Yttrium-doped zirconia heating element for heating incombustible low-temperature cigarette and manufacturing method thereof

A heating-not-burning and low-temperature cigarette technology, which is applied to electrical components, ohmic resistance heating, tobacco, etc., can solve problems that affect the experience of smokers, unfavorable heating of heating elements, and poor toughness of alumina ceramics, so as to improve the user experience , Solve the effects of power attenuation and slow heating speed, fast heating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

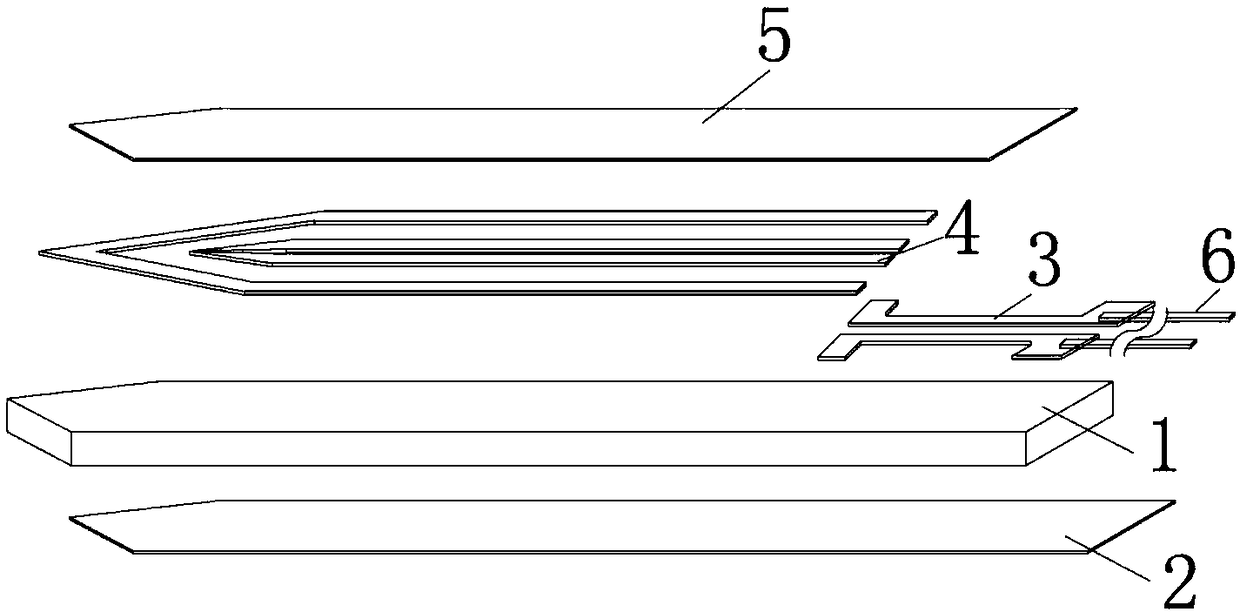

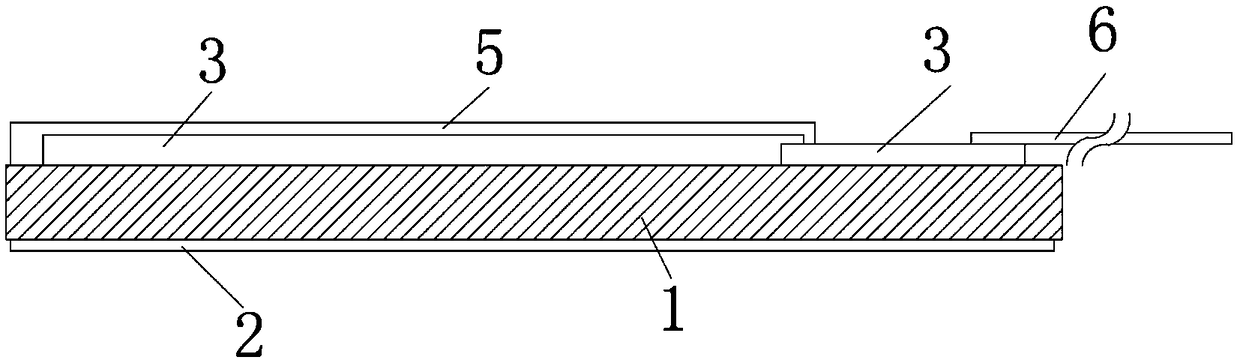

[0038] A heating element of yttrium-doped zirconia in a heat-not-burn low-temperature cigarette in this embodiment, such as figure 1 As shown, it includes a yttrium-doped zirconia ceramic substrate 1, and an insulating film layer 2 is printed on one surface of the yttrium-doped zirconia ceramic substrate 1 to reduce the friction between the yttrium-doped zirconia ceramic substrate 1 and cigarettes and other parts. One board surface is printed with a wire pad film 3 and a heating power resistance film 4, the heating power resistance film 4 is connected to the wire on the wire pad film 3, and also includes an insulating protection layer 5, and the insulation protection layer 5 covers the heating power