CeO2 system PTCR thermal sensitive ceramic material and preparation method thereof

A heat-sensitive ceramic and formula technology, applied in the field of new semiconductor ceramic materials and their preparation, can solve the problems of high lift-to-resistance ratio and less temperature-controlling materials for heat-sensitive ceramics, achieve stable performance, inhibit grain growth, and improve resistance to electricity. Effects of strength and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

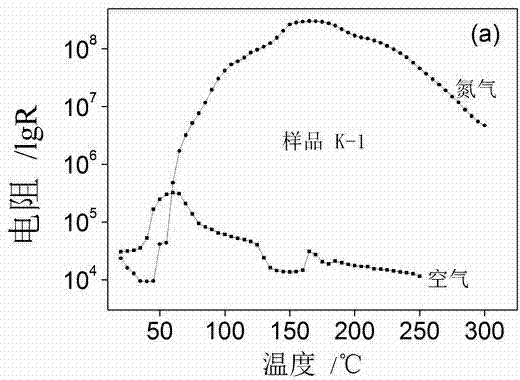

Embodiment 1

[0021] In this example, CeO 2 + 0.25 K 2 CO 3 + 0.003 D+ d Al 2 o 3 + 0.25 Bi 2 o 3 Carry out batching, wherein D is Nb 2 o 5 or Sb 2 o 3 , d=0~0.004, choose Bi as the initial raw material 2 o 3 、K 2 CO 3 , CeO 2 , Nb 2 o 5 、Al 2 o 3 , Sb 2 o 3 . Weigh after calculating the weight according to the molar ratio in the molecular formula, and the weighing quality is shown in Table 1:

[0022] Weighing according to the formula in the ingredient list 1, using zirconia balls and alcohol as the medium, according to the ratio of material: ball: alcohol = 1: 2.5: 1.5 (weight), put the above raw materials on the planetary mill at a speed of 280 rpm After ball milling for 4 hours and drying, the uniformly mixed oxide powder was obtained. Add 9wt% PVA (polyvinyl alcohol, concentration 10wt%) to the dried powder to granulate, and press a Φ10×2.0mm disc at a pressure of 10MPa.

[0023] The pressed discs were heat-treated in the atmosphere at 900°C for 2 hours (to ...

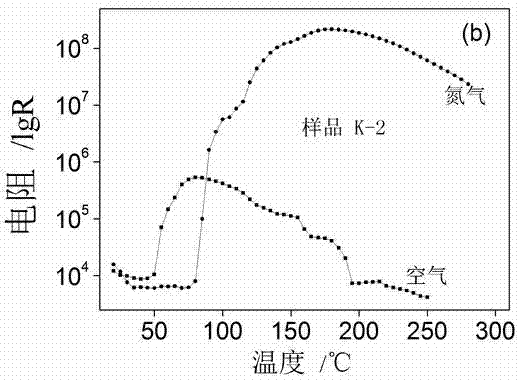

Embodiment 2

[0026] In this example, CeO 2 + 0.25 Na 2 CO 3 + c D+0.25Bi 2 o 3 Carry out batching, wherein D is Nb 2 o 5 or Sb 2 o 3 , c=0.002~0.003, choose Bi as the initial raw material 2 o 3 、Na2 CO 3 , CeO 2 , Nb 2 o 5 , Sb 2 o 3 . Weigh after calculating the weight according to the molar ratio in the molecular formula, and the weighing quality is shown in Table 3:

[0027] Weighing according to the formula in the ingredient list 1, using zirconia balls and alcohol as the medium, according to the ratio of material: ball: alcohol = 1: 2.5: 1.5 (weight), put the above raw materials on the planetary mill at a speed of 280 rpm After ball milling for 4 hours and drying, the uniformly mixed oxide powder was obtained. Add 9wt% PVA (polyvinyl alcohol, concentration 10wt%) to the dried powder to granulate, and press a Φ10×2.0mm disc at a pressure of 10MPa.

[0028] The pressed discs were heat-treated in the atmosphere at 900°C for 2 hours (to make them fully react in solid p...

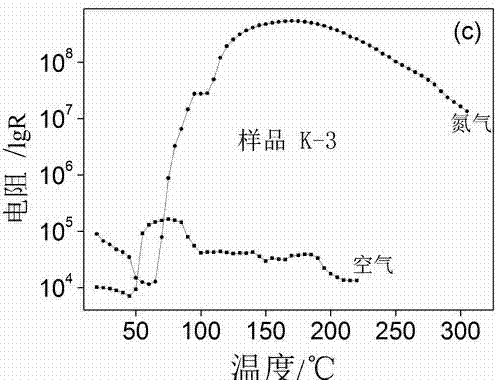

Embodiment 3

[0031] In this example, CeO 2 + a Na 2 CO 3 + b K 2 CO 3 + 0.003 Sb 2 o 3 + 0.25 Bi 2 o 3 For batching, a, b=0.10-0.15, the initial raw material selection Bi 2 o 3 、K 2 CO 3 、Na 2 CO 3 , CeO 2 , Sb 2 o 3 . Weigh after calculating the weight according to the molar ratio in the molecular formula, and the weighing quality is shown in Table 5:

[0032]

[0033] Weighing according to the formula in the ingredient list 1, using zirconia balls and alcohol as the medium, according to the ratio of material: ball: alcohol = 1: 2.5: 1.5 (weight), put the above raw materials on the planetary mill at a speed of 280 rpm After ball milling for 4 hours and drying, the uniformly mixed oxide powder was obtained. Add 9wt% PVA (polyvinyl alcohol, concentration 10wt%) to the dried powder to granulate, and press a Φ10×2.0mm disc at a pressure of 10MPa.

[0034] The pressed discs were heat-treated in the atmosphere at 900°C for 2 hours (to make them fully react in solid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| lift to drag ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com