Rivet punching die

A technology for pressing rivets and dies, which is applied in the field of riveting dies. It can solve the problems of affecting riveting quality, bending deformation of the overhanging part of the die, and breaking of the die, so as to improve the quality of riveting, prolong the service life and ensure smoothness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

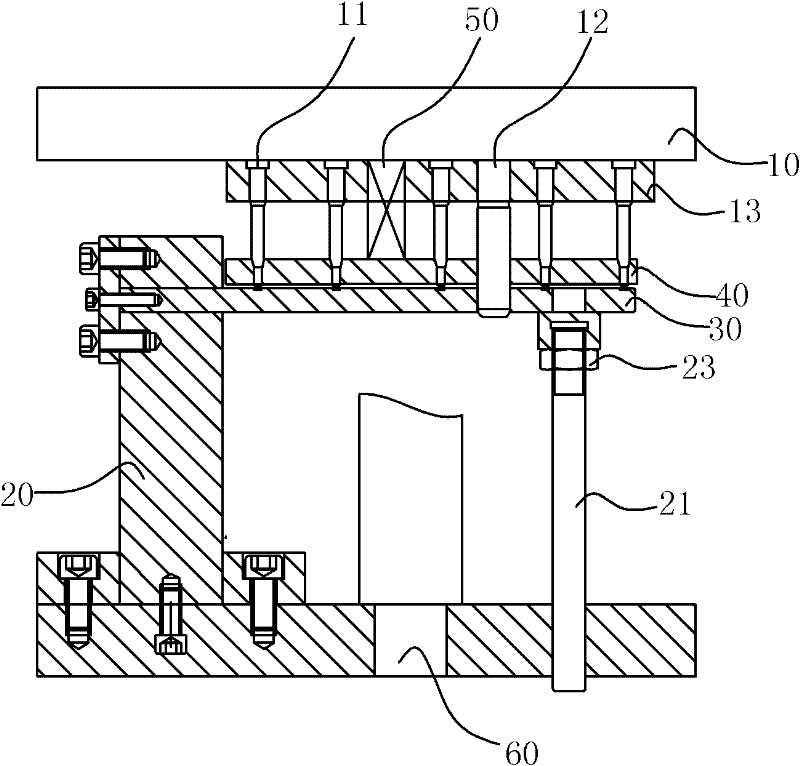

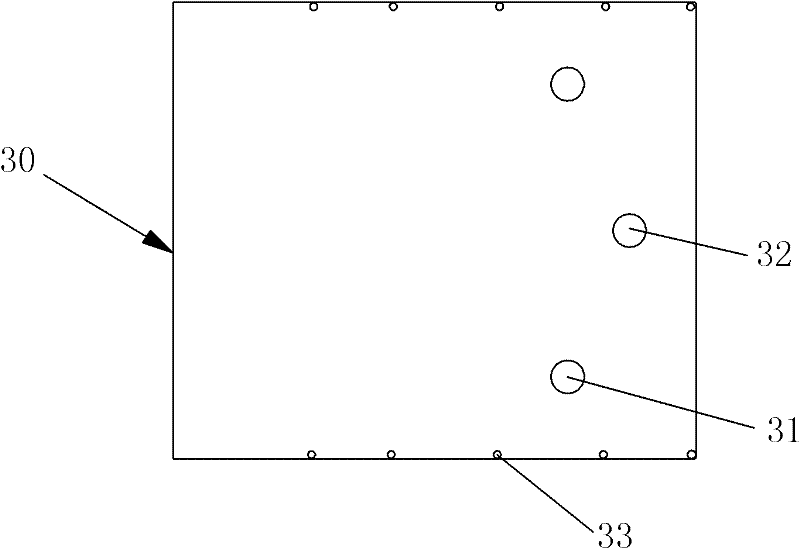

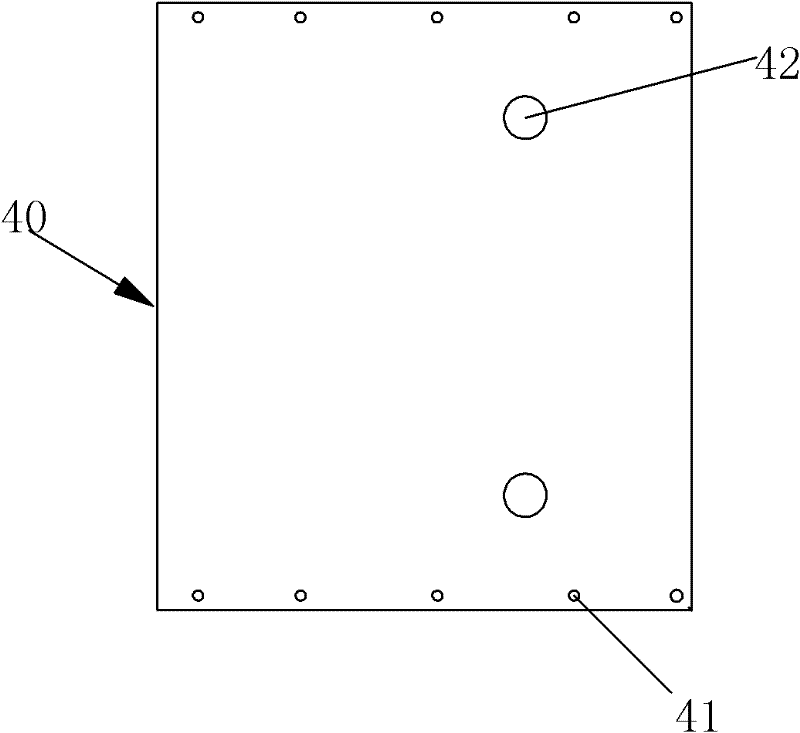

[0013] A kind of rivet pressing mold, comprises the upper template 10 is provided with the riveting punch 11, the overhanging die 30 is fixedly connected on the support 20, is provided with the spring 50 between the binder plate 40 and the upper template 10, the upper template 10 and the support 20 are provided with a guide mechanism 60, the riveting punch 11 passes through the binder plate 40 and its head forms a stamping fit with the die 30, and the overhanging part of the die 30 is provided with a support mechanism. One end of the die 30 is fixedly connected to the bracket 20 and the other end is overhanging. The workpiece to be processed is set on the die 30. The riveting punch 11 passes through the binder plate 40 and then punches the rivet to realize riveting. Among them, under the action of the supporting mechanism, the overhanging part of the die 30 offsets most of the stamping force, effectively prevents the die from being deformed, improves the quality of riveting, en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com