Method and system for self-locking and fixedly connecting thin plate

A connection method and connection system technology, which is applied in the field of thin plate self-locking fastening connection and system, can solve the problem of light weight thin plate connection, optimize fastening connection and other problems, and achieve improved process safety, stable riveting quality, and simple processing procedures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The thin plate self-locking fastening connection method in this embodiment includes the following steps:

[0024] The first step: make the following sheet self-locking fastening connection system:

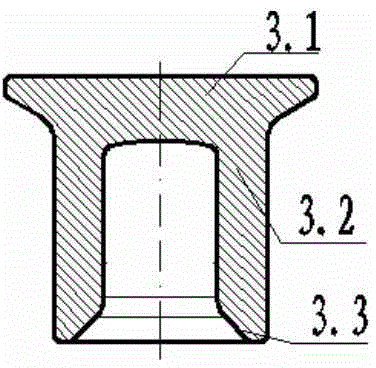

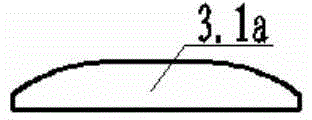

[0025] See figure 2 , a self-locking rivet 3 consisting of a head 3.1 and a shank 3.2 is set, the shank is a cylinder with a polished surface on the outside, the front end of the inner hole of the cylinder is a pointed ring 3.3, and the head 3.1 is a countersunk head. See image 3 , the head 3.1a is a flat head.

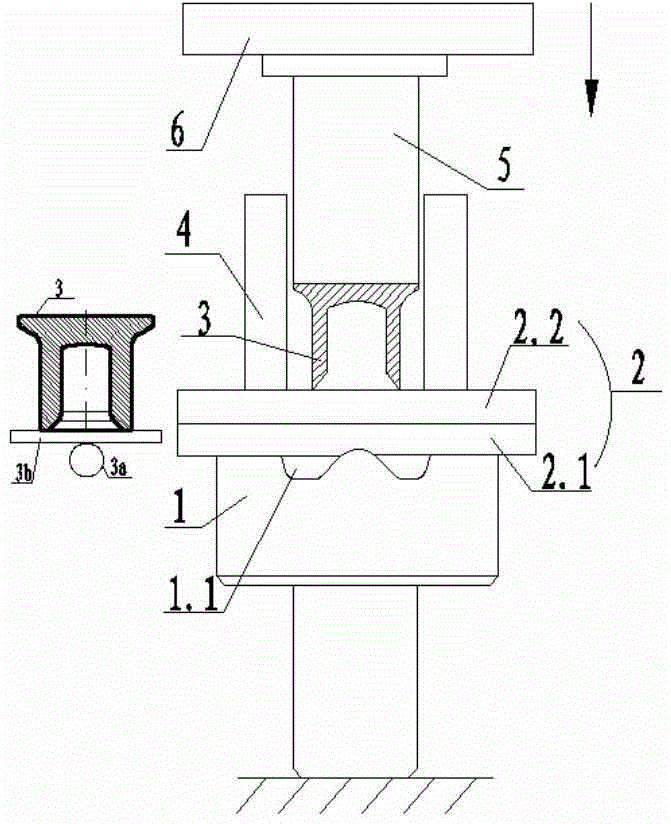

[0026] See figure 1 , When connecting, set the cylindrical blank holder 4 outside the self-locking rivet 3; and set the die 1 placed under the connected thin plate 2, and there is a ring groove 1.1 above the die. It is provided that a hammer 5 is applied to the self-locking rivet and driven by a self-locking riveting tool 6, and a blank holder 4 is set on the outer circle of the hammer, and there is a transitional fit between the two.

[0027] See figure 1 ,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com