High-concentration sewage treatment method

A sewage and pretreatment technology, applied in the direction of energy wastewater treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of non-removal of biodegradable substances, long treatment time, large power consumption, etc., and achieve improved biochemical performance, improvement of biodegradability, effect of load reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

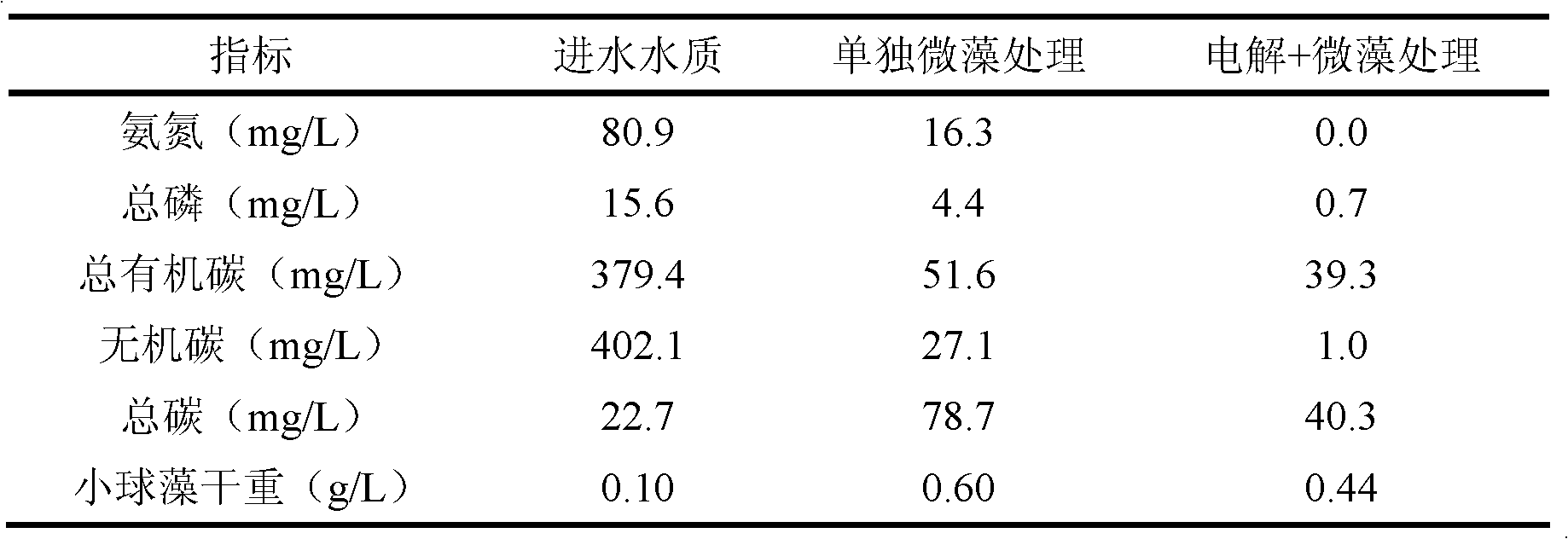

[0041] Embodiment 1: the effect test of the inventive method to synthetic domestic sewage treatment

