Device and method for laser micro shock dieless forming

A technology of moldless forming and laser shock, which is applied in the field of micro-electromechanical systems (Micr), can solve the problems of high transmission speed and placement accuracy, and the traditional method of blank clamping and positioning is no longer available, so as to achieve a wide range of applications and avoid Unfavorable structure and performance, high filming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

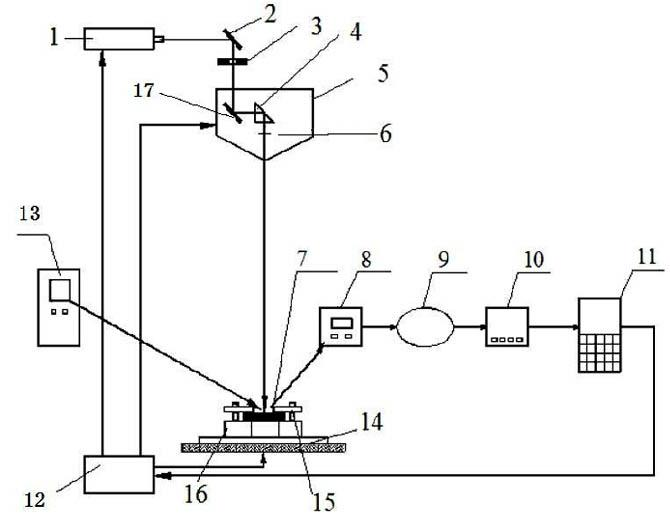

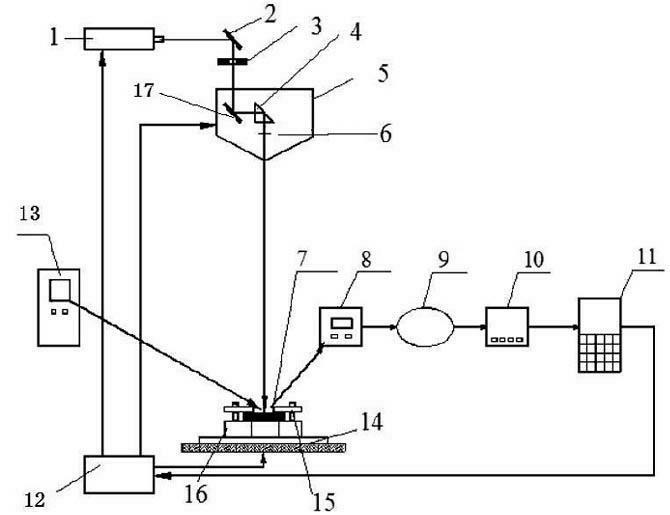

[0028] Such as figure 1 A laser micro-shock dieless forming device shown includes a laser 1, an optical path guiding system, a fixture system, a detection system and a control system; the optical path guiding system includes: a first reflector 2, a collimator 3 and The laser impact head 5; the laser impact head 5 is arranged in order from the light entering order, including: the second reflector 17, the triangular prism 4 and the focusing mirror 6; the tooling fixture system includes: a three-dimensional workbench 14, a fixture 15 , fixture base 16; the detection system includes: synchrotron radiation light source 13, detector 8, amplifier 9, pulse height analyzer 10, counter 11; the control system adopts industrial computer 12.

[0029] This embodiment also discloses a method of laser micro-impact moldless forming, the specific steps are as follows:

[0030] (A) Put the sample system in the tooling fixture system of the laser micro-impact moldless forming device, the samp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com