Riveting machine

A technology for riveting machines and riveting punches, applied in metal processing equipment, feeding devices, positioning devices, etc., can solve the problems of low degree of automation, unstable riveting quality, cumbersome operation process, etc., and achieve low labor intensity and consistent Good performance, simple and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

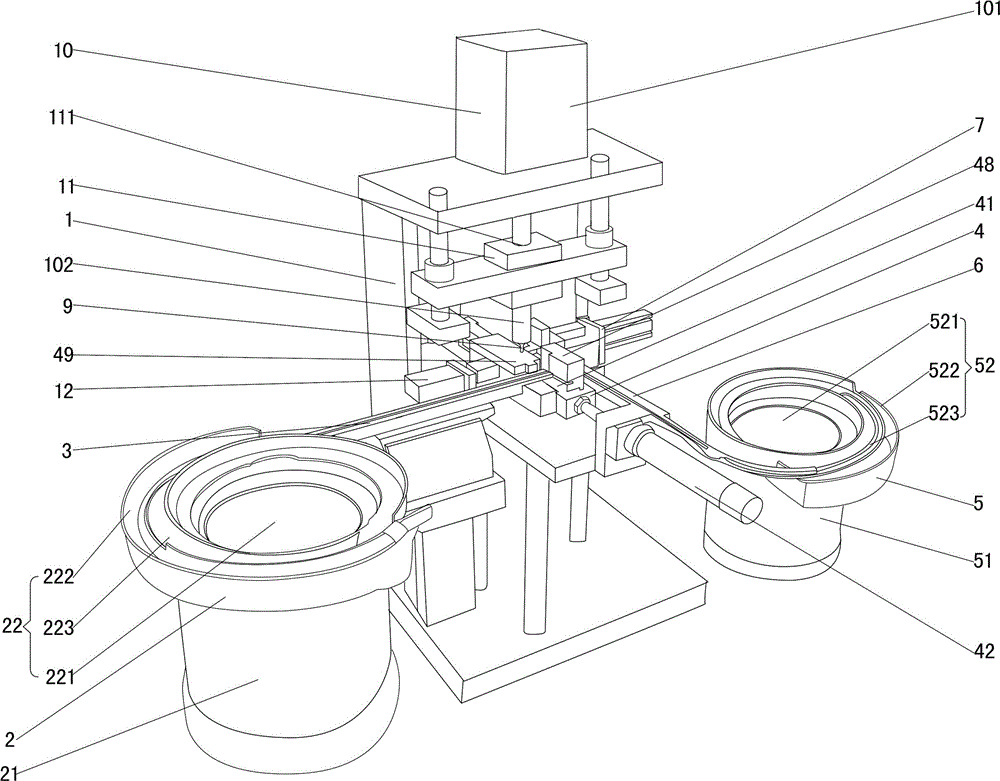

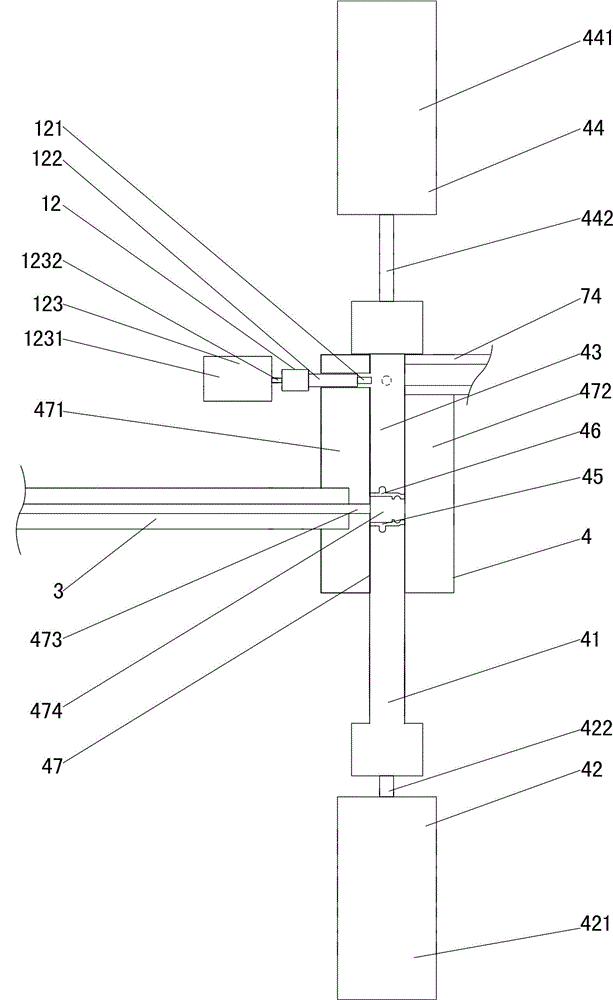

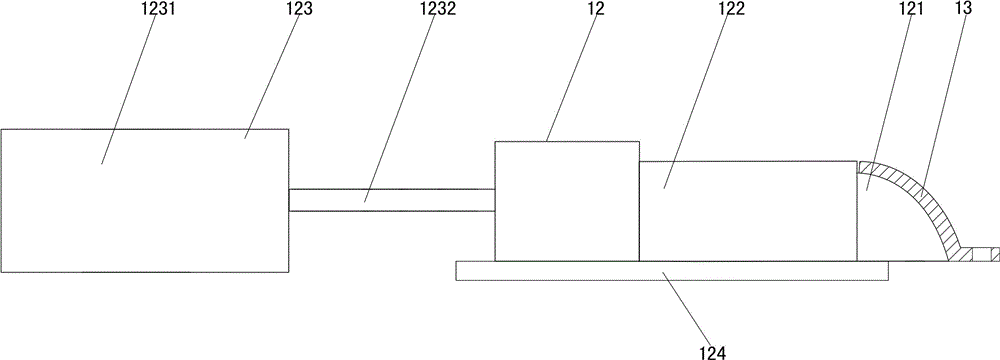

[0021] Such as figure 1 - Figure 5 As shown, this riveting machine includes a frame 1, a metal sheet vibration plate 2, a metal sheet output track 3, a metal sheet clamping and translation mechanism 4, a contact vibration plate 5, a contact output track 6, and a contact translation mechanism 7 , contact jacking mechanism 8, riveting punch 9, riveting punch lifting control mechanism and receiving chute; metal sheet vibrating plate 2 includes first vibrating drive device 21 and first disc body 22, first disc body 22 is installed On the first vibration driving device 21, the first disc body 22 includes a first disc bottom 221 and a first disc side wall 222, and a first spiral rising track 223 is provided on the inner side of the first disc side wall 222; the sheet metal output track 3 Installed on the frame 1, the metal sheet output track 3 is fixedly connected to the first disc body 22, and the inlet end of the metal sheet output track 3 is connected to the end of the first sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com