Silicon carbide vertical insulated gate bipolar transistor and production method thereof

A bipolar transistor and insulated gate technology, applied in the field of microelectronics, can solve the problems of increasing conduction power loss, weakening the conductance modulation effect, and being unfavorable for the parallel application of devices, so as to improve the switching speed of devices and reduce the switching loss of devices Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

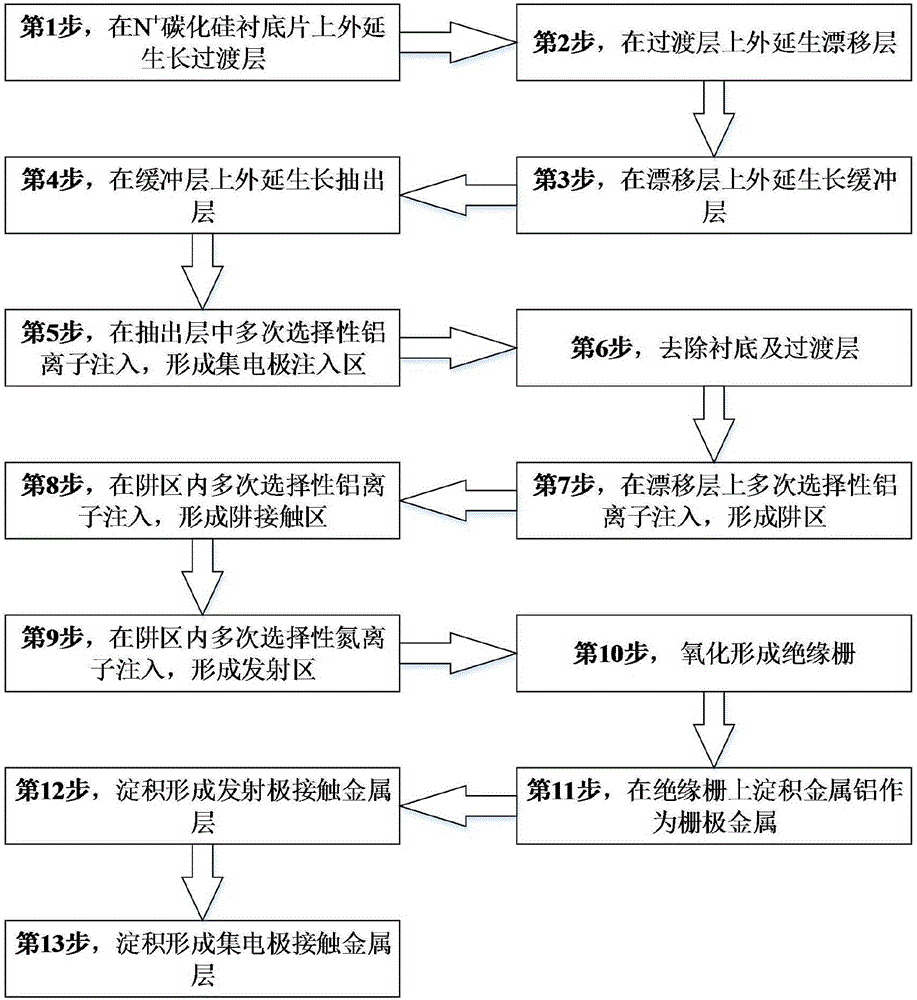

[0033] Step 1, epitaxially grow the transition layer on the N+ silicon carbide substrate, such as image 3 As shown, the N+ type silicon carbide substrate is first cleaned by RCA standard; then a transition layer with a thickness of 20 μm is epitaxially grown on the front side of the N+ type silicon carbide substrate by low pressure hot wall chemical vapor deposition.

[0034] It should be noted that the growth conditions of the transition layer are: the temperature is 1600° C., the pressure is 100 mbar, the reaction gas is silane and propane, and the carrier gas is pure hydrogen.

[0035] It should be noted that the RCA standard cleaning method was first created by Kern and Puotinen in the RCA laboratory of N.J.Princeton in 1965, and thus got its name. RCA is a typical wet chemical cleaning method that is still the most commonly used. The cleaning method mainly includes the following cleaning solutions.

[0036] (1), SPM:H 2 SO 4 / H 2 o 2 120~150℃ SPM has high oxidation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com