Wire harness sheet metal riveting equipment and use control method

A control method and sheet metal technology, applied in the field of wire harness sheet metal riveting, can solve the problems of high labor intensity and unqualified products in wire harness sheet metal riveting, and achieve the effects of reliable riveting quality, simple use and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

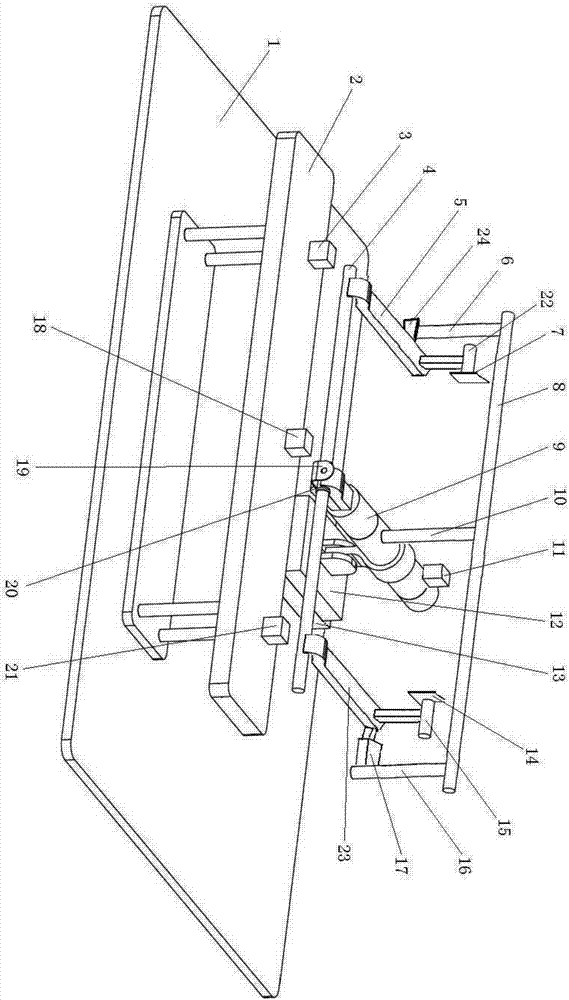

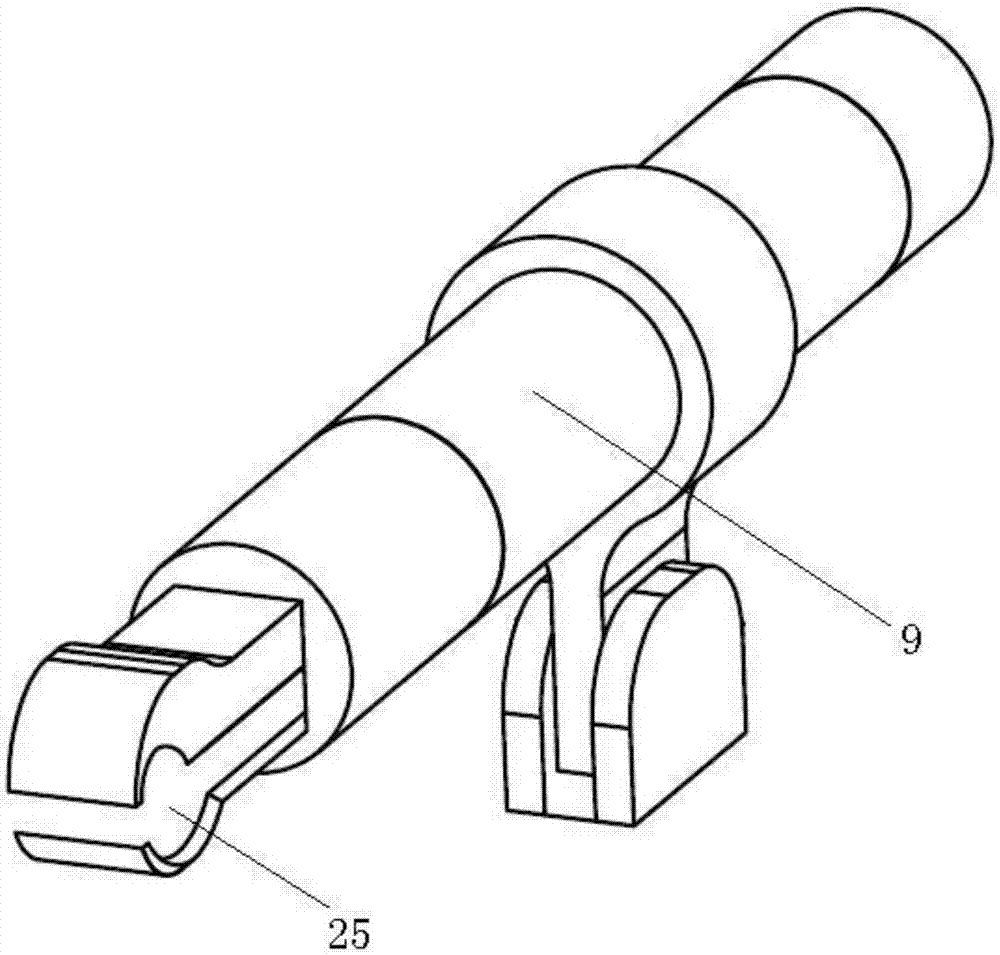

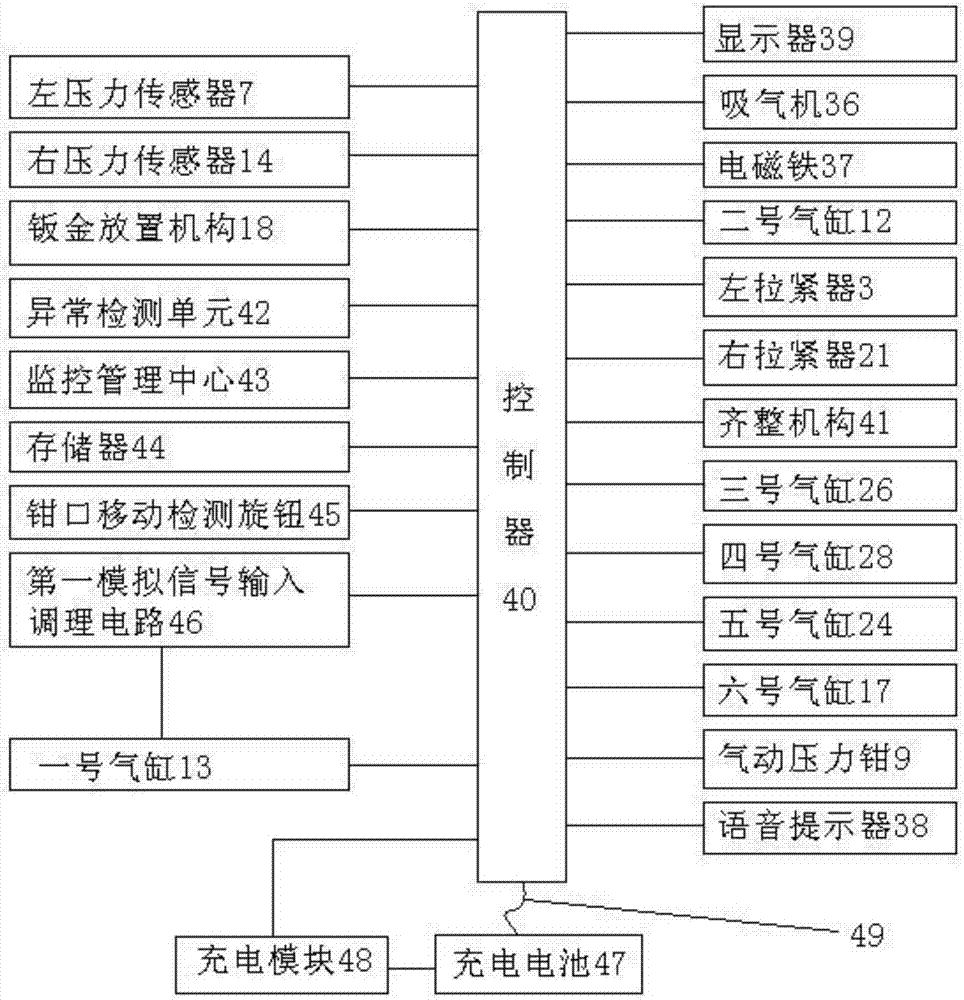

[0024] Example 1: Wire harness sheet metal riveting equipment, see figure 1 , figure 2 , image 3 , Image 6 As shown, it includes a platform 1 and a controller 40, as well as a voice prompt 38 and a display 39 respectively connected to the controller. The No. 1 cylinder 13 is fixed on the platform, and the No. 1 telescopic rod of the No. 1 cylinder is arranged to move horizontally back and forth; No. 2 cylinder 12 is fixed on the No. 1 telescopic rod of the No. 1 cylinder, and the No. 2 telescopic rod of the No. 2 cylinder is arranged vertically up and down; the No. 2 telescopic rod of the No. 2 cylinder is fixed horizontally and forwards. Pneumatic pressure pliers 9 and the jaws 25 of the pneumatic pressure pliers are arranged forward; on the platform in front of the jaws of the pneumatic pressure pliers, there is a tooling fixing table 2; the left and right ends of the tooling fixing table are respectively provided with a wire harness capable of tensioning The left tensione...

Embodiment 2

