Device and method for self-piercing riveting of half-hole rivet loaded by pulse magnet field force

A pulsed magnetic field and self-piercing riveting technology, applied in the field of self-piercing riveting devices for semi-hole rivets, can solve the problems of difficult automation, complex riveting process, poor riveting quality, etc., and achieve full-position operation, automatic and semi-automatic production, The effect of stable riveting quality, improving strength and fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

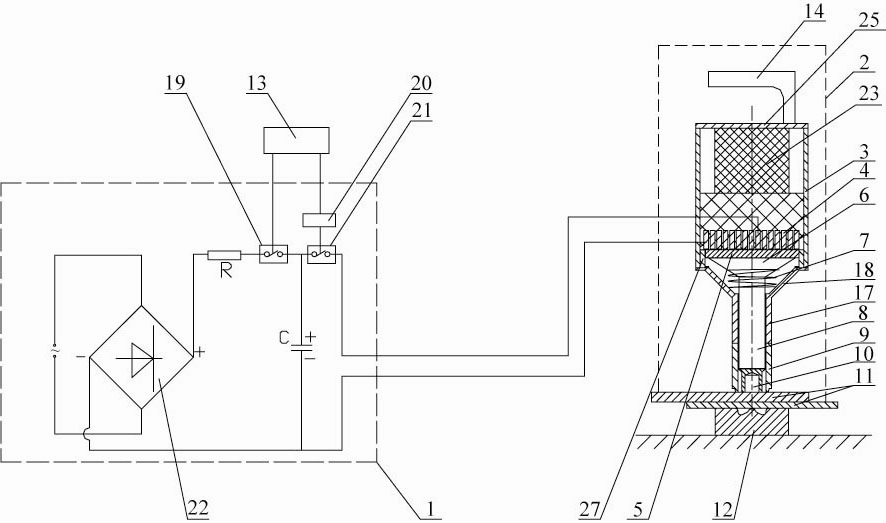

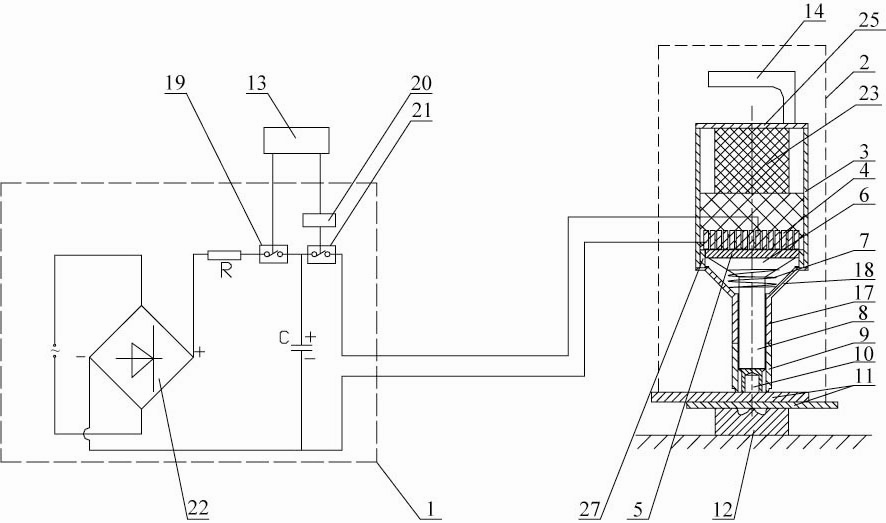

[0009] Specific implementation mode one: combine figure 1 Describe this embodiment mode, a kind of half-hole rivet self-piercing riveting device that utilizes the pulse magnetic force loading of this embodiment to be made up of electromagnetic riveting gun 2, die 12, low-voltage electromagnetic riveting device 1 and control box 13; Electromagnetic riveting gun 2 is made up of The primary coil 4, the driving plate 5, the stress wave modulator 6, the compression spring 7, the punch 8, the electromagnetic riveting gun handle 14, the shock absorber 23, the positioning ring 27 and the riveting gun shell; Axially through the cavity, the shell of the riveting gun is composed of a large cylindrical tube 3 with a large outer diameter, a front cover, a rear cover 25 and a fastening sleeve 9, and the front cover is composed of a frustum-shaped tube 18 and a punch guide tube 17. The handle 14 of the electromagnetic riveting gun is fixedly connected with the back cover 25, and the punch gu...

specific Embodiment approach 2

[0010] Specific implementation mode two: combination figure 1 Describe the present embodiment, the low-voltage electromagnetic riveting device 1 of the present embodiment is made up of electromagnetic riveting charging switch 19, capacitor group C, current limiting resistor R, rectifier 22, high-frequency thyristor discharge switch 21 and high-voltage pulse generator 20; terminals are respectively connected to the two AC voltage input terminals of the rectifier 22, the DC voltage positive output terminal of the rectifier 22 is connected to one end of the current limiting resistor R, and the other end of the current limiting resistor R is connected to one end of the electromagnetic riveting charging switch 19, and the electromagnetic riveting The other end of the charging switch 19 is respectively connected with one end of the high-frequency thyristor discharge switch 21 and the positive end of the capacitor bank C, the other end of the high-frequency thyristor discharge switch ...

specific Embodiment approach 3

[0011] Specific implementation mode three: combination figure 1 The present embodiment will be described. The shock absorber 23 of the present embodiment is a shock absorber spring, rubber or rubber spring. Select as needed. Others are the same as the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com