Method for processing transformer pulling plate magnet isolation tank

A processing method and technology of magnetic isolation grooves, which are applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problems that the magnetic isolation grooves are easily cut obliquely or even cut off, and affect the quality of the pull plate, so as to avoid the need for re-calibration. The effect of low process, small investment and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

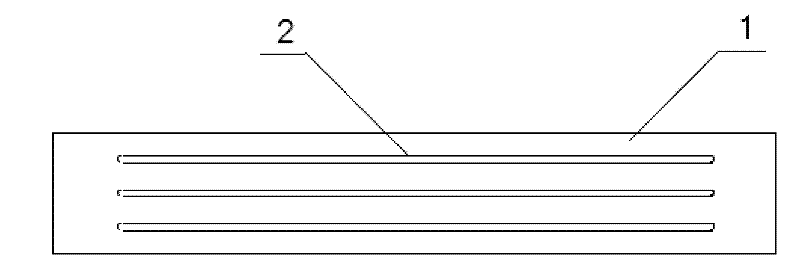

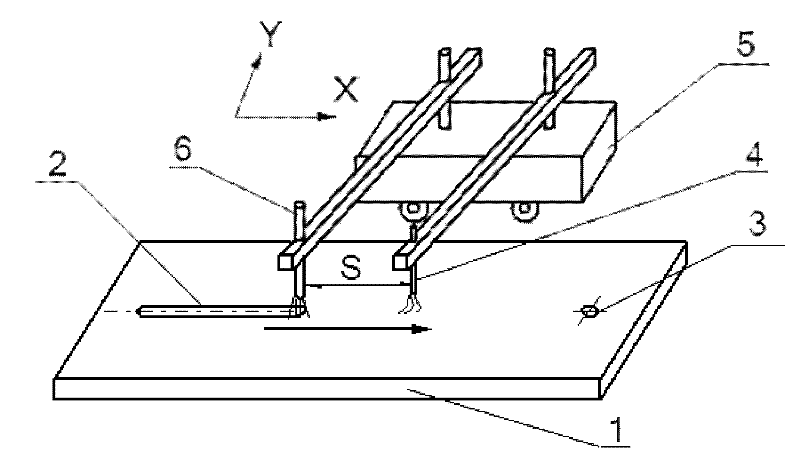

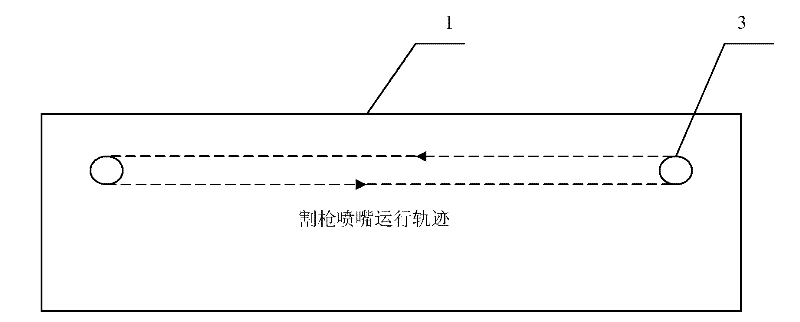

[0018] Such as figure 2 , image 3 As shown, a processing method of the magnetic isolation groove of the transformer pull plate:

[0019] In the first step, process holes 3 with a diameter of Φ10 are respectively drilled at both ends of the length of the drawing plate body 1 in the X direction.

[0020] In the second step, one end of the process hole is aligned with the nozzle of a flame torch 6 along the inside of the Y direction of the pull plate body length, and there is a cooling water pipe 4 on the same line as the flame torch 6 along the X direction; 6. The cooling water pipe 4 is connected to the moving trolley 5 on the side of the Y direction of the width of the drawing plate body 1 through two mutually parallel arms; the distance between the flame torch 6 and the cooling water pipe 4 is 50-200mm.

[0021] The third step is to turn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com