resistance film 4. The wire pad film 3 is welded with a lead pin 6 that can be electrically connected to an external power supply, wherein, as figure 2 As shown, the length of the insulating protective layer 5 is shorter than that of the yttrium-doped zirconia ceramic substrate 1 ...

Embodiment 2

[0042] A method for manufacturing a heat-not-burn low-temperature cigarette heating element of yttrium-doped zirconia in this embodiment includes the following steps:

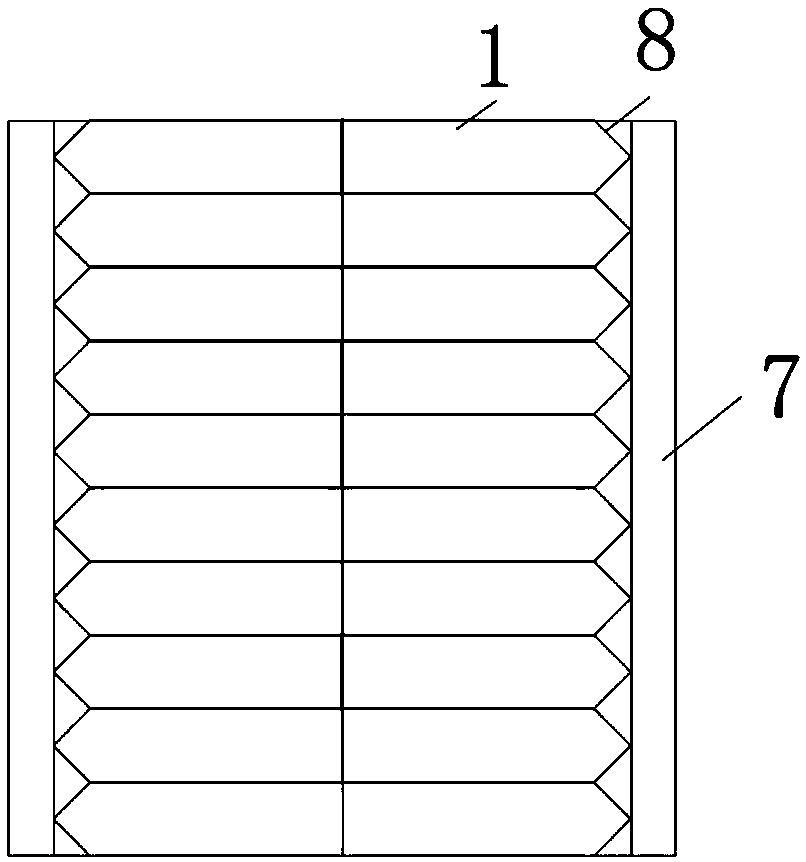

[0043] Step 1, such as image 3As shown, the yttrium-doped zirconia ceramic plate 7 is used, and the yttrium-doped zirconia ceramic substrate 1 is cut on the yttrium-doped zirconia ceramic plate 7, so that the front end of the yttrium-doped zirconia ceramic substrate 1 is sharp; the specific cutting The method is as follows: on the yttrium-doped zirconia ceramic plate 7, the scribed groove 8 is formed to form several yttrium-doped zirconia ceramic substrates 1 and margins 9, and the scribed groove is helpful for subsequent processes to make the yttrium-doped zirconia ceramic plate 7 It is divided into small units, and a single yttrium-doped zirconia ceramic substrate 1 is obtained by splitting the cutting groove 8 .

[0044] Step two, such as Figure 4 As shown, using the thick film film forming technology, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com