[0026] Example 2, see figure 1 , figure 2 , image 3 , Figure 4 As shown, the difference between Embodiment 2 and Embodiment 1 lies in. A sheet metal placing mechanism 18 is provided on the tooling fixed platform between the left tensioner and the right tensioner, and the sheet metal placing mechanism is arranged on the tooling fixed platform directly in front of the jaws. The control end of the sheet metal placing mechanism is connected with The controller is connected; the sheet metal placement mechanism includes the No. 3 cylinder 26 fixedly arranged on the tooling fixing table, the No. 4 cylinder 28 fixedly arranged on the No. 3 telescopic rod 27 of the No. 3 cylinder, and the No. 4 cylinder fixedly arranged on the No. 4 cylinder The sheet metal placer on the telescopic rod 29, and the third telescopic rod of the third cylinder is arranged vertically upwards, the fourth telescopic rod of the fourth cylinder is arranged toward the jaws of the pneumatic pressure clamp, and t...

Embodiment 3

[0028] Example 3, see figure 1 , figure 2 , image 3 , Figure 5 As shown, the difference between Embodiment 3 and Embodiment 2 lies in. The sheet metal placer includes an electromagnet 37, hanging nails and an "L"-shaped placing block fixedly arranged on the No. 4 telescopic rod. The placing block includes a vertical block arranged vertically and a horizontal block arranged horizontally. The hanging nails are set On the vertical block on the side of the horizontal block, the electromagnet is arranged on the horizontal block, and the control end of the electromagnet is connected with the controller.

[0029] When the embodiment 3 is in use, its use control method is as follows: the user first clamps the two ends of a wire harness covered with a sheath and sheet metal on the sheath to the left tensioner and the right tensioner. Use the mounting holes on the sheet metal to hang the sheet metal on the pegs of the sheet metal placer; then under the command of the controller, start t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com