Brand new PCB automatic riveting machine

A riveting machine, automatic technology, applied in the field of riveting machines, to achieve the effect of high reliability, less manual labor, and high riveting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

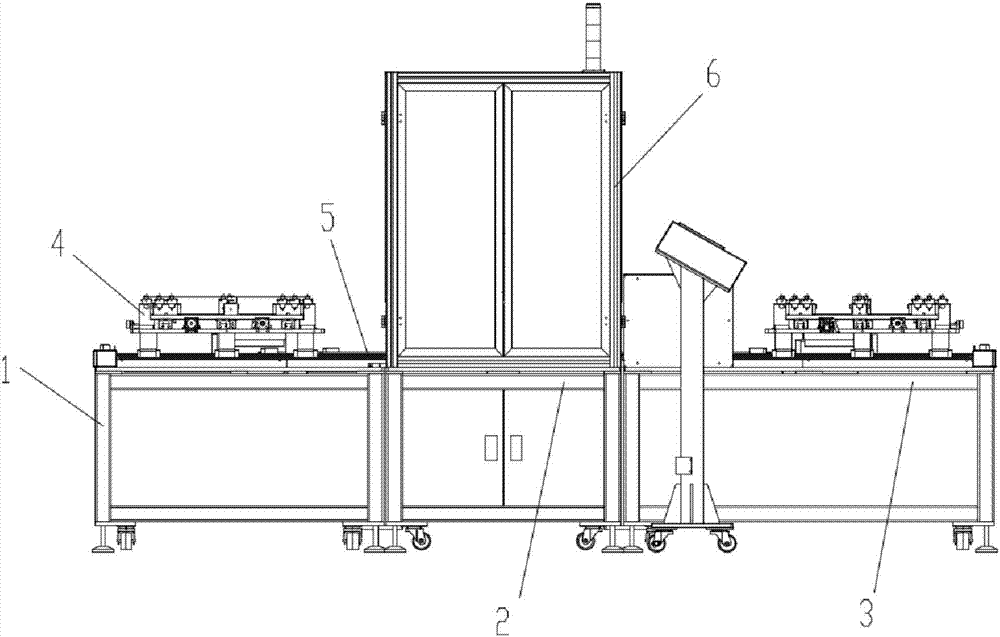

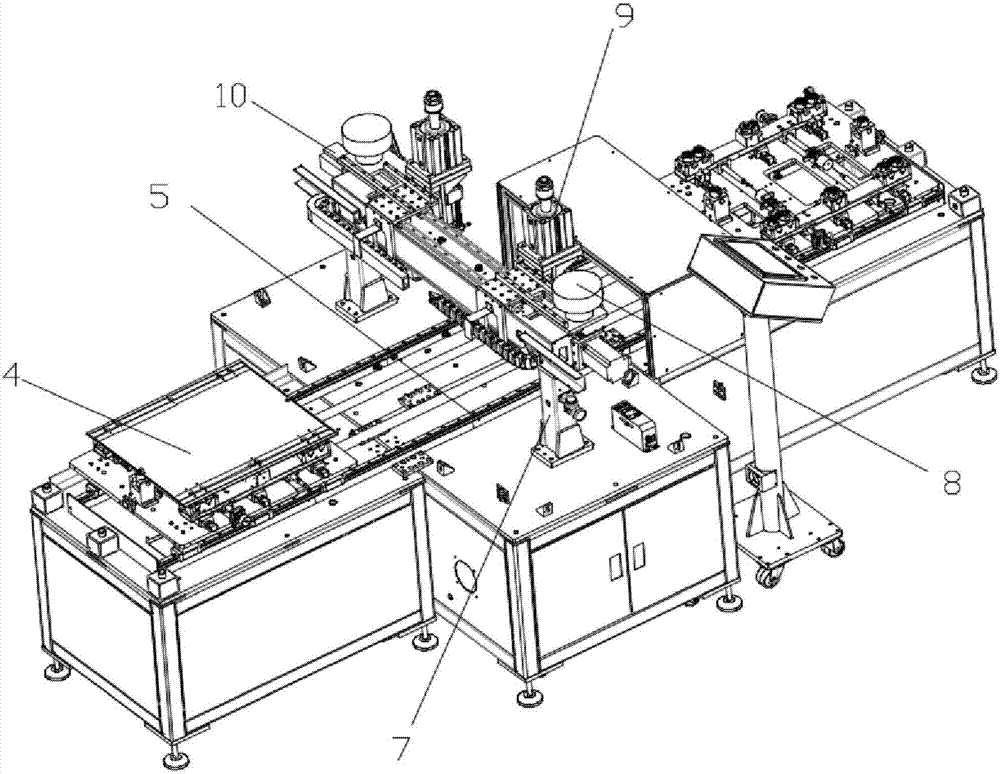

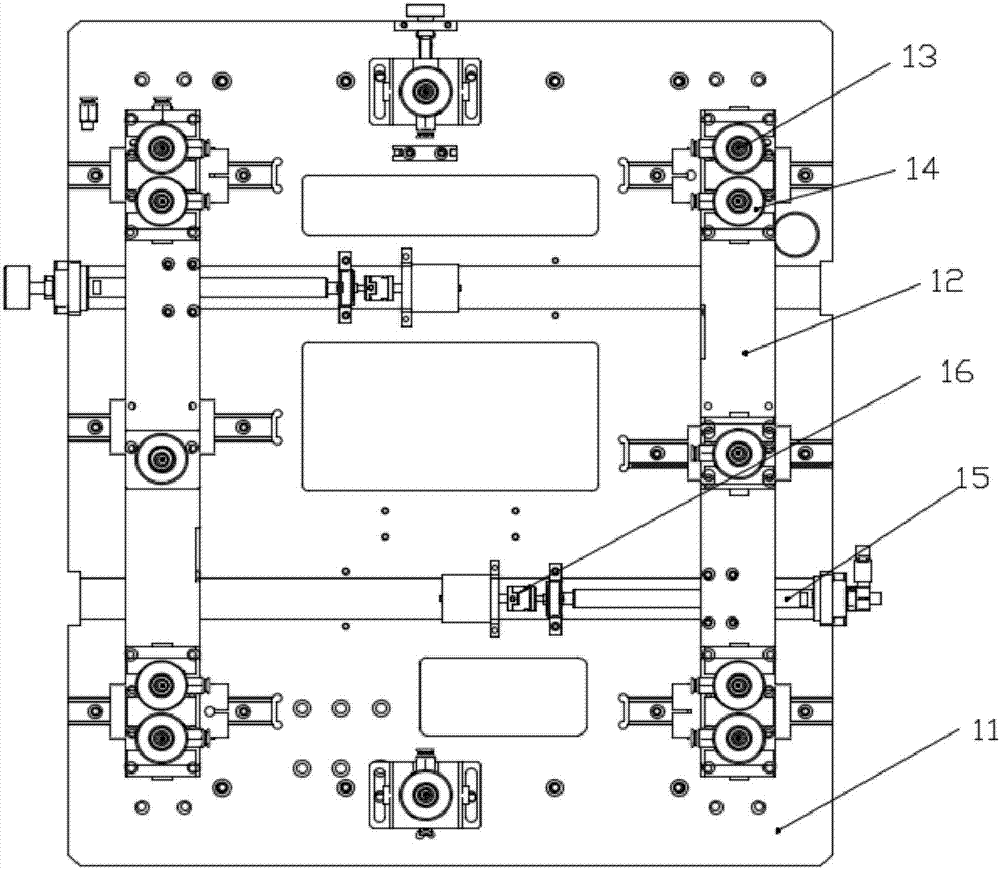

[0025] Such as figure 1 , figure 2 with image 3 A kind of brand-new PCB automatic riveting machine shown, comprises frame, feeding mechanism, protective cover 6 and riveting mechanism, and described frame is made up of the first frame 1, the second frame 2 and the third frame 3 are connected sequentially from left to right. The feeding mechanism includes two feeding fixtures 4 and a feeding guide rail 5. The feeding guide rail 5 is arranged on the first frame 1, the second frame 2 and the On the third frame 3, each of the feeding rails 5 above the first frame 1 and the third frame 3 is movably connected with a feeding jig 4, and the feeding jig 4 includes a fixed Bottom plate 11, adjusting bottom plate 12, floating needle 13, floating needle fixing jig 14 and adjusting screw rod 15, described fixed base plate 11 is movably connected on the feeding guide rail 5, and described adjusting screw rod 15 is arranged on the fixed On the base plate 11, the adjusting base plate 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com