Online deep dynamic level-temperature measuring system for geothermal well

A geothermal water well and temperature measurement technology, applied in thermometers, measuring devices, measuring heat, etc., can solve the problems that liquid level changes cannot be realized, the diameter of the sensing wire is large, and online measurement cannot be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] This invention is achieved like this.

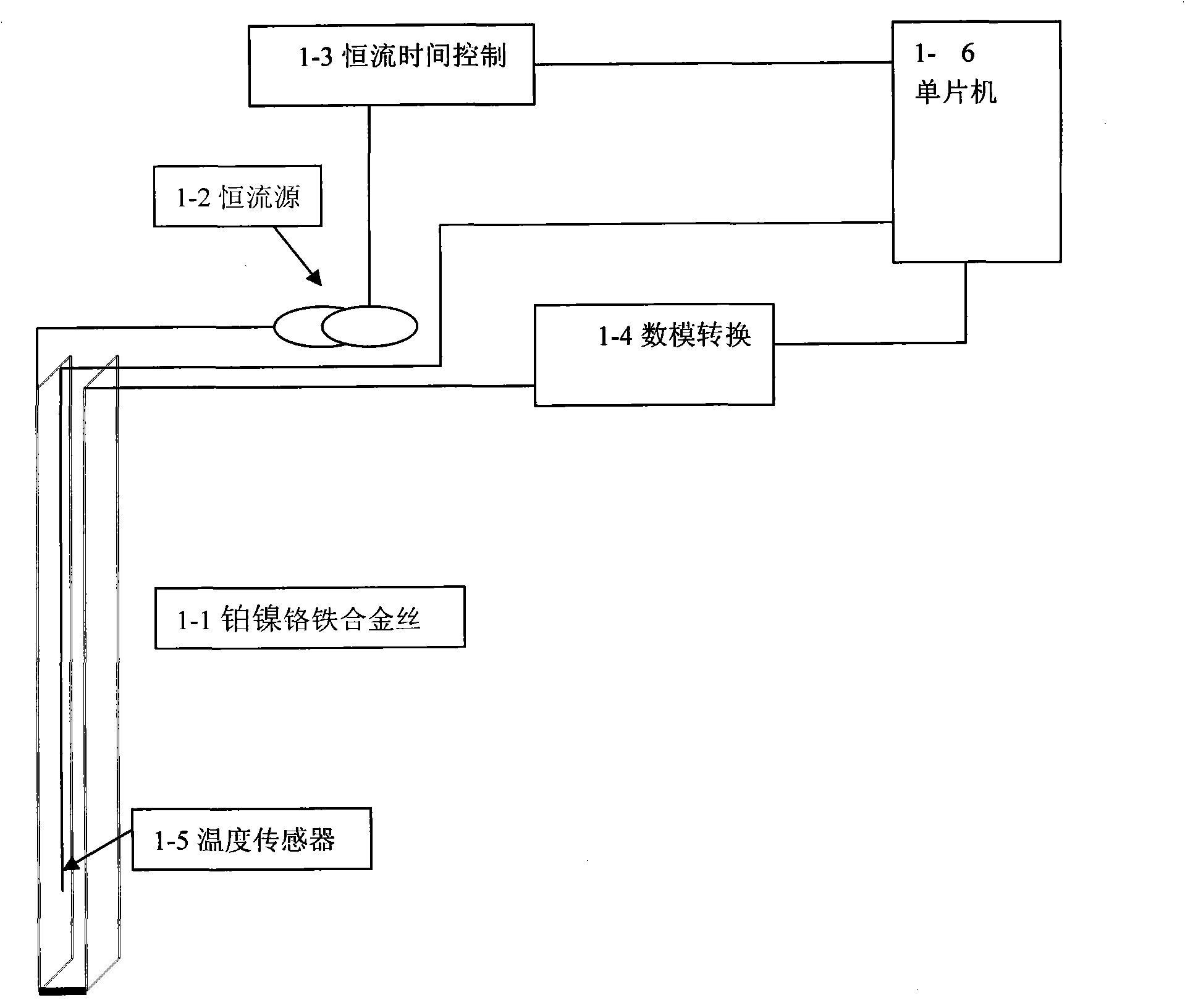

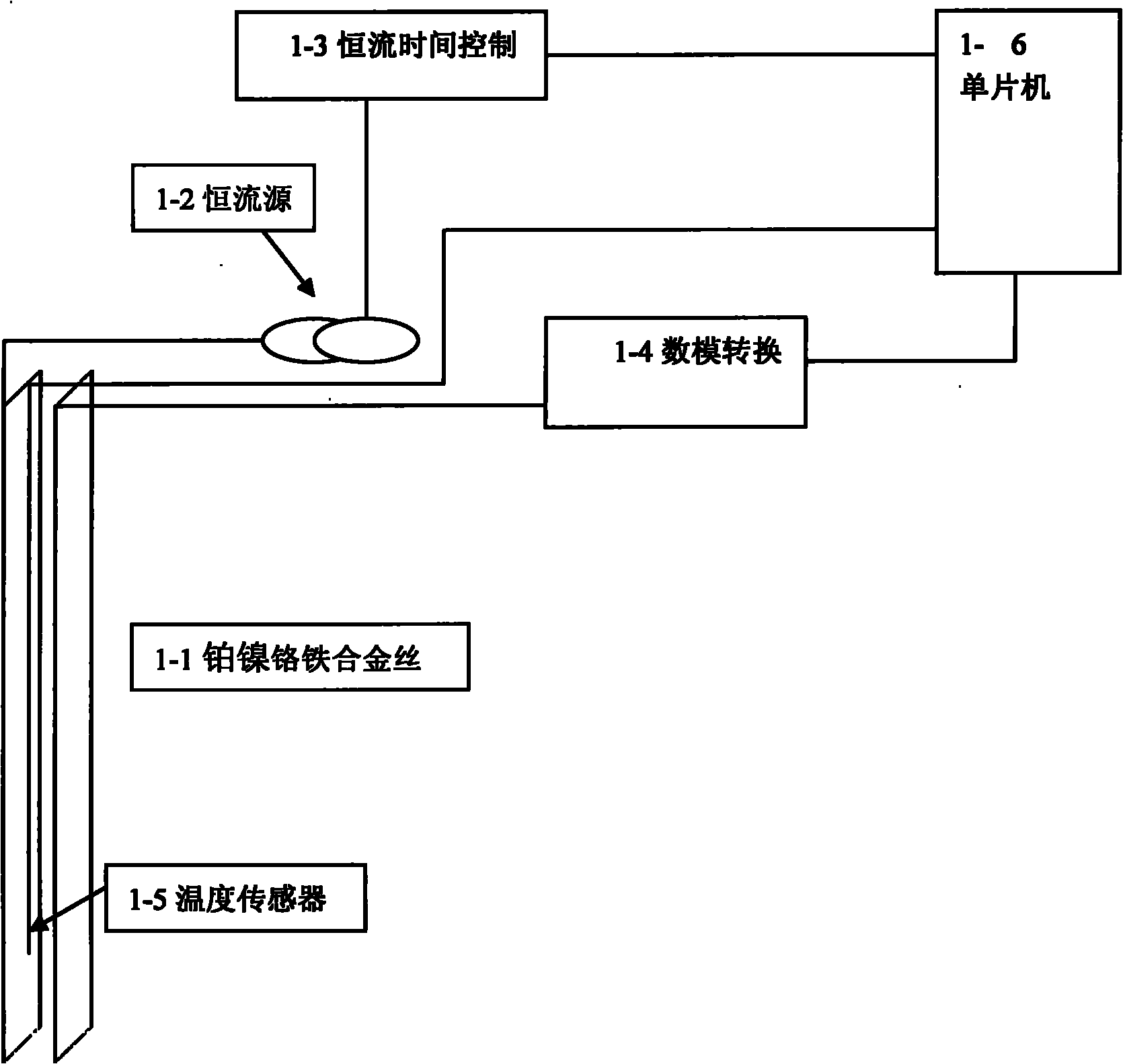

[0016] An online geothermal well deep dynamic liquid level-temperature measurement system, the temperature sensors 1-5 installed in the geothermal well are connected to single-chip microcomputers 1-6; The constant current source 1-2, the other end of the platinum nickel-chromium iron alloy wire 1-1 is connected to the digital-analog converter 1-4; the constant current source is connected to the constant current source switching time controller 1-3, the digital-analog converter 1-4 and the constant current source The flow source switching time controller is connected to the single-chip microcomputer 1-6.

