Piezoresistance with alloy type temperature fuse

A temperature fuse, varistor technology, applied in varistor, varistor core, overvoltage protection resistors and other directions, can solve the problems of easy failure, complex structure, failure, etc. Quick response, easy installation and simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

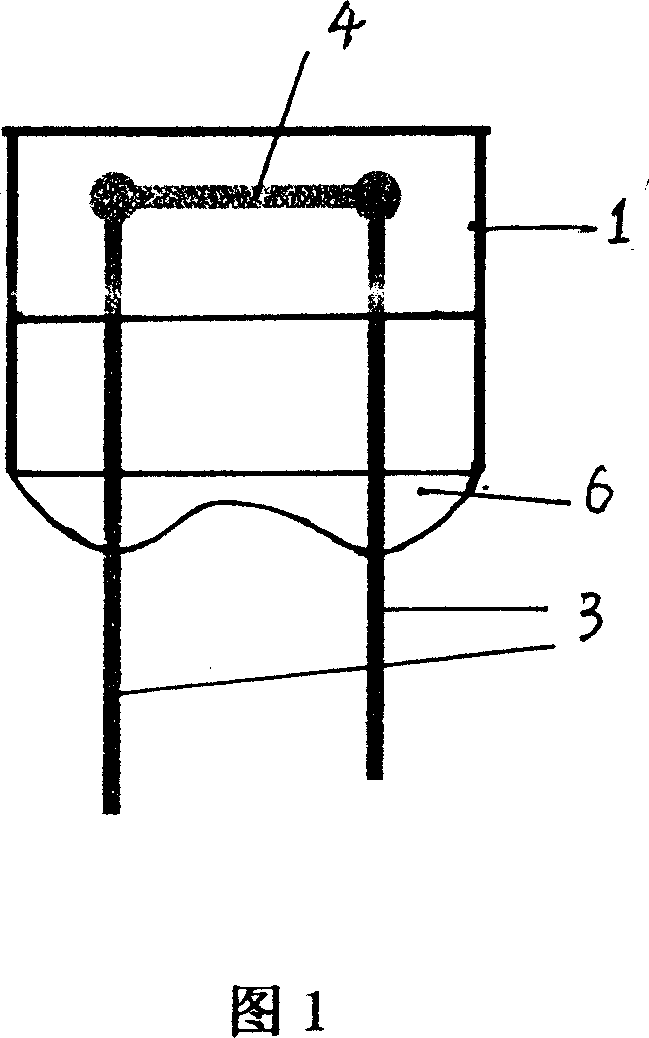

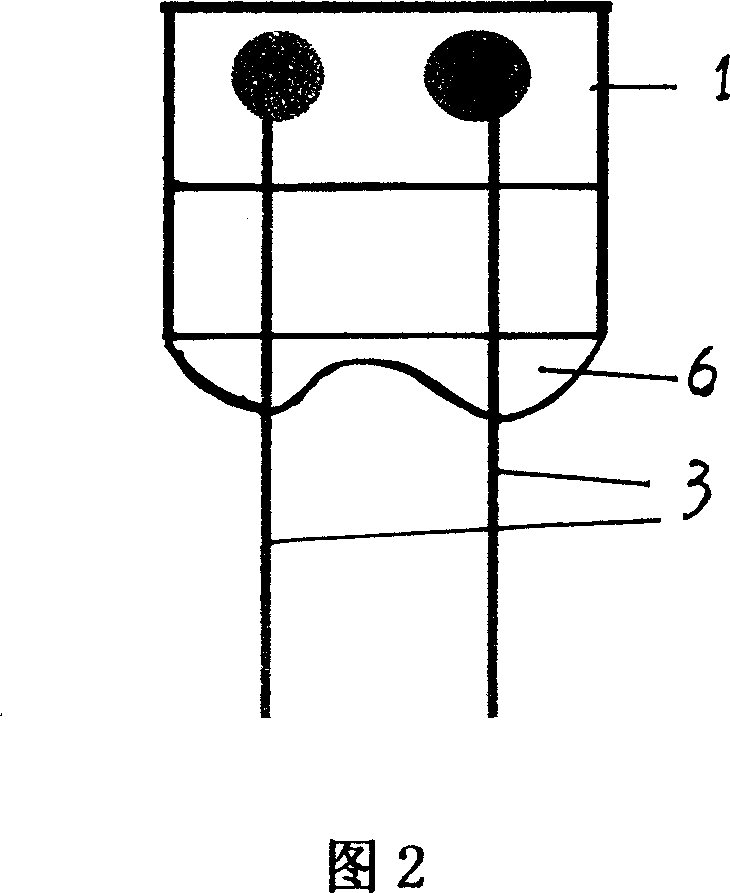

[0030] As shown in Figure 1 and Figure 2, the surface of the varistor 2 and the alloy type thermal fuse 4 are adjacent to each other and installed in the cavity 1, the gap and the cavity 1 are filled with alloy flux 7, and then sealed with epoxy resin The material 6 seals the opening of the cavity 1, and the piezoresistor pin 3 and the fuse pin 5 are arranged outside the opening of the cavity 1. When the varistor 2 heats up due to various factors, the heat can be transferred to the surrounding alloy flux 7 through its surface layer, and then the alloy flux 7 transfers the heat to the alloy fuse 4 until the alloy is heated and melted. Under the action of the alloy flux 7, it quickly shrinks to the two fuse pins 5 (as shown in Figure 2), thereby cutting off the circuit and separating the deteriorating piezoresistor 2 from the circuit, and the thermal response speed is very fast. Its structure is simple and compact.

