A Roots blower impeller

A Roots blower and impeller technology, which is applied in the direction of mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of uneven thermal deformation of the Roots blower impeller, and achieve the effect of small thermal deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

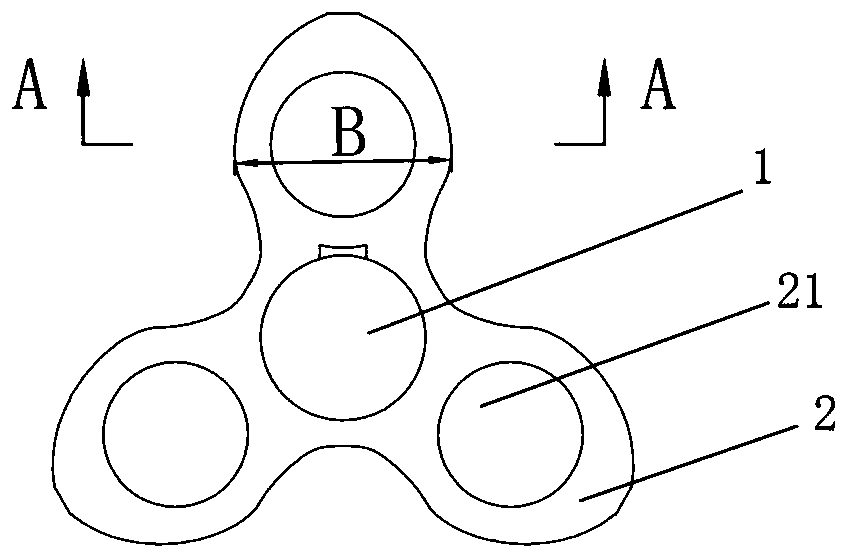

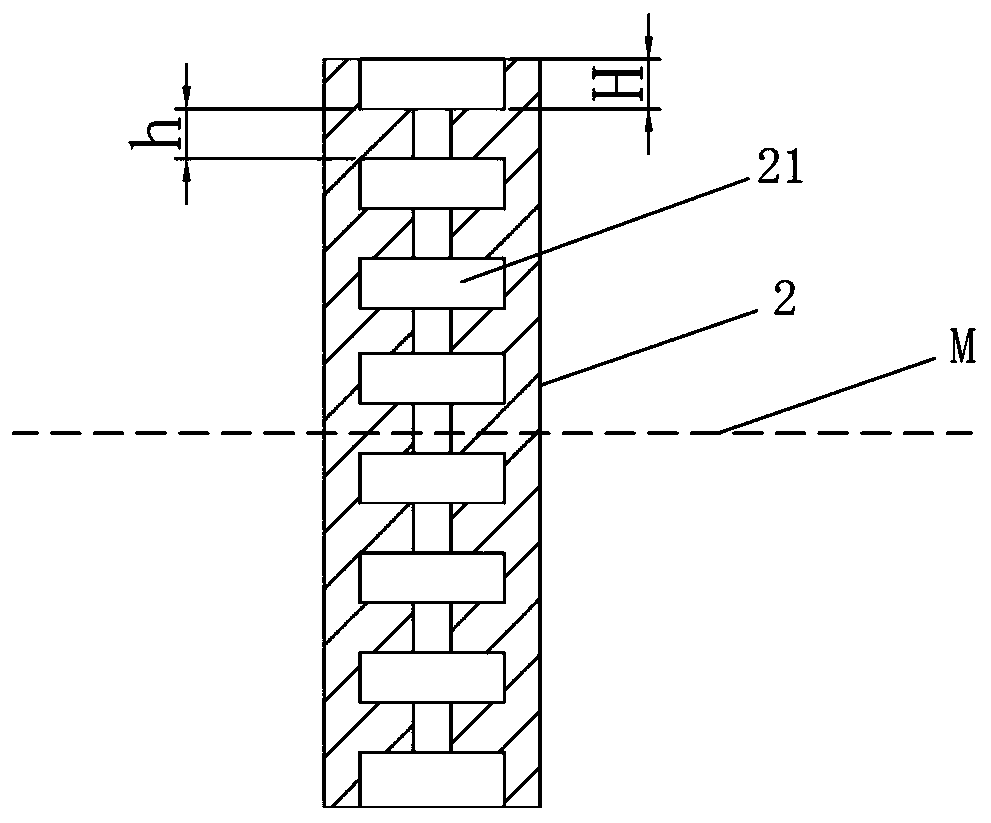

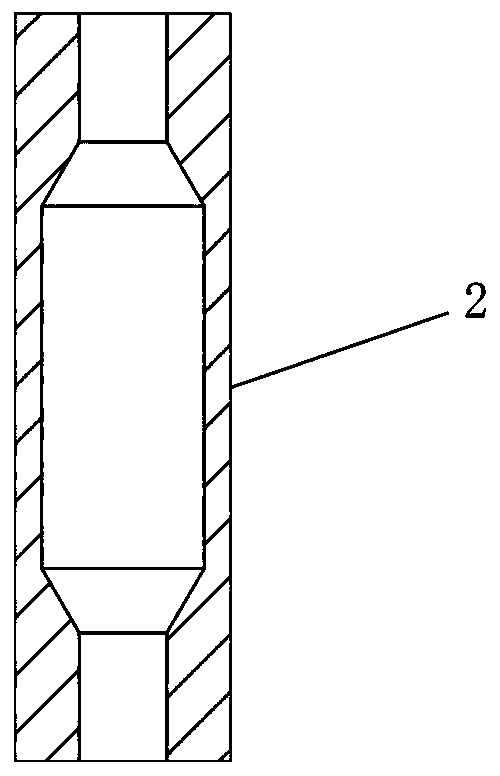

[0033] Such as figure 1 and figure 2 As shown, the Roots blower impeller of this embodiment has a center-symmetrical structure. The center of the Roots blower impeller is provided with an impeller shaft sleeve hole 1, and three impeller blades 2 are provided along the circumference of the impeller shaft sleeve hole 1. And each impeller blade 2 is provided with a balance hole 21, the balance hole 21 is a stepped cylindrical hole alternately stacked axially by a large-diameter cylindrical hole and a small-diameter cylindrical hole, and the axes of the large-diameter cylindrical hole and the small-diameter cylindrical hole coincide. The structure of the variable-section balance hole 21 adjusts the original uneven wall thickness of the impeller blade 2, so that the impeller can produce uniform thermal deformation, so as to control the wall thickness of the impeller blade 2 by adjusting the structure of the balance hole 21, and then The purpose of controlling the thermal deforma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com