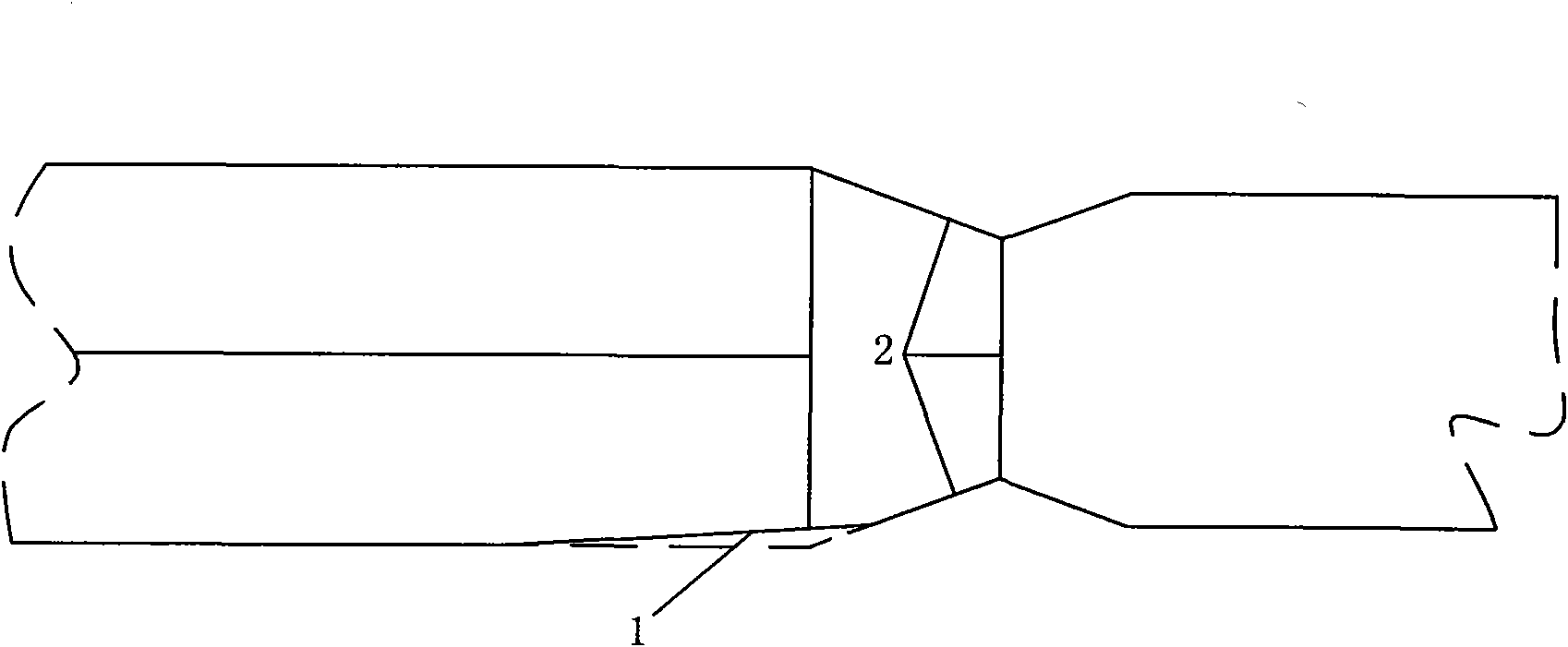

Linear groove and transition groove cutter device

A technology of bevel cutting and straight line transition, which is applied in the direction of auxiliary devices, welding/cutting auxiliary equipment, auxiliary welding equipment, etc., can solve the problems of inability to perform transition bevel cutting, etc., to improve cutting production efficiency, control thermal deformation, structure compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