Embodiment 2

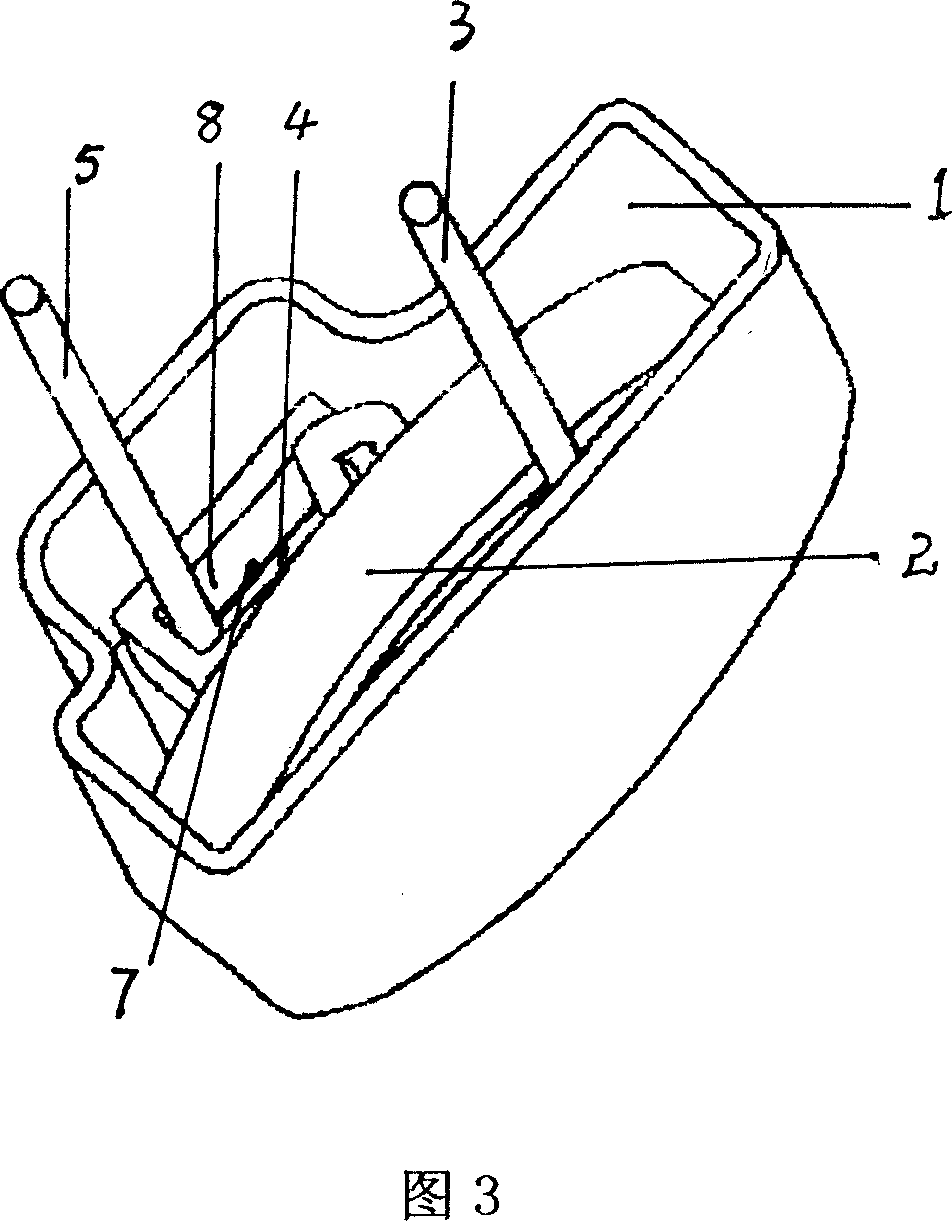

[0032] Figure 3 is a schematic diagram of two pin embodiments of the present invention, a pin 3 of the varistor 2 is connected with a pin 5 of the alloy type temperature fuse 4 and is sealed in the cavity; the varistor 2 and the alloy type temperature fuse The other pins of the fuse 4 respectively extend outside the cavity.

Embodiment 3

[0034] Figure 4 is a schematic diagram of three pin embodiments of the present invention, two pins 3 of the piezoresistor 2 are all extended outside the cavity, and one of the pins 3 is connected to a pin 5 of the alloy type thermal fuse; Another pin 5 of the thermal fuse 4 extends outside the cavity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com