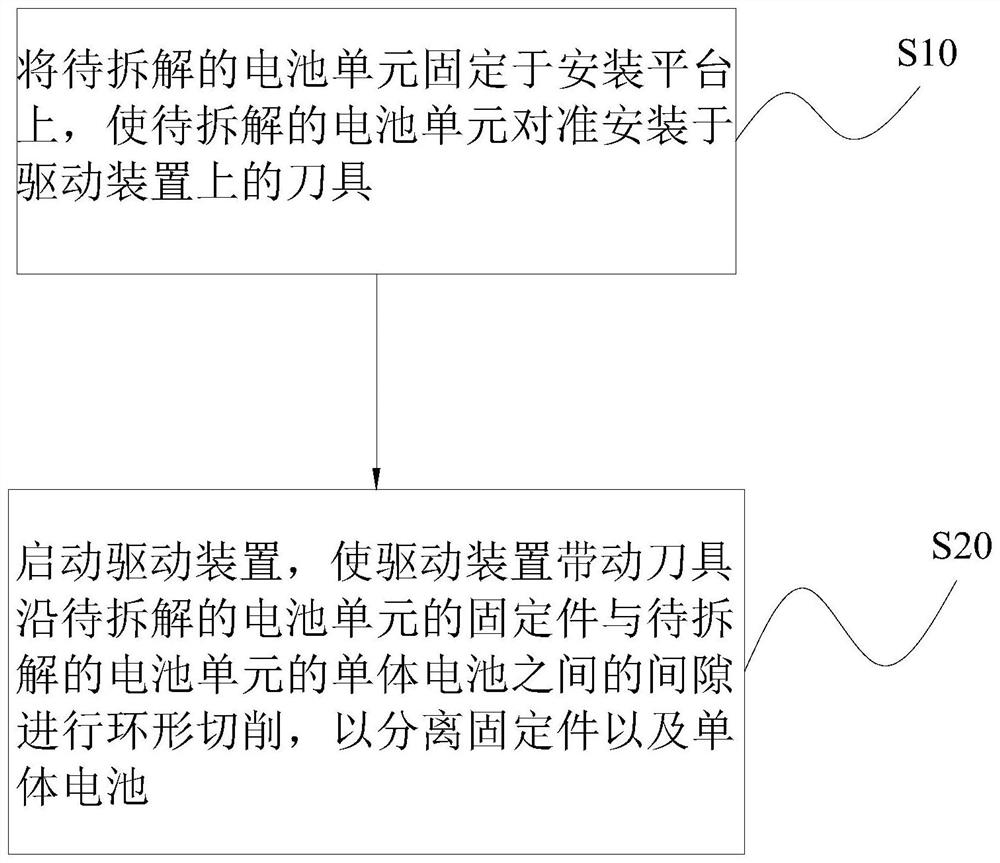

Method for non-destructively disassembling battery cell and cutter used by method

A single battery and tool technology, which is applied in the field of non-destructive disassembly of single batteries, can solve the problems of low yield rate and is not suitable for large-scale disassembly of battery cells, and achieves the effect of solving low yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

