Vehicle-mounted knife-type antenna cover and precise manufacturing method thereof

A manufacturing method and radome technology, applied to antennas, antenna parts, antennas suitable for movable objects, etc., can solve the problem of affecting the mechanical strength and external dimensions of the radome, not meeting the application requirements of the airborne environment, and not meeting the Tolerance requirements and other issues, to achieve the effect of ensuring appearance quality and dimensional accuracy, reducing product void ratio, and high wave transmission characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] combine Figures 1 to 5 , the present invention will be further described below.

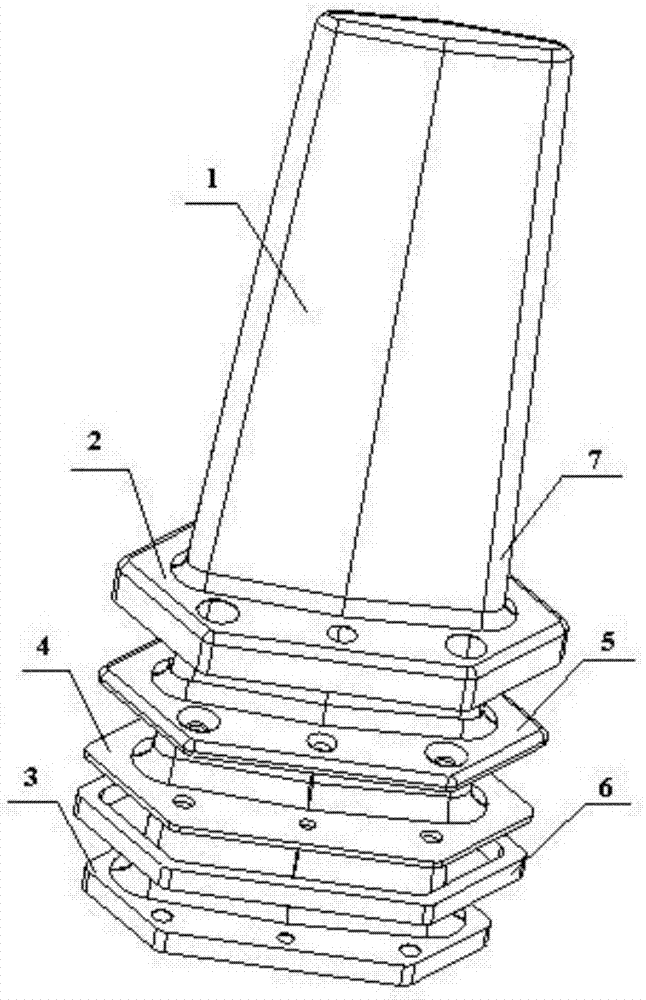

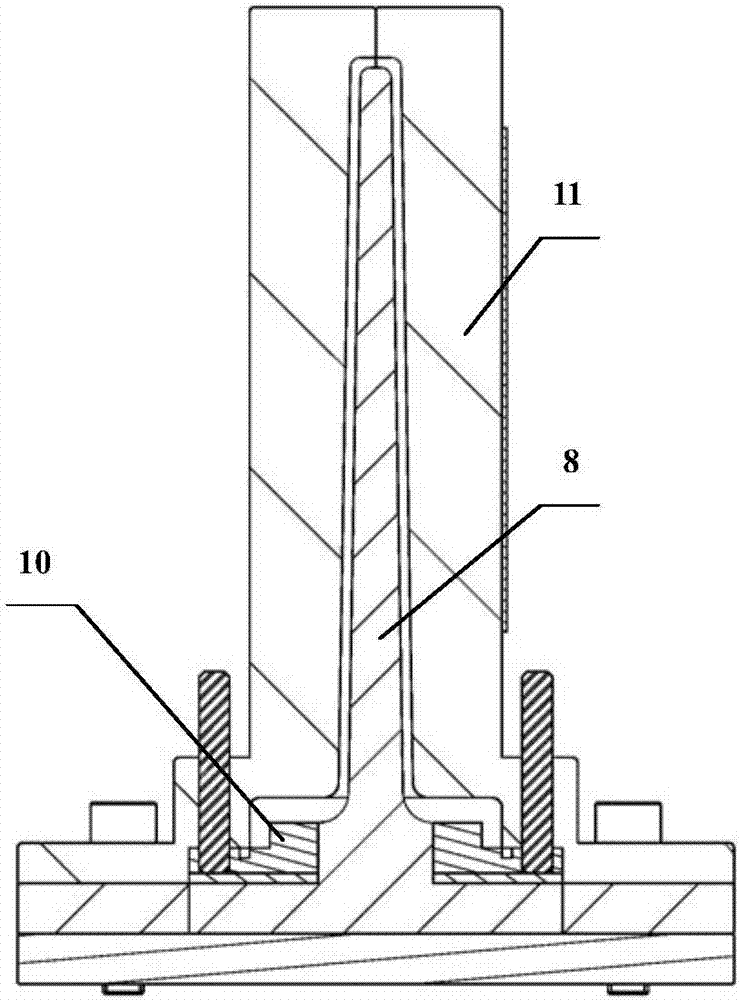

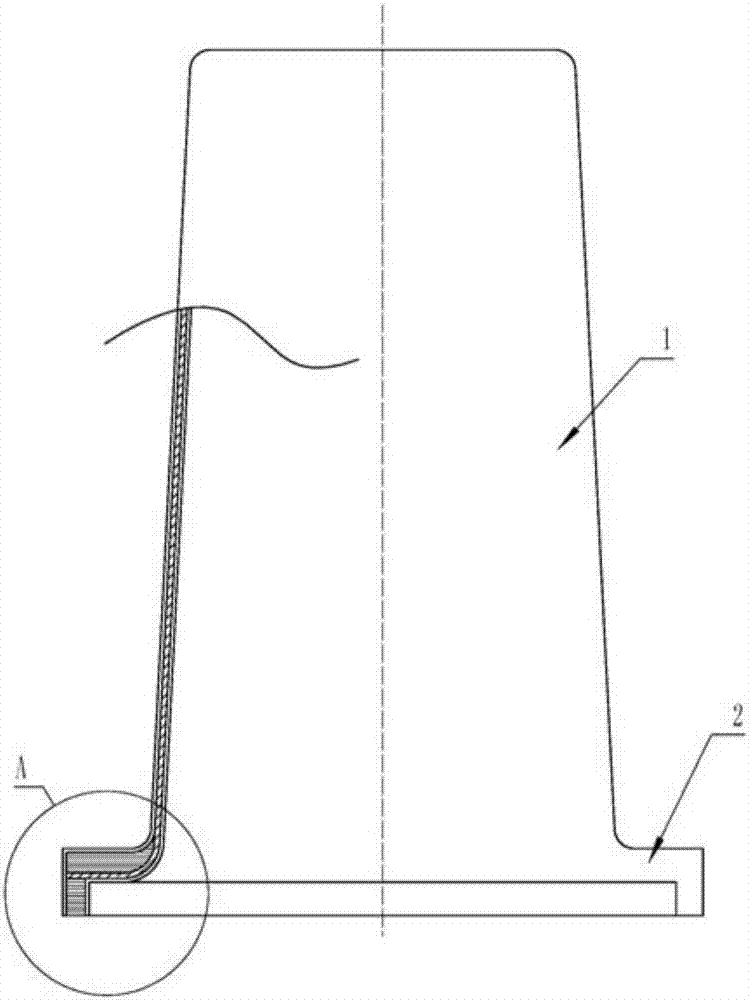

[0036] figure 1 It shows a new type of airborne blade radome of the present invention, including a radome main body, characterized in that: the radome main body includes a horizontally extending assembly area and a vertically extending wave-transmitting area in the center of the assembly area, and the antenna The main body of the cover includes an outer surface layer, a bottom plane layer, a functional layer, and an inner surface layer from outside to inside; The shape of the upper surface of the assembly area and the wave-transmitting area is the same, and a seam layer is provided between the functional layer and the bottom surface of the inner surface layer, and the seam layer has the same shape as the seam of the assembly area of the radome main body, as figure 1 As shown, the inner surface layer 3, the functional layer 4, the bottom plane layer 5, the seam layer 6 and the outer su...

Embodiment 2

[0052] combine Figures 1 to 5 , the present invention will be further described below.