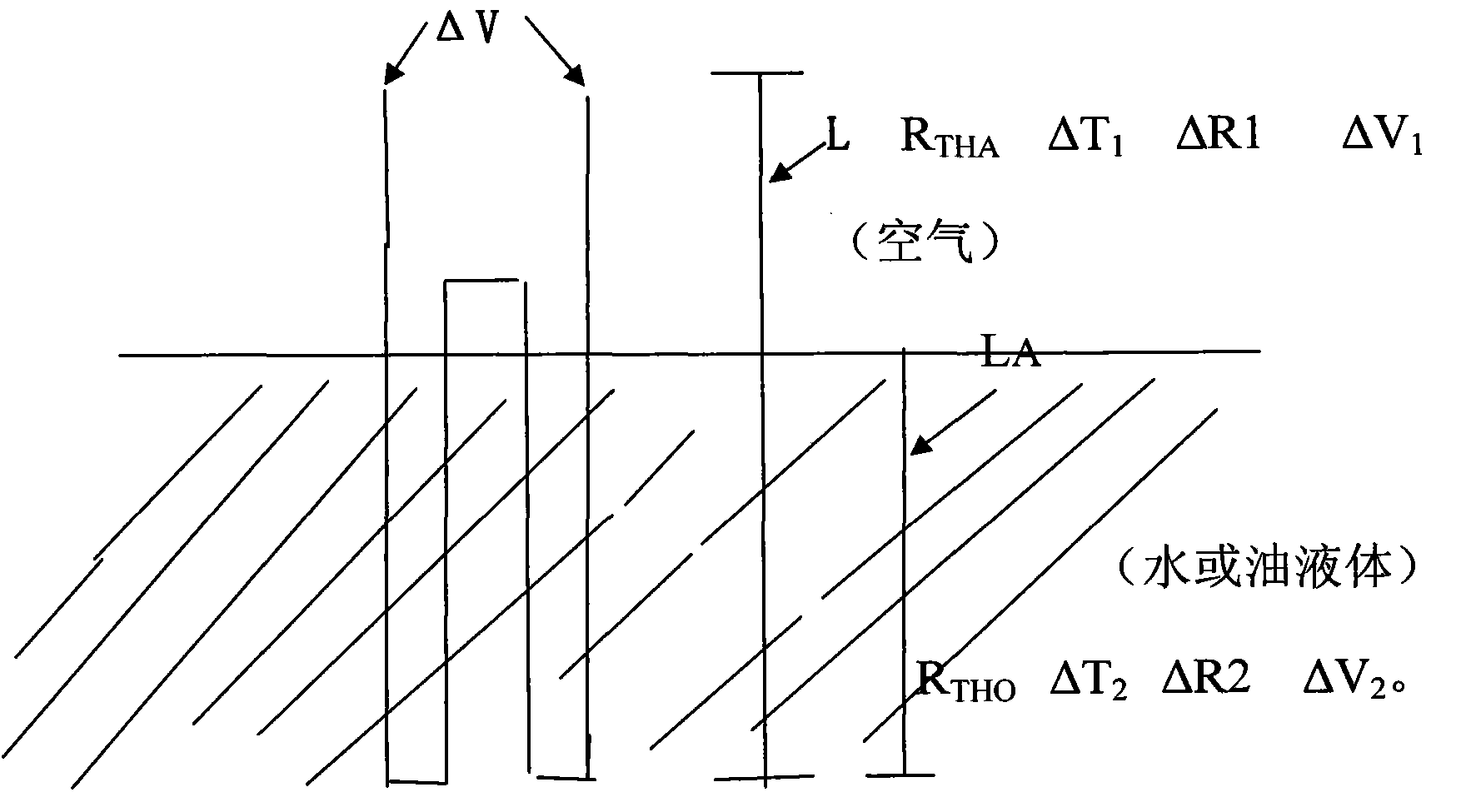

[0017] Platinum-nickel-chromium-iron alloy wire has a positive temperature coefficient and high thermal response speed. Place it in air and liquid, and pass a constant current to the platinum-nickel-chromium-iron alloy wire through the constant current source under the control of the switching time controller. Since the thermal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com