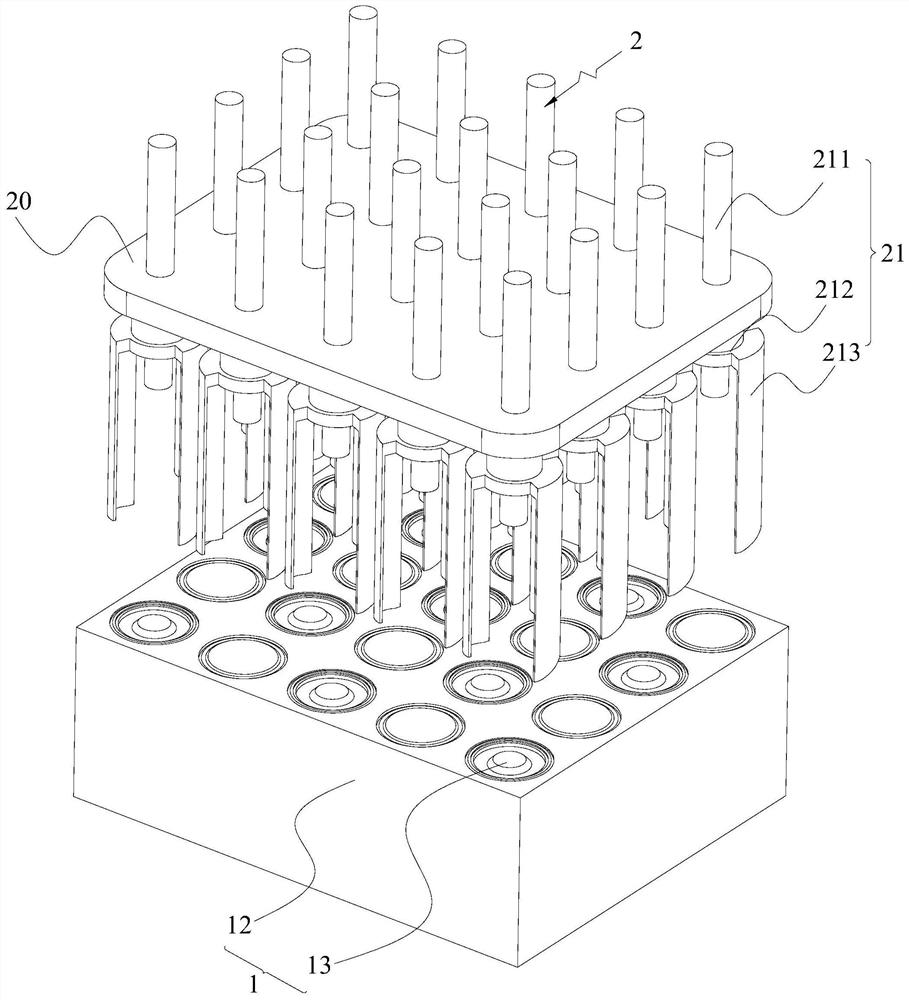

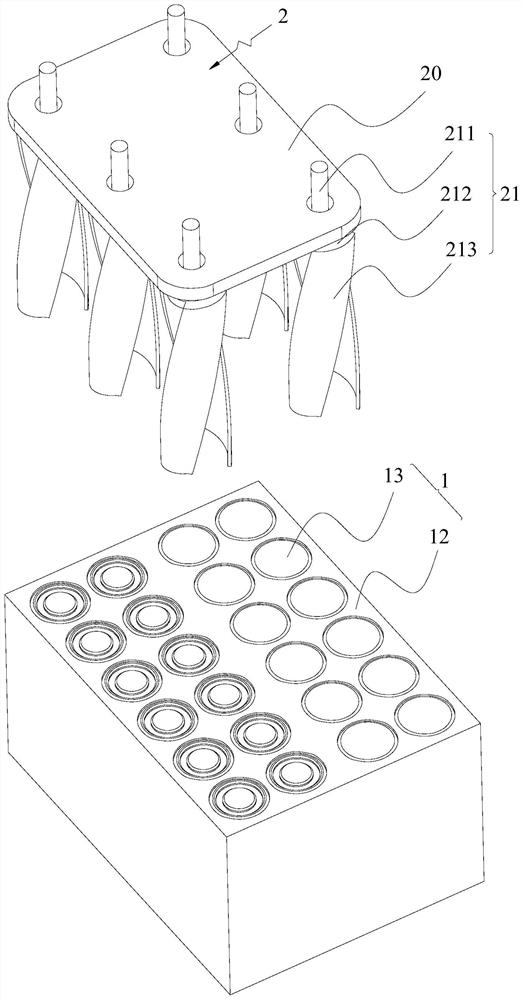

[0063] Such as figure 2 and Figure 6 As shown, the 20s1p 32700 battery pack is fixed by plastic frames at both ends and polyurethane foam inside. The size of the single battery 13 is 32mm in diameter and 70mm in height. The distance between the axes of two adjacent single cells 13 is 40mm. Choose a two-leaf cutter unit 21 with an inner diameter of 33mm, a wall thickness of 1mm, and an inner length of 75mm. The axial center distance between two adjacent cutter units is 40mm, matching the arrangement of the single batteries 13, and combining a 4*5 array The battery pack is disassembled, that is, there are 4 cutter units 21 distributed along the width direction of the mounting plate 20, and 5 cutter units 21 are distributed along the length direction of the mounting plate 20. One working cycle of the cutter unit 21 array can complete all 20 Disassembly of a single battery 13.

Embodiment 2

[0065] Such as image 3 and Figure 7 As shown, a 2s12p 18650 battery module is filled and fixed with solid glue, and the size of the single battery 13 is 18mm in diameter and 65mm in height. The axial centers of the single cells 13 are not all the same, the axial center distance of two adjacent single cells 13 along the length direction of the fixing member 12 is 20 mm, and the axial center distance of two adjacent single cells 13 in the width direction is 25 mm. Since the axial center distances of two adjacent single cells 13 in the length direction and the width direction are relatively small, separate positions are used for simultaneous operation. A spiral two-leaf cutter unit 21 with an inner diameter of 19 mm, a wall thickness of 1 mm, and an inner length of 71 mm is selected. According to the arrangement of the single batteries 13, 6 groups of cutter units 21 are arranged in alternate positions. There are three cutter units 21 distributed in the length direction, and t...

Embodiment 3

[0067] Such as Figure 4 , Figure 8 and Figure 9 As shown, for a 4s5p 32139 battery module fixed by resin brackets at both ends, the size of the single battery 13 is 32mm in diameter and 139mm in height. The distance between the axes of two adjacent single cells 13 is 40mm. 8 straight blade cutters 2 with an inner diameter of 34 mm and a wall thickness of 1 mm are selected. Since the fixing parts 12 are located at the two ends of the single battery 13, there is no fixing part 12 in the middle, and the length of the single battery 13 is long, the inner length of the cutter 2 is selected to be 25 mm, and the two ends of the single battery 13 are cut simultaneously. In this way, the disassembly of all 20 single cells 13 of one battery module can be completed in one working cycle. In this embodiment, the distance between two adjacent cutter units 21 is 40 mm. Since the length of the single battery 13 is relatively long, if the cutter unit 21 with a relatively long length is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com