[0053] figure 1 It shows a new type of airborne blade radome of the present invention, including a radome main body, the radome main body includes a horizontally extending assembly part, and it is characterized in that: the radome main body sequentially includes The outer surface layer 7, the functional layer 4 and the inner surface layer 3; the bottom edge of the functional layer 4 is connected to the inner wall of the assembly part of the outer surface layer 7, and a cavity is isolated between the functional layer 4 and the outer surface layer 7, and in the cavity Filled with a bottom plane layer 5, located below the functional layer 4, a seam layer is provided between the outer surface layer 7 and the inner surface layer 3, the seam layer 6 has the same shape as the mouth of the assembly area of the radome main body, and the inner surface layer 3. The bottom plane layer 5, the seam...

Embodiment 3

[0068] combine Figures 1 to 5 , the present invention will be further described below.

[0069] figure 1 It shows a new type of airborne blade radome of the present invention, including a radome main body, the radome main body includes a horizontally extending assembly part, and it is characterized in that: the radome main body sequentially includes The outer surface layer 7, the functional layer 4 and the inner surface layer 3; the bottom edge of the functional layer 4 is connected to the inner wall of the assembly part of the outer surface layer 7, and a cavity is isolated between the functional layer 4 and the outer surface layer 7, and in the cavity The inside is filled with a bottom plane layer 5, and a seam layer is provided between the outer surface layer 7 and the inner surface layer 3 under the functional layer 4. The seam layer 6 has the same shape as the seam of the assembly area of the radome main body. Embodiment The inner surface layer 3, the bottom plane la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com