Natural focusing type ultrasonic atomization nozzle

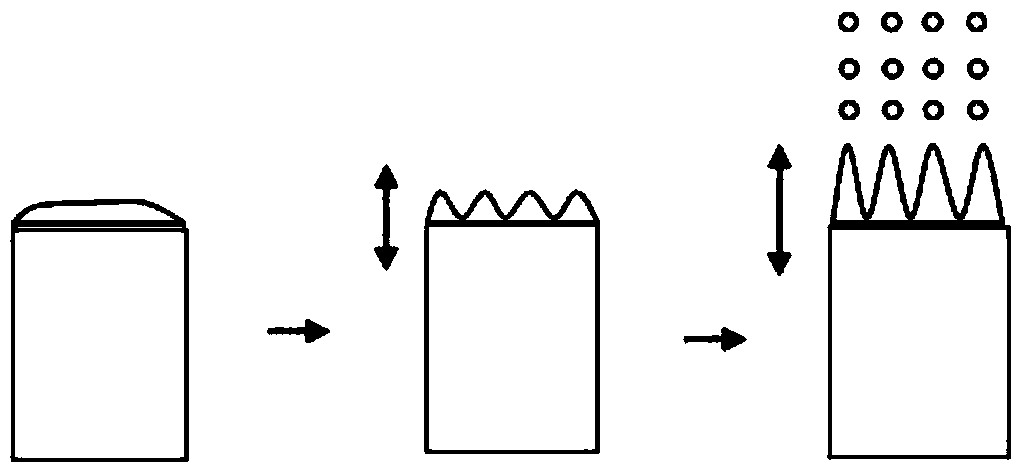

An ultrasonic atomization and natural focusing technology, which is applied in spraying devices, liquid spraying devices, printing, etc., can solve the problems of liquid splashing in the center hole, small maximum liquid flow rate, and short spraying distance, so as to achieve stable atomization beam and low gas consumption. Reduce the effect of long spray distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

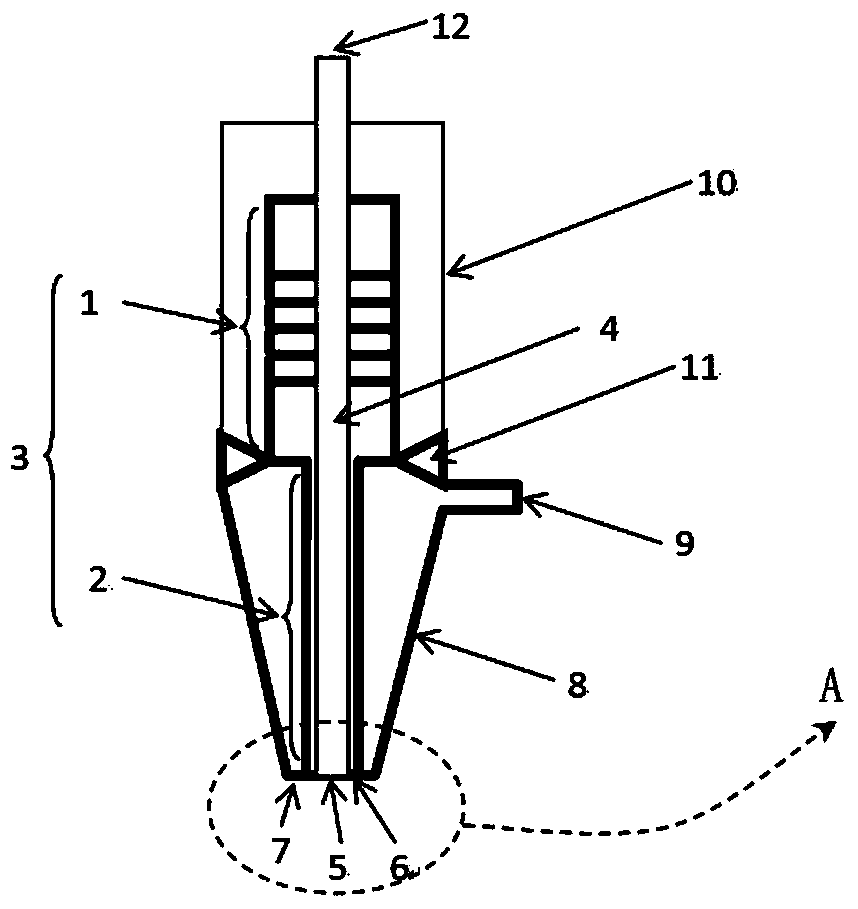

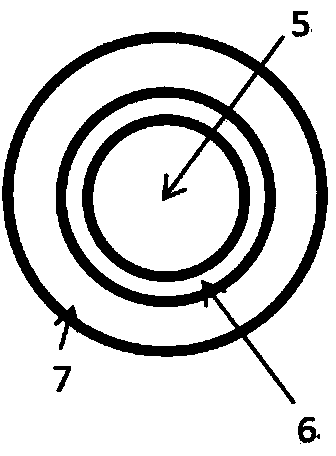

[0046] Such as figure 2 , is a structural schematic diagram of this embodiment; a natural focusing ultrasonic atomizing nozzle, including an ultrasonic atomizing transducer 3 , an air channel 4 , a liquid nozzle 8 and a housing 10 .

[0047] The ultrasonic atomization transducer 3 includes a piezoelectric vibration stack 1 and an ultrasonic horn 2 .

[0048] The function of the piezoelectric vibrating pile 1 is to generate ultrasonic vibration by using the inverse piezoelectric effect; the function of the ultrasonic horn 2 is to amplify the amplitude generated by the piezoelectric pile. The piezoelectric vibration stack 1 and the ultrasonic horn 2 form an ultrasonic atomization transducer 3 . The vibration velocity of the ultrasonic atomization transducer 3 in this embodiment is greater than 5 m / s.

[0049] The ultrasonic atomization transducer 3 in this embodiment is arranged in the casing 10 , the liquid nozzle 8 is fixedly arranged below the casing 10 through the shock-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com