Method for spraying and desalting through residual pressure of reverse osmosis concentrated water

The technology of reverse osmosis concentrated water and reverse osmosis device is applied in the concentrated water purification of reverse osmosis system and the field of reverse osmosis concentrated water residual pressure spray desalination, which can solve the problems of increasing water production cost and wasting energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

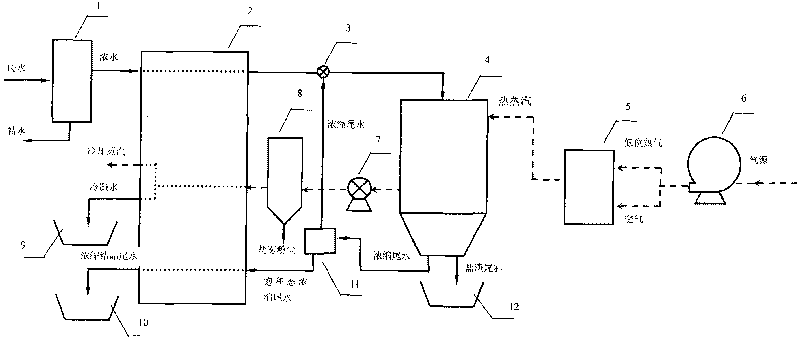

[0049] 1) Waste water is separated into concentrated water by reverse osmosis device (1) under high pressure; the air source (which can be air and low-grade hot steam) enters the temperature control heater (5) from the blower (6), which is based on The actual conditions such as the amount and temperature of the concentrated water needed to evaporate, so that the inflow gas is controlled at the normal operating temperature (50~90℃), and enters the atomization concentration chamber by the suction effect of the induced draft fan (7);

[0050] 2) The concentrated water is preheated by the heat exchange system (2). The heat exchange system (2) mainly exchanges heat between the atomized water vapor, the concentrated tail water and the reverse osmosis concentrated water, and the water vapor, The heat in the concentrated tail water is transferred to the reverse osmosis concentrated water. Among them, the heat exchange between steam and concentrated water is carried out by an in-line stea...

Embodiment 2

[0057] 1) Waste water is separated into desalinated refined water and waste concentrated brine (concentrated water) through reverse osmosis device under high pressure of 2.5MPa;

[0058] 2) After the concentrated water is preheated by the heat exchange system (2) (40°C), it enters the atomization concentration chamber (4) directly through the mixing exchanger (3), and uses the energy of the concentrated water to pass through the improved pressure rotary atomization Device

[0059] 3) The atomized concentrated water droplets are contacted with the hot air stream treated by the temperature-controlled heating system (90°C) to form water vapor and prepare concentrated tail water;

[0060] 4) The induced draft fan (7) takes the water vapor and air flow out of the evaporation chamber and enters the gas-powder separator (8) to remove the salty substance powder entrained in the air, and then condense it into fresh water by the condensate collector (9). Be recycled

[0061] 5) After concentra...

Embodiment 3

[0064] 1) Waste water is separated into desalinated refined water and waste concentrated brine (concentrated water) through reverse osmosis device (1) under high pressure of 7MPa;

[0065] 2) After the concentrated water is preheated by the heat exchange system (2) (40°C), it enters the atomization concentration chamber (4) directly through the mixing exchanger (3), and uses the energy of the concentrated water to pass through the improved pressure rotary atomization Device

[0066] 3) The atomized concentrated water droplets are contacted with the dry hot air stream treated by the temperature control heating system (90°C) to form water vapor and prepare concentrated tail water;

[0067] 4) The water vapor and air flow are taken out of the evaporation chamber by the induced draft fan (7) into the gas-powder separator (8) to remove the salt and powder entrained in the air, and then condensed into fresh water by the condensate collector (9) And be recycled;

[0068] 5) After concentrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com