Plate type pulsating heat pipe fresh air heat regenerator

A pulsating heat pipe and regenerator technology, applied in indirect heat exchangers, space heating and ventilation, space heating and ventilation details, etc., can solve the problem of alternating pollution of old and new winds, easy air leakage of reversing devices, and difficult manufacturing and other problems, to achieve the effect of fast thermal response, high heat exchange efficiency and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings. This embodiment provides detailed implementation methods and specific operating procedures on the premise of the technical solutions of the present invention, but the protection scope of the present invention is not limited to the following implementations example.

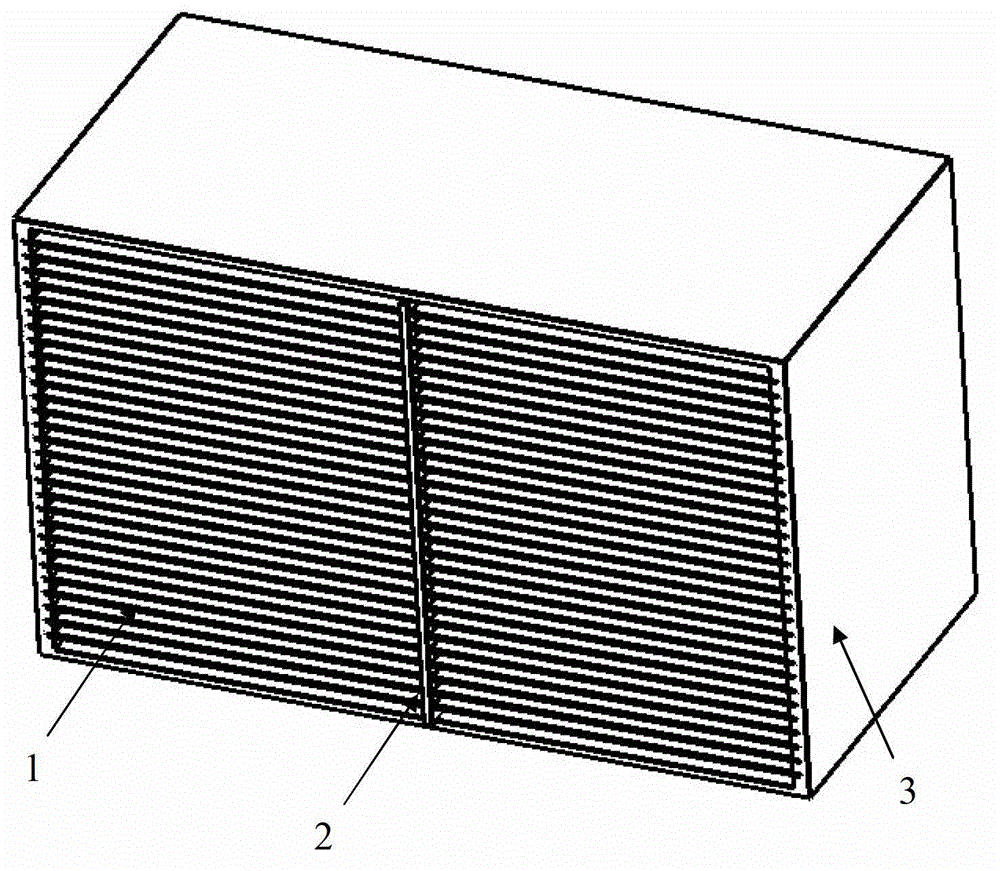

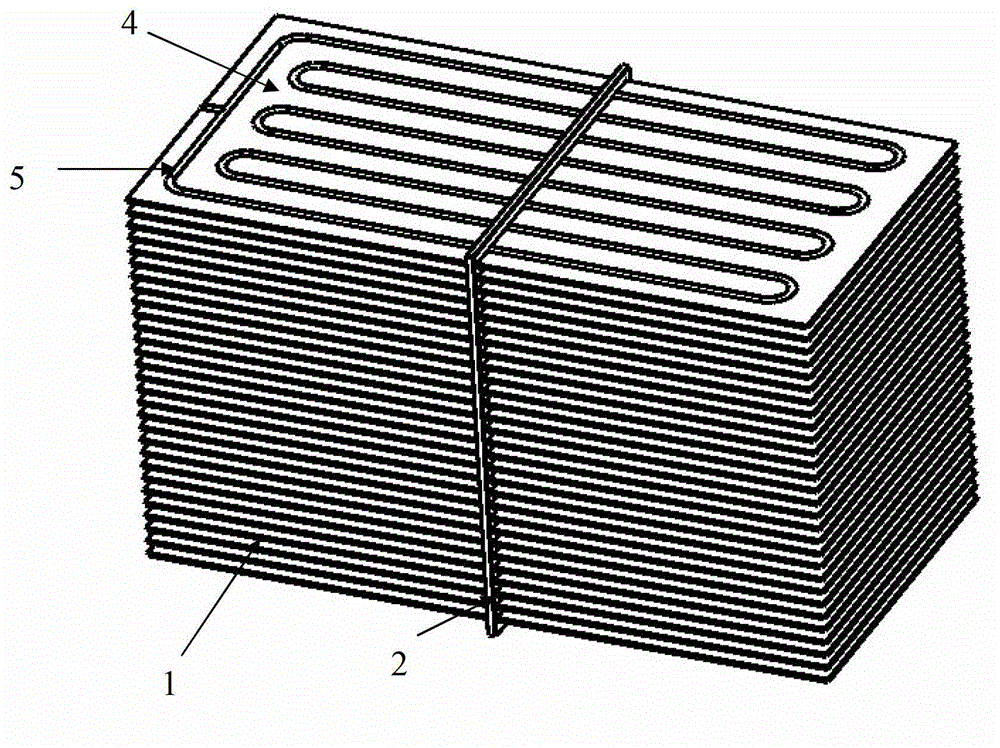

[0042] Please refer to figure 1 with figure 2 , the plate type pulsating heat pipe fresh air regenerator shown in the figure is composed of a plate type pulsating heat pipe heat exchange plate group 1, a partition 2 and a heat exchanger shell 3, wherein the partition 2 is in the center of the entire regenerator, and the plate type pulsating heat pipe exchanging The heat plate group 1 is inserted through the partition plate 2 and inserted into the heat exchanger shell 3 as a whole.

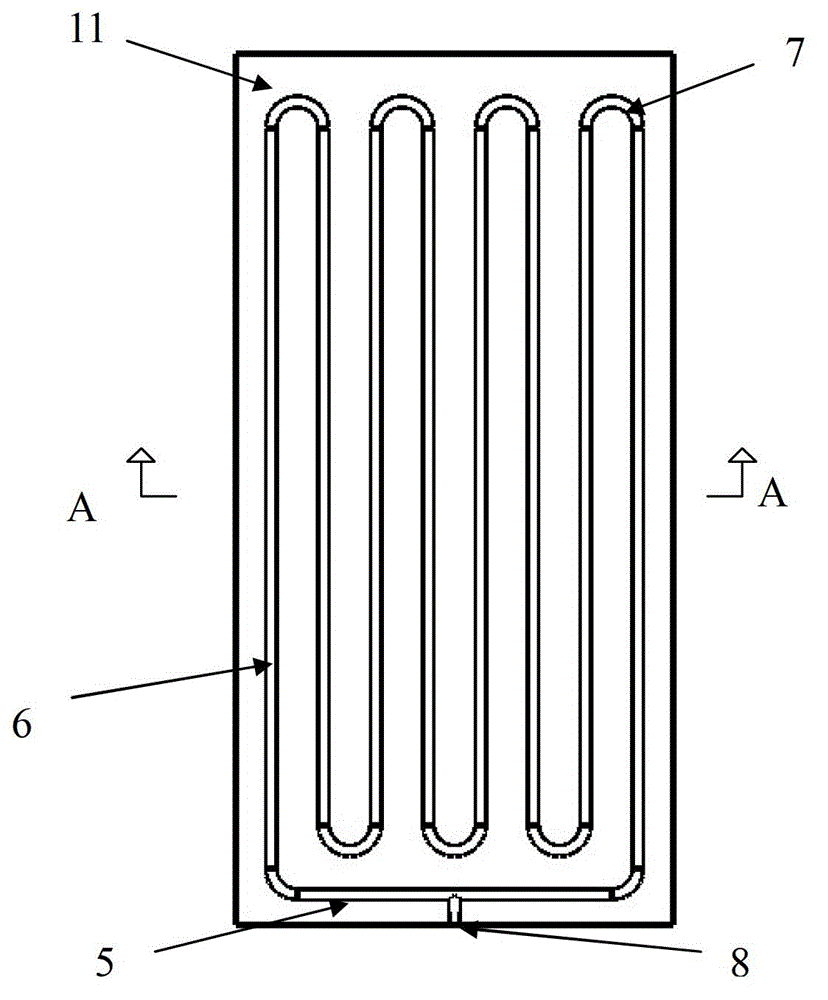

[0043] The heat exchanger housing 3 is made of stainless steel, please refer to Image 6 with Figure 7 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com