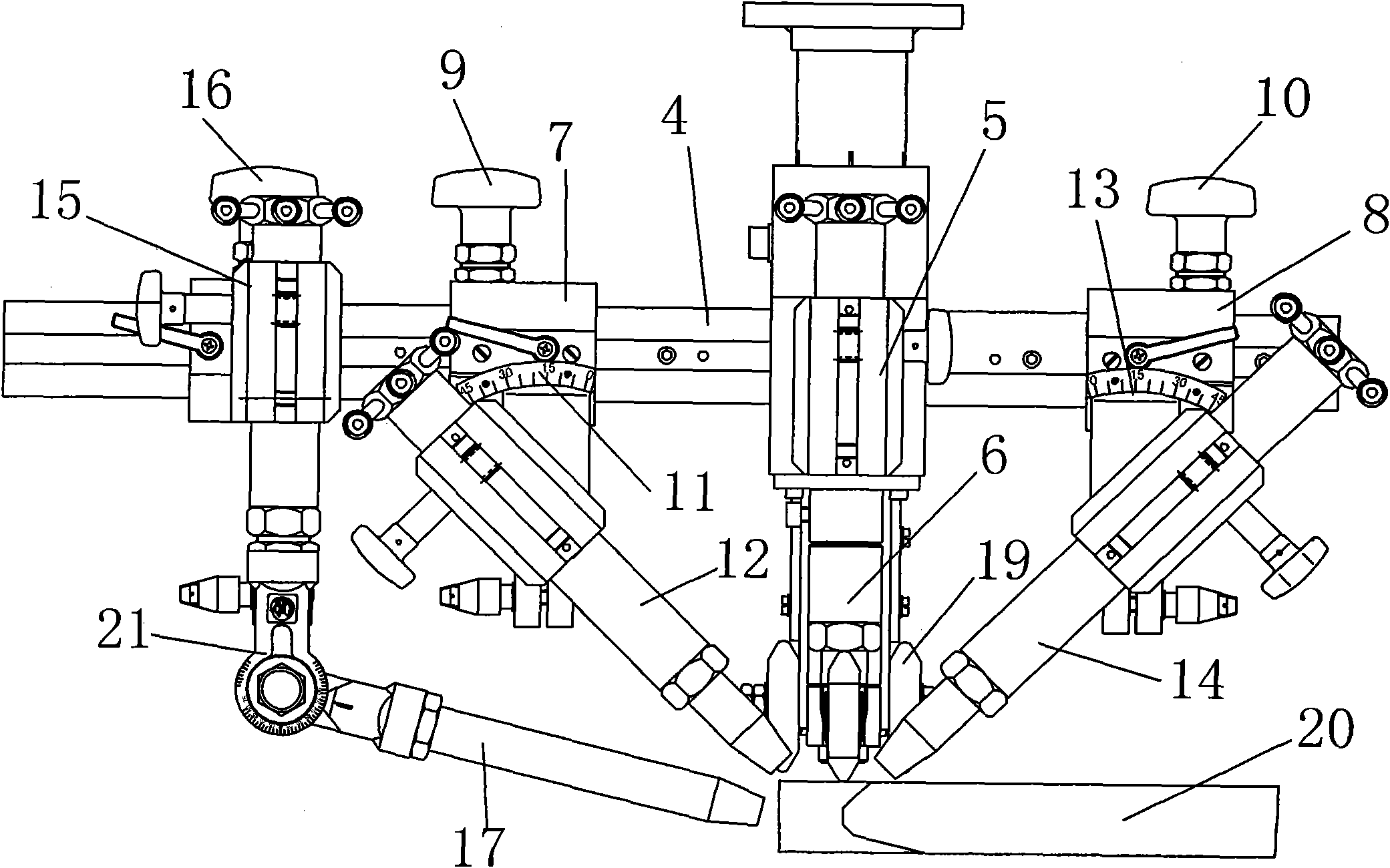

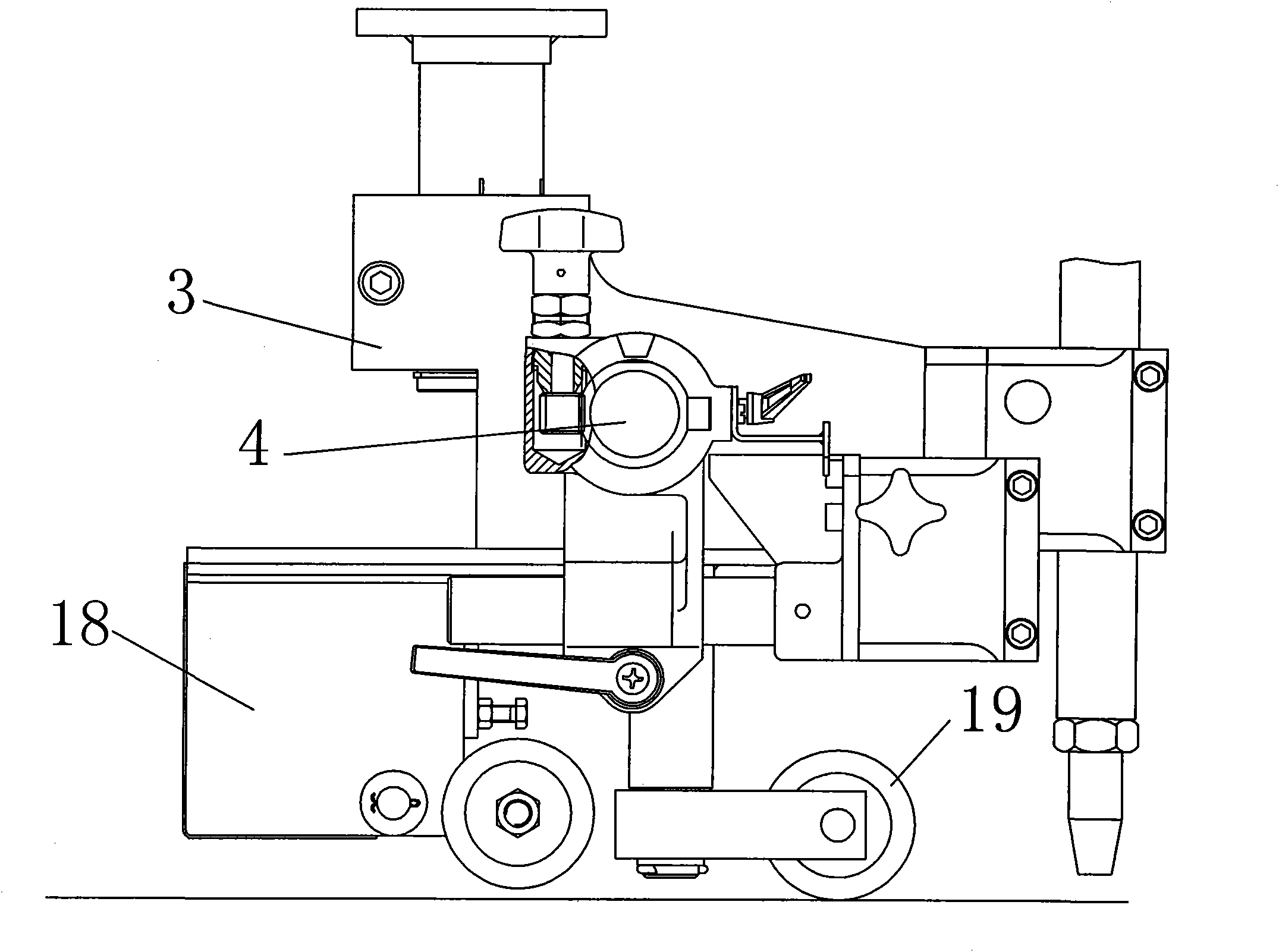

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0018] A linear transition bevel cutting device, comprising a frame 3, a rack bar 4 is provided on the frame 3, a central cutting torch connecting frame 5 is fixed on the rack bar 4, and the center A central cutting torch 6 is arranged on the cutting torch connecting frame 5;

[0019] Both sides of the central cutting torch connecting frame 5 have a left mobile body 7 and a right mobile body 8 respectively, the left mobile body 7 is connected with the left hand wheel 9, and the left hand wheel 8 is connected with the rack bar 4 meshing; the right moving body 8 is connected with the right hand wheel 10, and the right hand wheel 10 is meshed with the rack bar 4;

[0020] The left moving body 7 is provided with a left cutting torch holder 11, and the left cutting torch holder 11 is provided with a left cutting torch 12; the right moving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com