Multi-shaft precision drilling machine tool

A precision drilling and machine tool technology, applied in the direction of boring/drilling, drilling/drilling equipment, metal processing machinery parts, etc., can solve the problem of inability to meet high-efficiency, high-standard production needs, equipment rigidity, and poor stability , single types of processed products, etc., to achieve the effect of convenient and fast processing, reduced processing costs, and a wide range of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

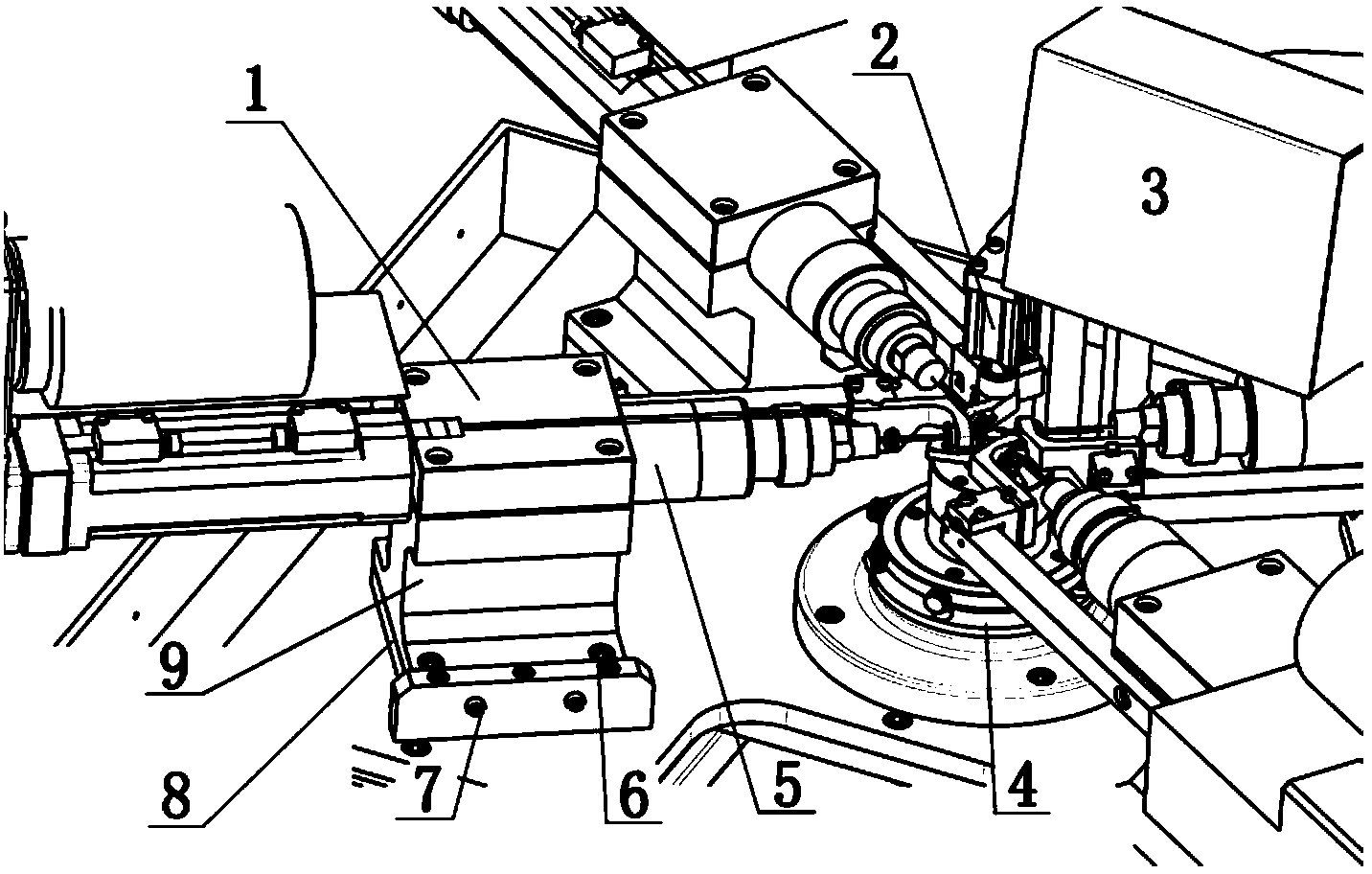

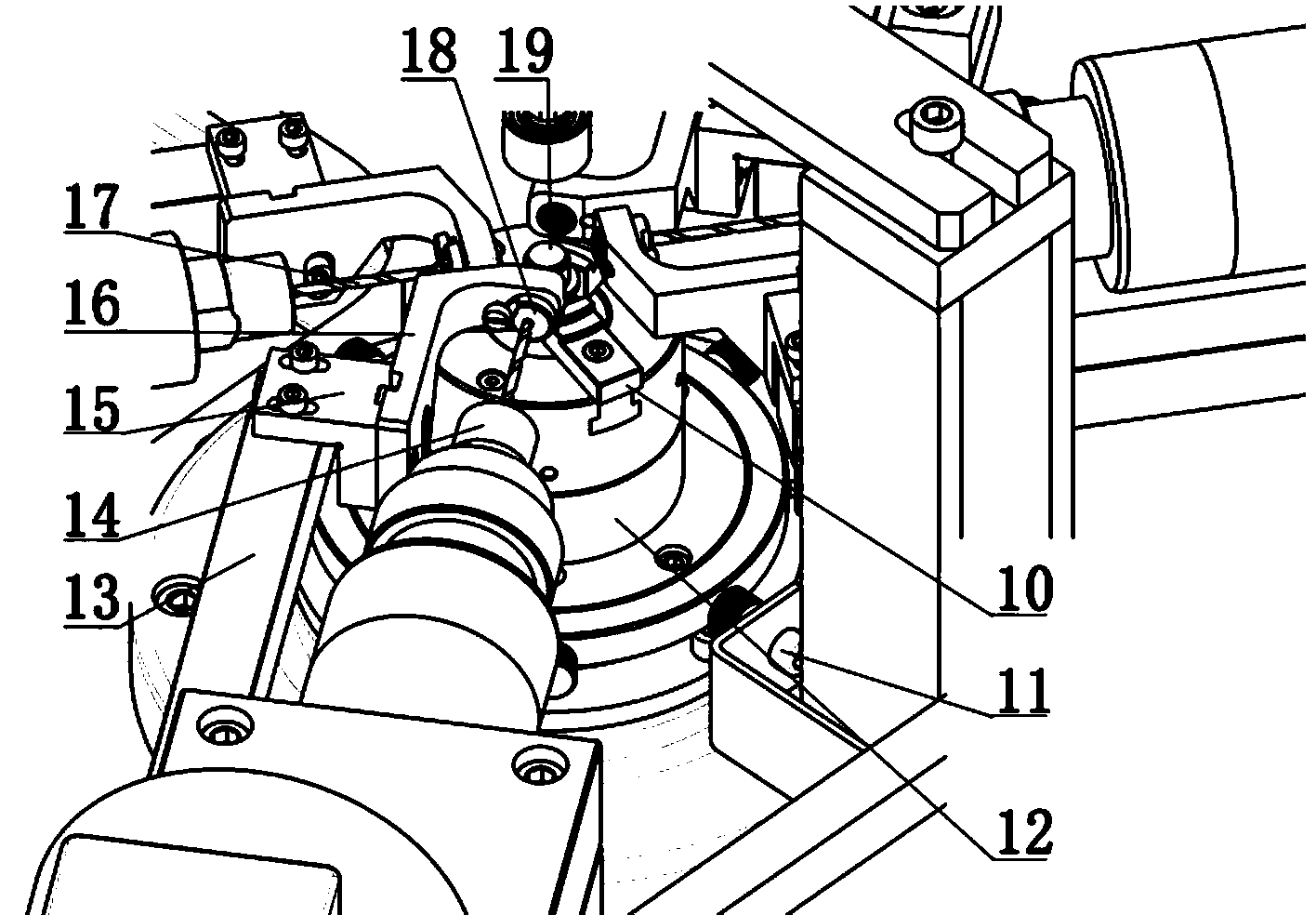

[0012] according to Figure 1~2 The specific structure of the present invention will be described in detail. The multi-axis precision drilling machine tool includes a frame, a working platform on the frame, a support 9 fixed on the working platform, a power head 5 installed on the support, an indexing plate 4 installed on the working platform, a peripheral To the sensor 11 arranged on the index plate 4, the chuck 12 installed on the index plate 4, the workpiece clamping mechanism, the drill sleeve clamping mechanism, the pneumatic reversing mechanism, the cooling system and other parts. Wherein, bearing 9 is fixed by bearing screw 6, and bearing 9 and power head 5 are four, and power head 5 is supported by bearing 9 and is pressed and installed on bearing 9 by bearing gland 1, and four drill bits 17 are respectively clamped on the main shaft of each power head 5 by the lock nuts 14 of each power head. The four supports 9 are fixed on the same working platform through long ke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com