Lead liquid dosing device and plate-casting machine

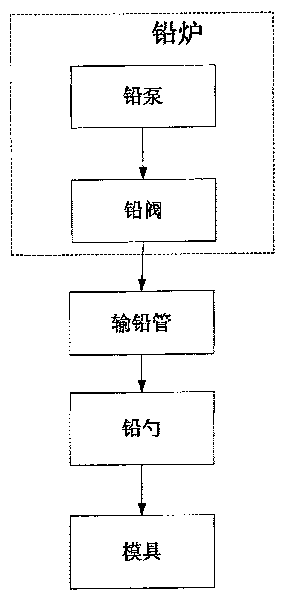

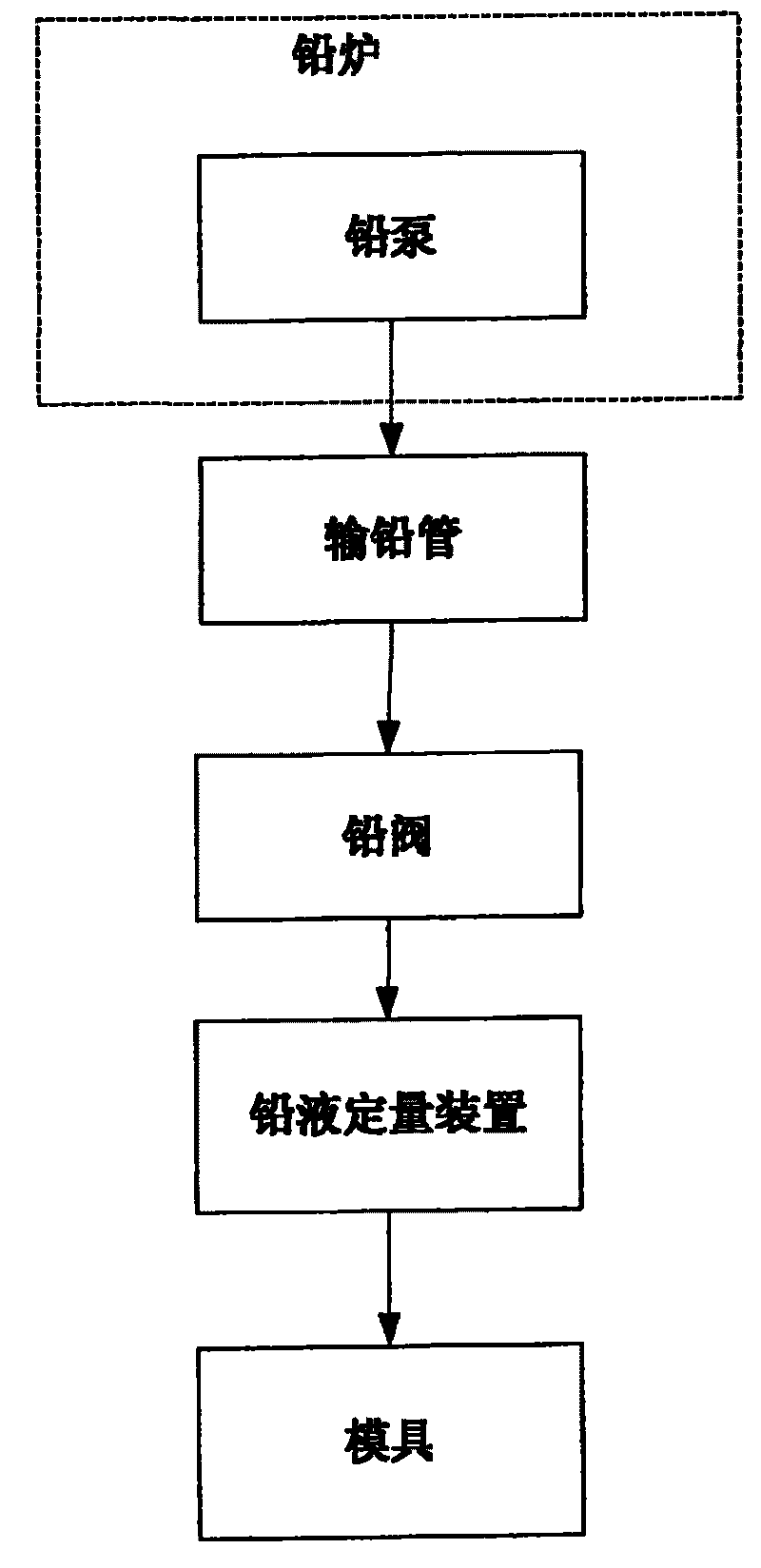

A quantitative device and liquid lead technology, which is applied to casting equipment, equipment for supplying molten metal, metal processing equipment, etc., can solve problems such as harsh working environment, affecting work efficiency, complex lead valve structure, etc., and achieves low maintenance cost, low lead The effect of accurate liquid quantification and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

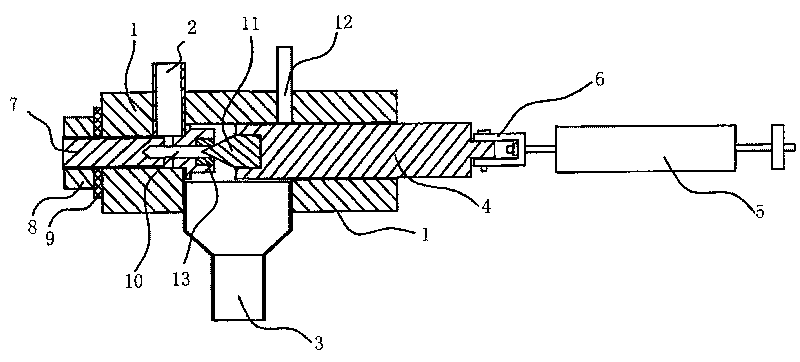

[0031] The lead liquid quantitative device of this specific embodiment is as figure 2 As shown, the housing 1 is included. The housing 1 is hollow, and the left part of the hollow part has a smaller diameter for accommodating the valve core 7; the right part has a larger diameter and is used for accommodating the valve stem 4. In addition, lead inlet 2 communicates with the position where the valve core 7 is accommodated at the left end; lead outlet 3 communicates with the position where the valve stem 4 is accommodated on the right.

[0032] The shape of the spool 7 is similar to that of a bolt, and includes two cylinders with different diameters. There is a section of external thread at one end of the small cylinder, which is used for fastening with the nut 8. One end of the large cylinder is provided with a notch, and the inser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com