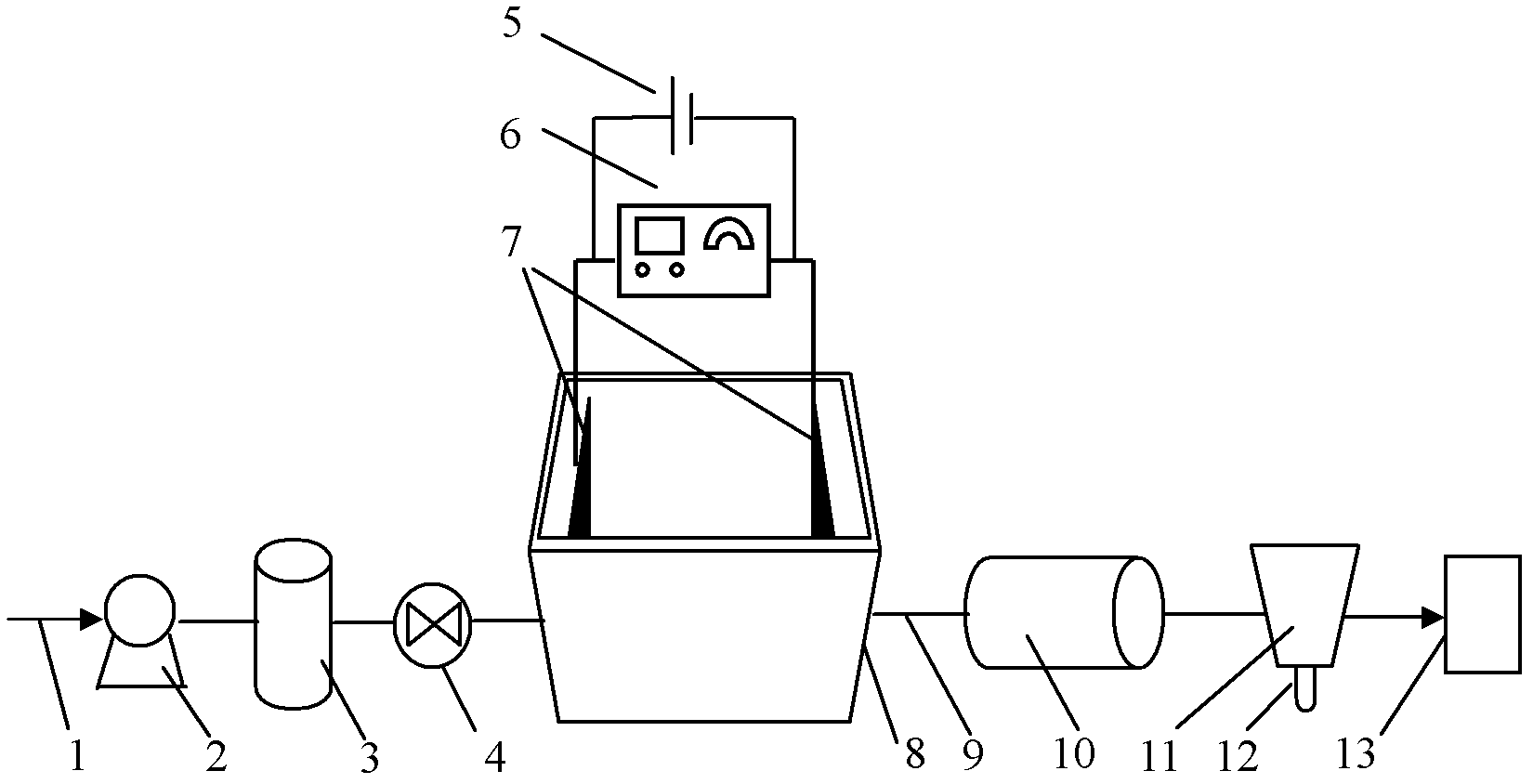

[0042] Sewage treatment in figure 1 in the device shown.

[0043] The domestic sewage is used as the sewage for the test. The domestic sewage 1 is passed into the water storage tank 3 through the sewage pump 2, and the electrolyte of 2g / L sodium chloride is added to the domestic sewage (2L) in the water storage tank 3, stirred until it is completely dissolved, and then passed through the control The valve 4 passes the mixed solution into the electrolytic cell 8 . Platinum-plated titanium alloy plate electrodes are used, and the electrolysis operating conditions are set as follows: the voltage between the plates is 15V, the distance between the plates is 20mm, and the electrolysis time is 2h. After the electrolysis, cool the mixed solution to room temperature, and adjust the pH value to 7.0-9.0. Then inoculate chlorella in the mixed solution after adjusting the pH value, the...

