Plate multipoint forming device with crease resistant functions

A multi-point forming and functional technology, applied in the field of mechanical engineering, can solve the problems of increasing mold making costs and mold adjustment time, reducing the utilization rate of sheet metal, complex mold structure, etc., achieving easy automatic control, improving utilization rate of sheet metal, The effect of reducing the shaping time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

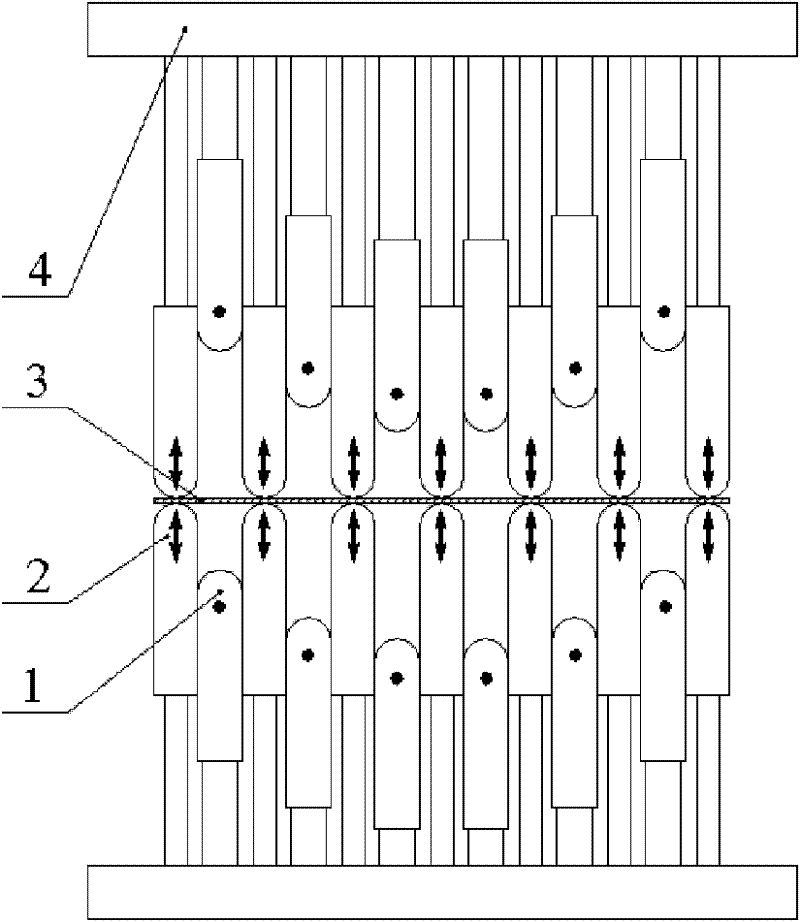

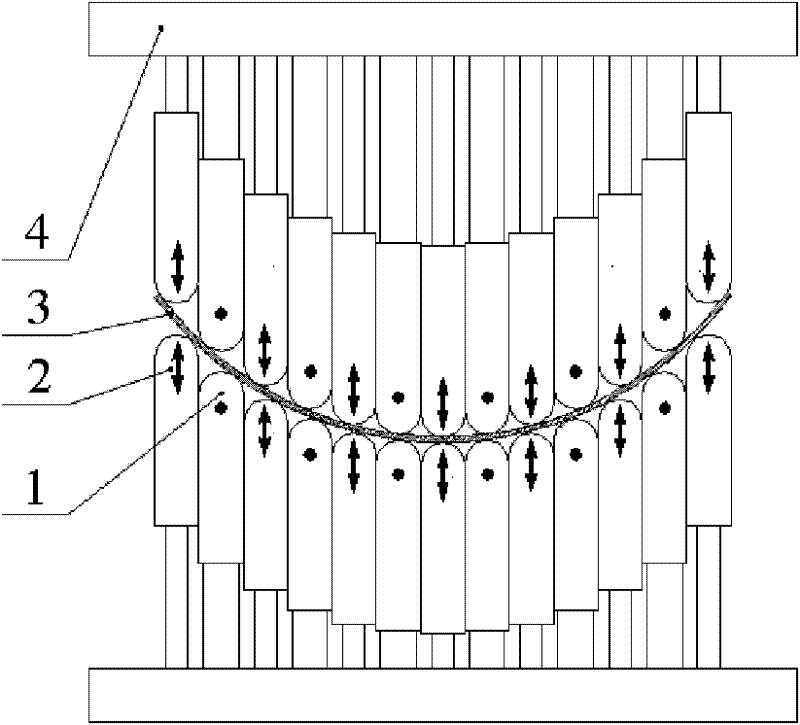

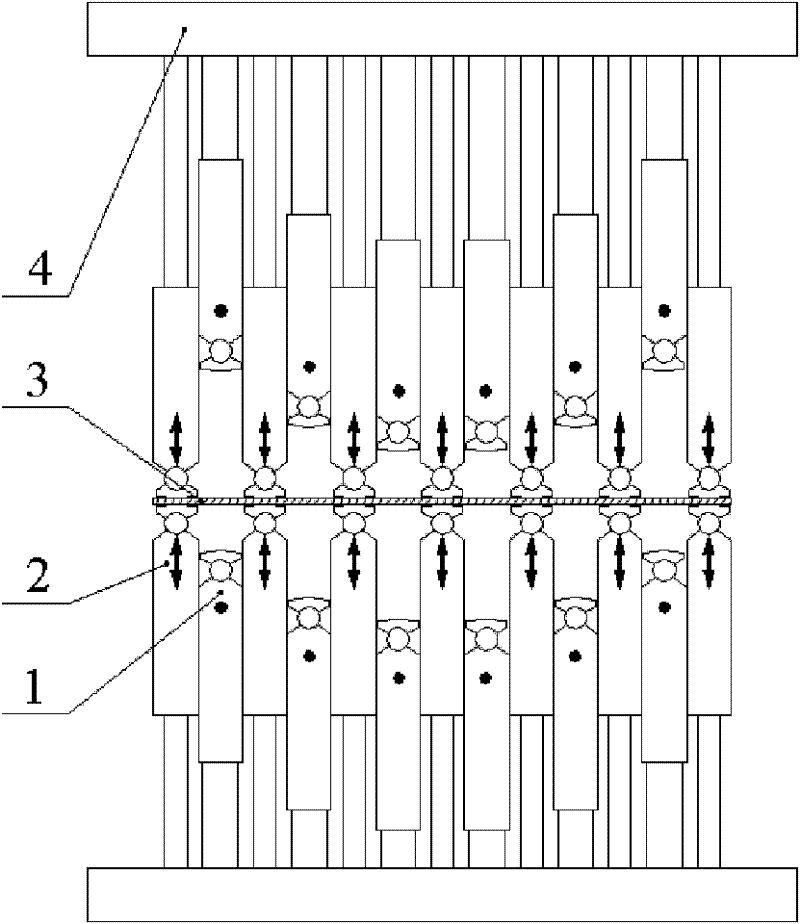

[0024] The specific content and working process of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0025] The plate multi-point forming device with anti-wrinkle function of the present invention is mainly composed of a shape adjusting unit 1, a material clamping unit 2, a unit fixing plate 4 and a loading mechanism. A plurality of shape-adjusting units 1 and a plurality of clamping units 2 are fixed on the fixed plate 4. The shape-adjusting units 1 and the clamping units 2 are arranged in a staggered manner. The units are arranged symmetrically. Of course, units of the same category above and below can also be arranged in a staggered arrangement as required. Before forming, multiple height-adjustable shape-adjusting units 1 use the shape-adjusting mechanism to make the envelope surface become the target curved surface contour, and multiple passively displaced clamping units 2 clamp the sheet 3 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com