Filter case stretching material falling device

A technology of blanking device and filter, which is applied in the direction of stripping device, forming tool, metal processing equipment, etc. It can solve the problems of no blanking table or blanking device, difficult to solve the problem of production positioning, high labor intensity and human resources, etc. , to achieve the effect of reducing labor costs, shortening the processing cycle, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be described in further detail below with reference to the drawings and embodiments.

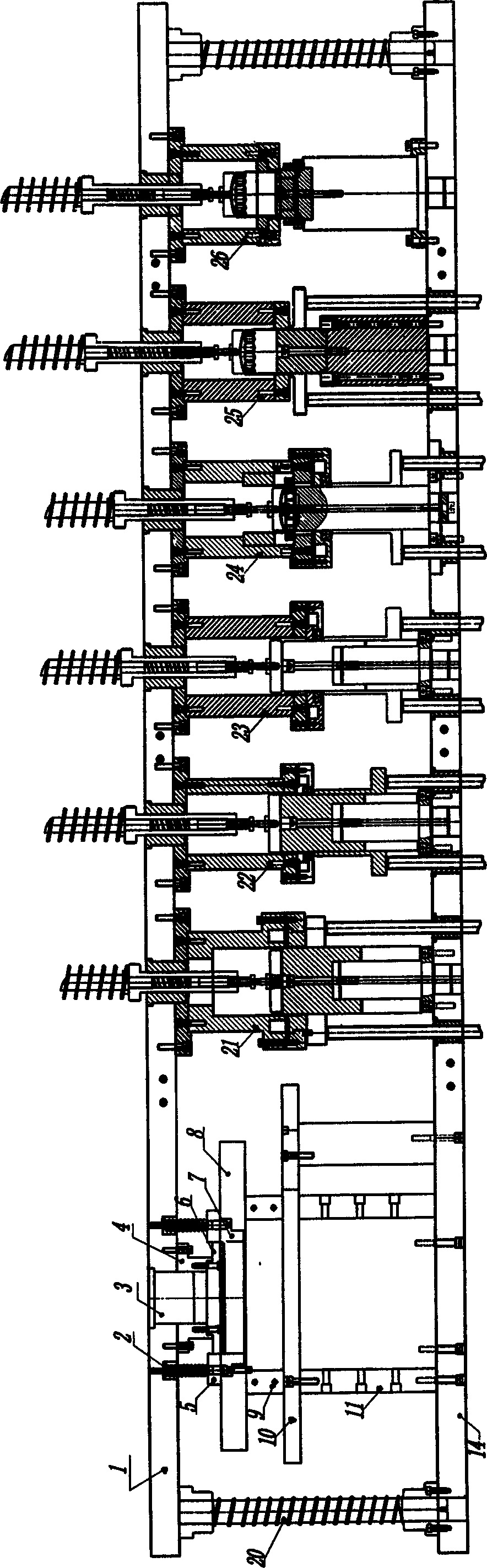

[0008] refer to figure 1 It can be seen that the stretching and blanking device for the filter housing of the present invention comprises an upper template 1 and a lower template 14, on which a lower mold support 11 and a pusher flat plate 10 are mounted, on which a die is mounted. A frame 9, on which the blanking die 7 and the blanking punch 6 are sequentially installed through the die positioning plate 8, and the blanking punch 6 is connected to the upper template 1 through the blanking connection block 4; A blanking positioning block 3 is also installed between the blanking punch 6 and the upper template 1 . It is used for easy exchange of molds and maintenance molds (including blanking punch 6, blanking die 7), more precise matching and material saving and consumption reduction, and blanking convexes of different sizes can be interchanged on a pair of m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com