High-compression-resistance three-dimensional hollow composite floor and manufacturing method thereof

A composite floor and manufacturing method technology, applied in building structure, floor, building, etc., can solve the problems of reduced compressive strength of hollow composite materials, low compressive strength of hollow composite materials, and limited range of fleece densification, etc., to achieve Guaranteed interface strength, enhanced compressive performance, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

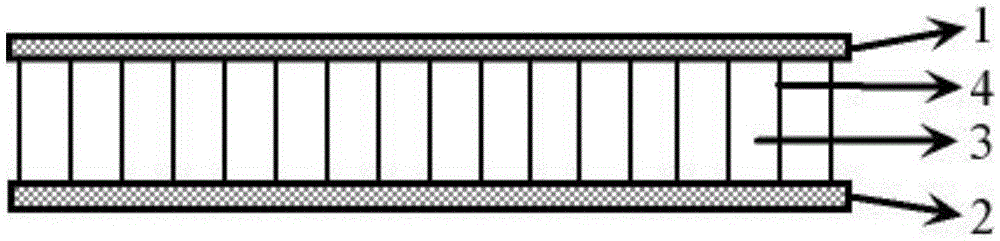

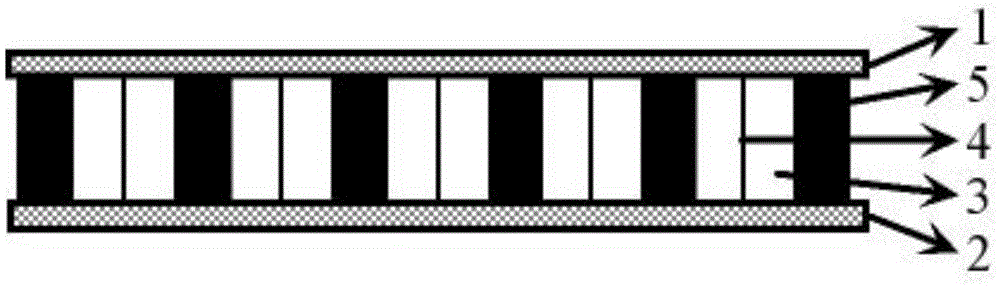

[0040] This embodiment provides a high-compression 3D hollow composite floor and its manufacturing method. The high-compression 3D hollow composite floor includes a 3D hollow fabric that constitutes the overall frame of the 3D hollow composite floor and is arranged in the void of the 3D hollow fabric pile structure layer. The middle reinforcing rib; the structural size of the middle reinforcing rib is consistent with the structural size of the gap of the 3D hollow fabric fleece structure layer.

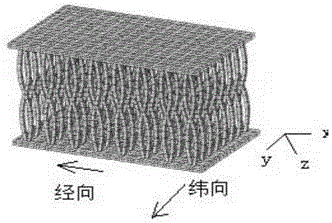

[0041] The 3D hollow fabric in this embodiment 1 adopts 18mm thick 3D non-alkali glass fiber hollow fabric, and this 3D non-alkali glass fiber hollow fabric is a prefabricated body of reinforcing material, which is used as the overall frame of the high-pressure-resistant 3D hollow composite floor; the middle reinforcement The rib is made of solid glass fiber composite material; and epoxy resin is used as the matrix material. Among them, the structural effect diagram of 3D alkali-free ...

Embodiment 2

[0056] It is basically the same as in Example 1, except that the reinforcing material prefabricated body is 20 mm 3D carbon fiber hollow fabric, the middle rib material is carbon fiber composite material and the number of ribs is 32.

[0057] The manufacturing method of the high-compression 3D hollow composite floor in Example 2, the steps are as follows:

[0058] 1) The cutting size is length (1m)×width (1m)×height (20) 3D carbon fiber hollow fabric, numbered D, according to the void size of the pile structure layer in the above 3D carbon fiber hollow fabric, prepare length (1m)×width (4mm) × high (20mm) carbon fiber composite middle rib.

[0059] 2) Surface grinding, deburring, and chamfering of the intermediate ribs in step 1, and cleaning them with acetone; pre-embed the surface-treated intermediate ribs in the voids of the 3D carbon fiber hollow fabric fleece structure layer; Among them, the number of middle ribs is 32, and the middle ribs are evenly distributed in the g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com