Spinning process for improving cohesive force between cotton-wool blended yarn fibers

A technology of blending yarn and cotton fiber, applied in ultrasonic/sonic fiber processing, yarn, textile and papermaking, etc., can solve the problem of poor cohesion between fibers, improve the friction coefficient of fiber surface, enhance mechanical properties, and improve cohesion. combined effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment provides a spinning process for improving the cohesion between fibers of cotton-wool blended yarn and the obtained cotton-wool blended yarn. The spinning process provided comprises the following steps:

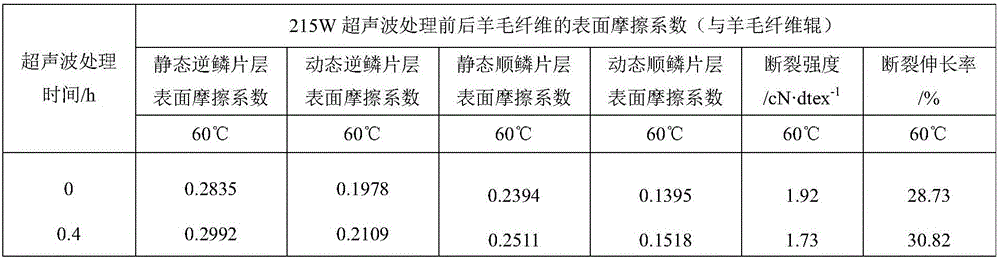

[0039] S1. Put the wool fiber in an environment with a temperature of 60°C and an ultrasonic power of 215W for 0.40h; place the cotton fiber in an environment with a temperature of 70°C and an ultrasonic power of 240W for 0.65h; the corresponding test performance As shown in Table 1 and Table 2 below:

[0040] Table 1

[0041]

[0042] Table 2

[0043]

[0044] S2. Use the FA002 type automatic plucking machine to pluck the wool fiber after the ultrasonic treatment in the step S1; and use the A035A cotton blender to mix the wool fiber after the pluck; and then use the FA106B cotton opener to use Carding drum, control the output speed to 480rpm, and open the cotton; adopt FA141 single beater lapping machine, use card pin beater, control the fixed a...

Embodiment 2

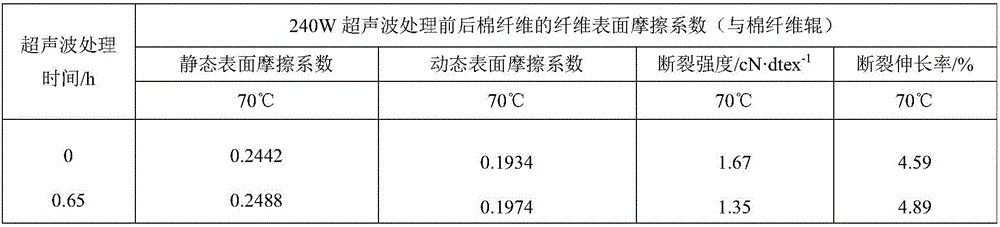

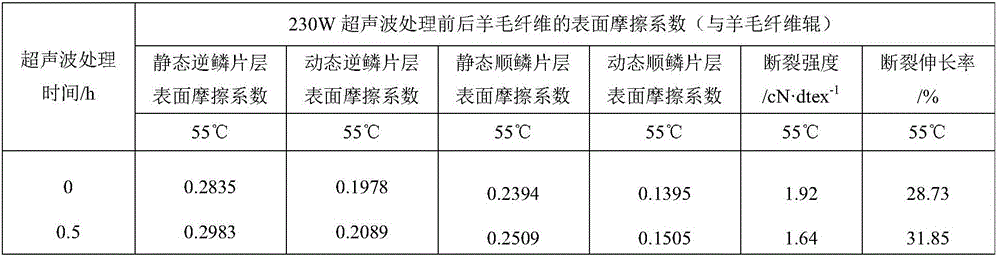

[0052] This embodiment provides a spinning process for improving the interfiber cohesion of cotton-wool blended yarn and the obtained cotton-wool blended yarn. The spinning process provided is in accordance with the spinning process in Example 1, only step S1 The ultrasonic treatment parameters of the wool fiber are set as follows: ultrasonic power is 230W, the temperature is 55°C, and the time is 0.5h; the ultrasonic treatment parameters of the cotton fiber in step S1 are set as: ultrasonic power is 230W, the temperature is 80°C, and the time is 0.8h; the corresponding test performance is shown in Table 3 and Table 4 below:

[0053] table 3

[0054]

[0055] Table 4

[0056]

[0057] Finally, a cotton-wool blended yarn with a fineness of 30.0tex and a twist of 65.0 twist / 10cm was prepared.

[0058] After testing, the breaking strength of the cotton-wool blended yarn prepared in this example is 311.7N, and the breaking elongation is 5.05%.

Embodiment 3

[0060] This embodiment provides a spinning process for improving the interfiber cohesion of cotton-wool blended yarn and the obtained cotton-wool blended yarn. The spinning process provided is in accordance with the spinning process in Example 1, only step S1 The ultrasonic processing parameters of the wool fiber are set as follows: ultrasonic power is 200W, the temperature is 65°C, and the time is 0.5h; the ultrasonic treatment of the cotton fiber in step S1 is: ultrasonic power is 250W, the temperature is 80°C, and the time is 0.5h ; The corresponding test performance is shown in Table 5 and Table 6 below:

[0061] table 5

[0062]

[0063] Table 6

[0064]

[0065] The final prepared cotton-wool blended yarn has a fineness of 29.5tex and a twist of 60.0 twist / 10cm.

[0066] After testing, the breaking strength of the cotton-wool blended yarn prepared in this example is 304.8N, and the breaking elongation is 5.24%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com