Riveting pressing forming device for cover plate of automobile clutch booster

A clutch and booster technology, which is applied in the field of riveting forming devices between the cover plate and the main body of the automobile clutch booster, which can solve the problems of fracture of the riveting part of the clutch booster, short service life of the clutch booster, corrosion resistance and weather resistance Poor performance and other problems, to achieve the effect of changing the molding characteristics, improving the characteristics of corrosion resistance and weather resistance, and good riveting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

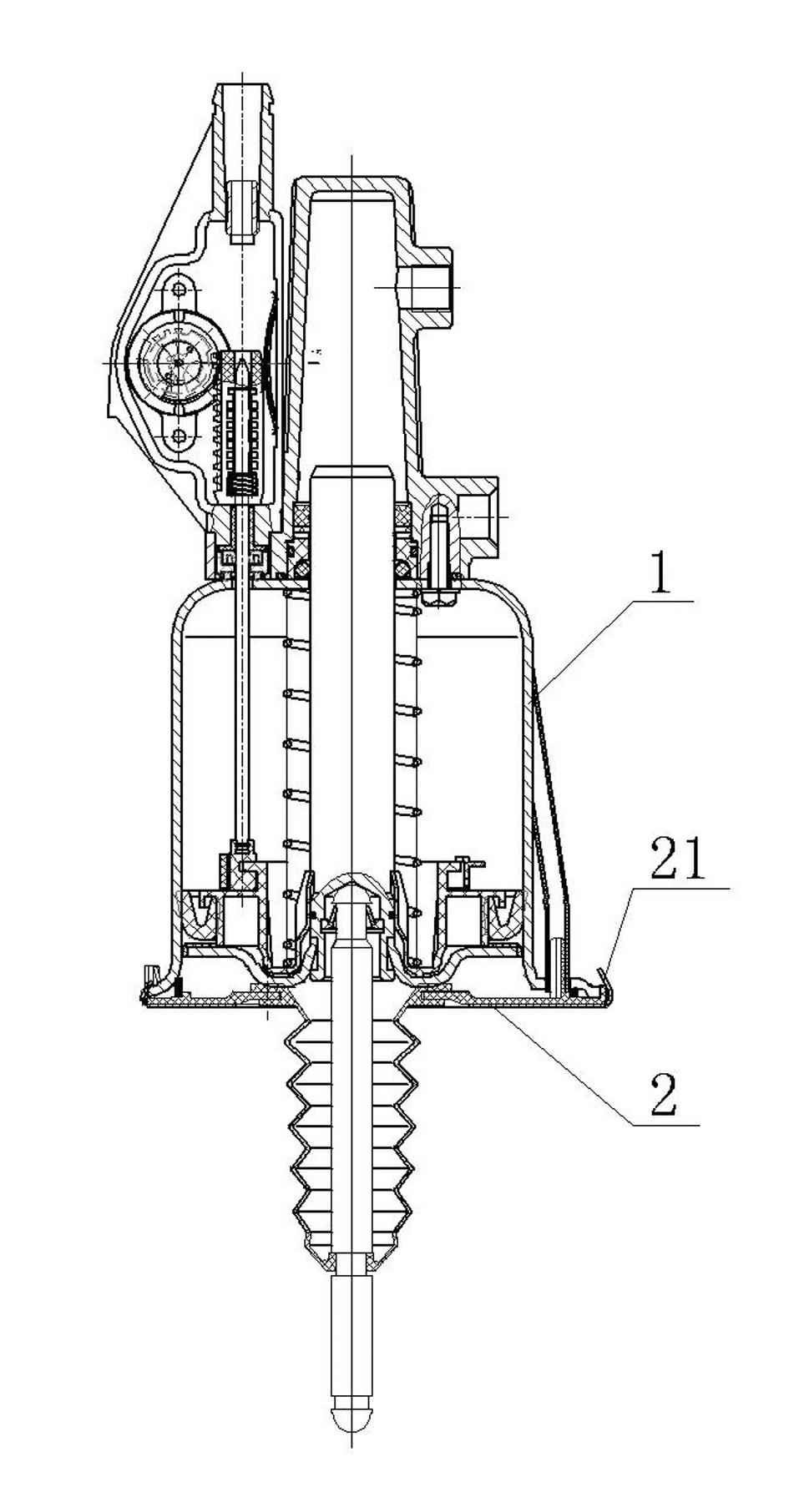

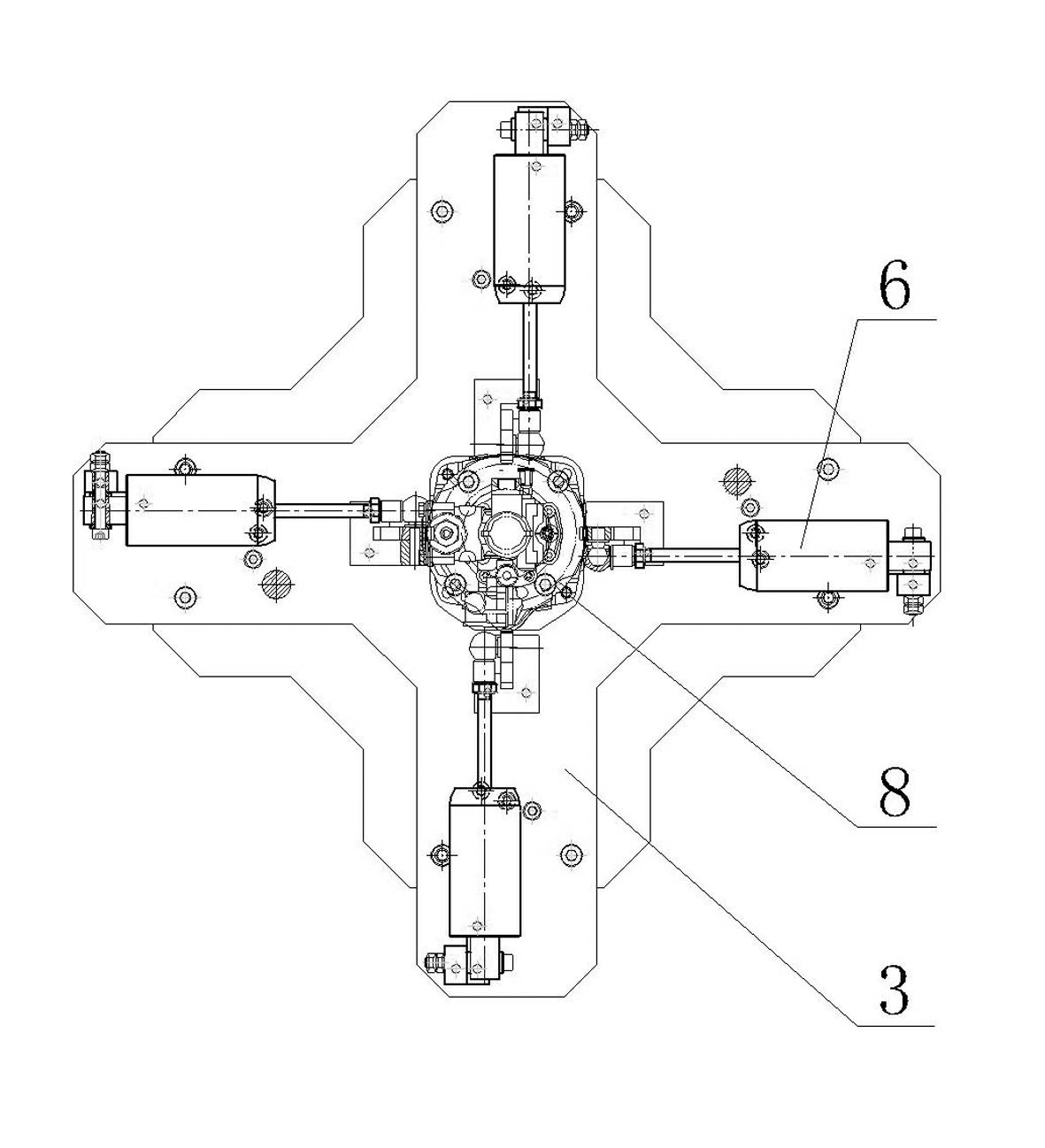

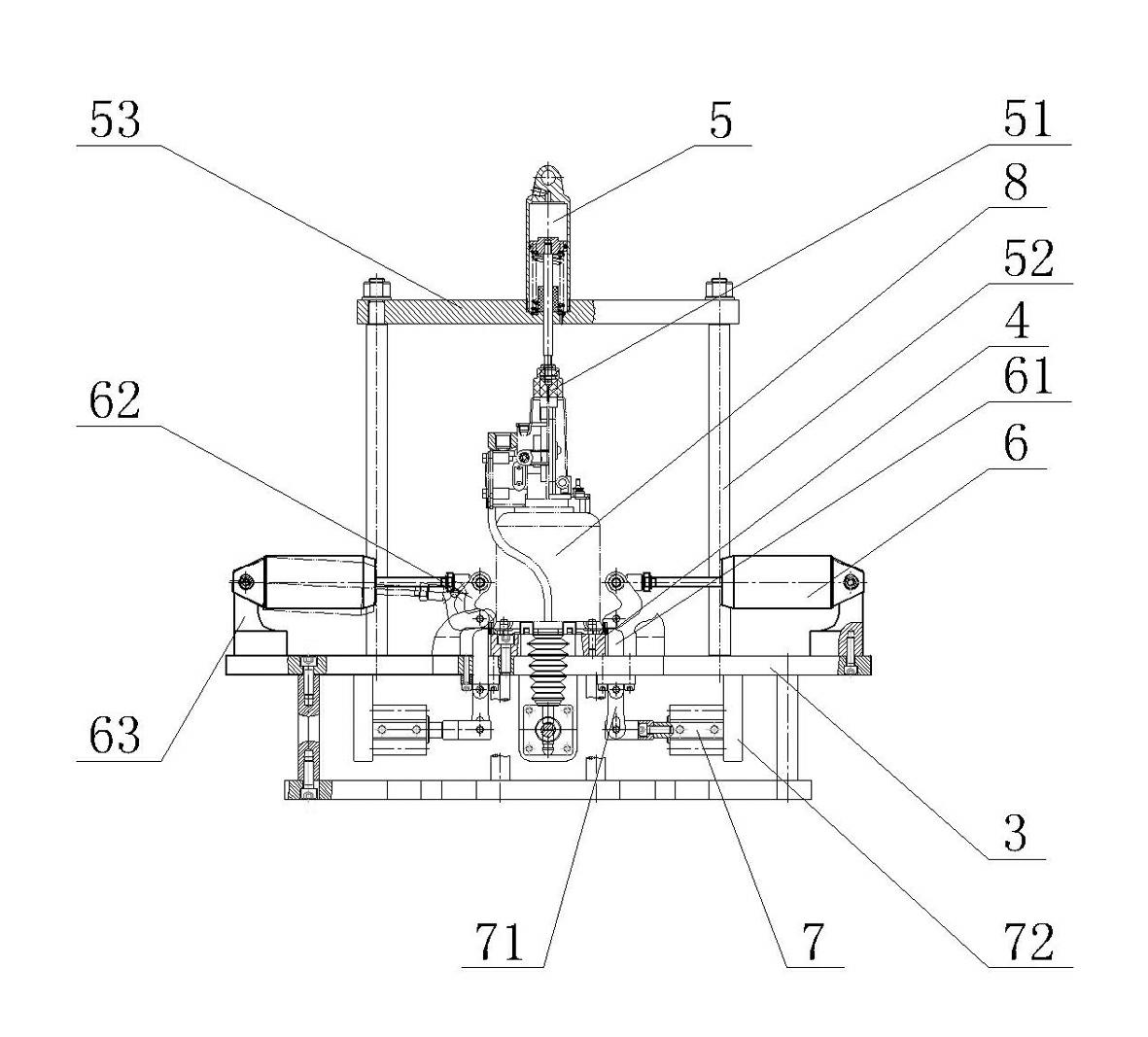

[0020] Such as figure 2 , image 3 and Figure 4 , combined with figure 1 As shown, an automobile clutch booster cover plate riveting forming device includes a base plate 3, a positioning seat 4 is provided on the base plate 3, a positioning cylinder 5 is provided on the positioning seat 4, and a pressing block 51 is provided on the positioning cylinder 5 , the base plate 3 is provided with a column 52, the top of the column 52 is fixed with a support plate 53, the positioning cylinder 5 is installed on the support plate 53, the base plate 3 is provided with four riveting cylinders 6, and the output end of the riveting cylinder 6 is connected with a riveting Assemblies, the base plate 3 of the corresponding riveting cylinder 6 is provided with a compression cylinder 7, and the output end of the compression cylinder 7 is connected with a compression assembly. Riveting components such as Figure 4 As shown, it includes a mounting seat 61 and a hinged indenter 62, the mounti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com