Embodiment 2

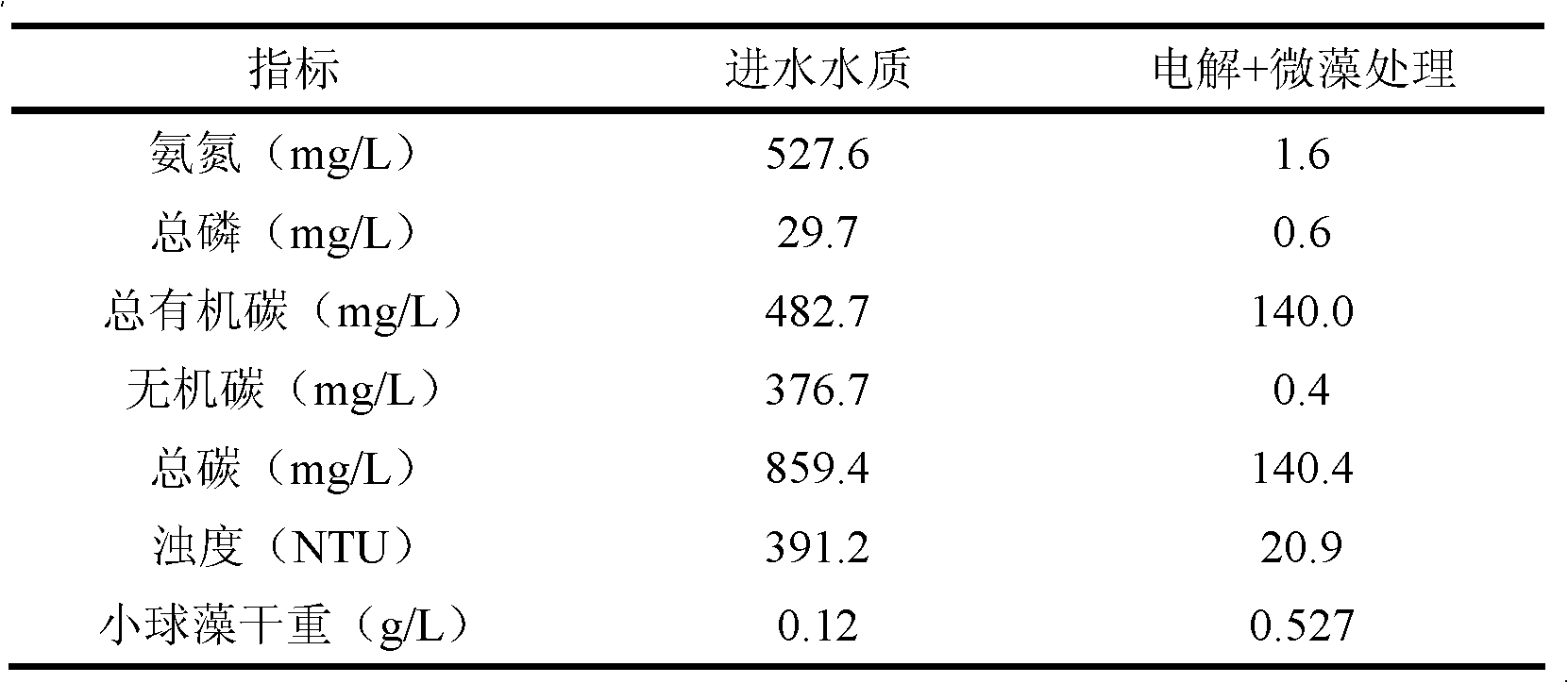

[0048] Embodiment 2: The processing effect of the method of the present invention on the biogas slurry of livestock and poultry farms

[0049] Dilute the biogas slurry 10 times as the sewage for the test, put 2g / L sodium chloride as the electrolyte into 2L of the diluted biogas slurry, stir until completely dissolved, and pour the mixed solution into the electrolytic cell. Platinum-plated titanium alloy electrodes are used, and the electrolysis operating conditions are set as follows: the voltage between the plates is 15V, the distance between the plates is 20mm, and the electrolysis time is 2h. After the electrolysis, the mixed solution is cooled to room temperature, and the pH value is adjusted to 7.0-9.0. Inoculate chlorella in the mixed solution, the inoculation concentration is 100mL / L (inoculation solution / biogas slurry), the inoculation amount of chlorella is 0.12g dry weight / L, the culture solution is put into the light incubator, and the culture conditions are: tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com