Barrel assembly for a rivet gun

a rivet gun and barrel assembly technology, applied in metal-working equipment, metal-working equipment, manufacturing tools, etc., can solve the problem of meaningless consumption of high-pressure air, and achieve the effect of reducing high-pressure air consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

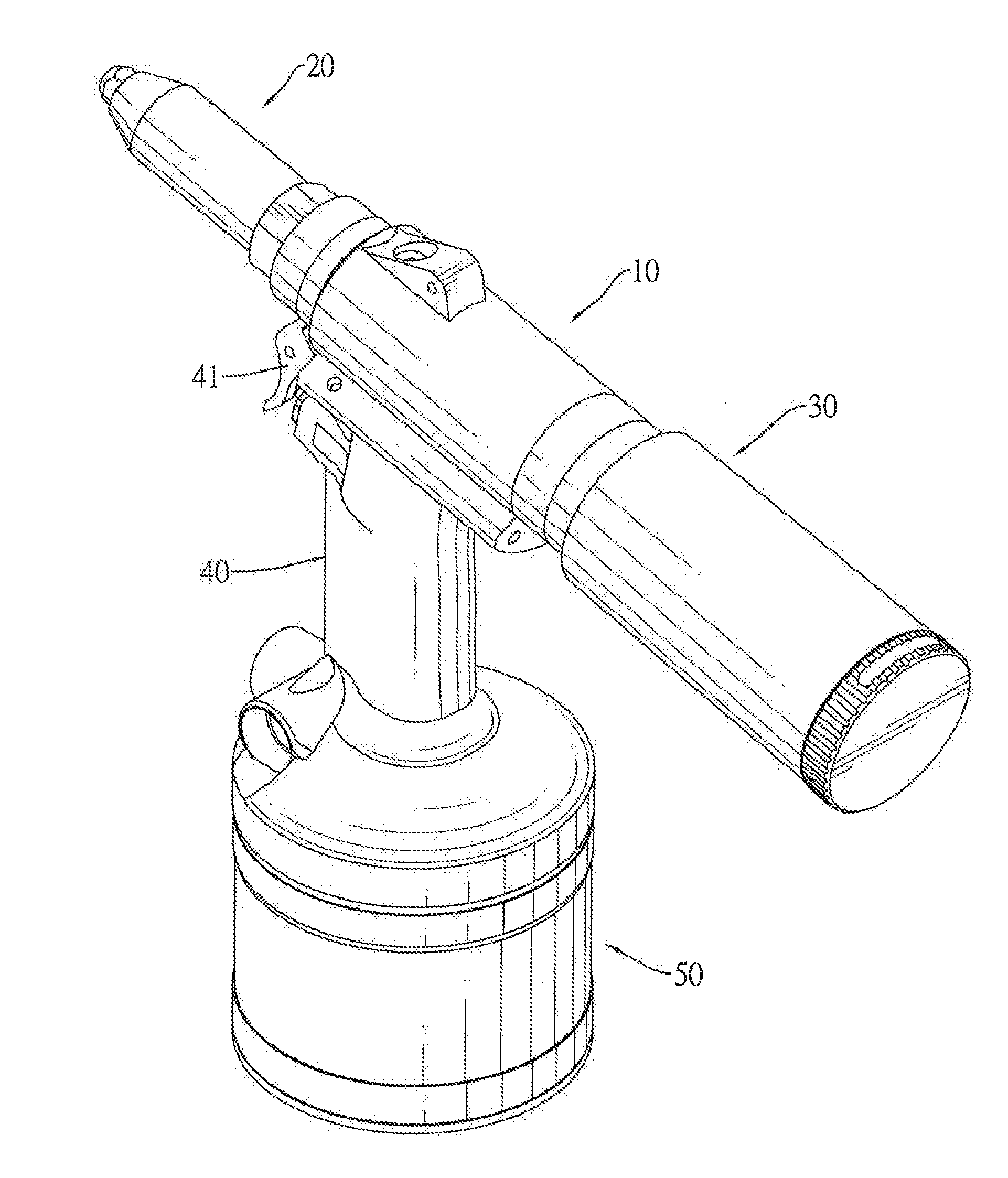

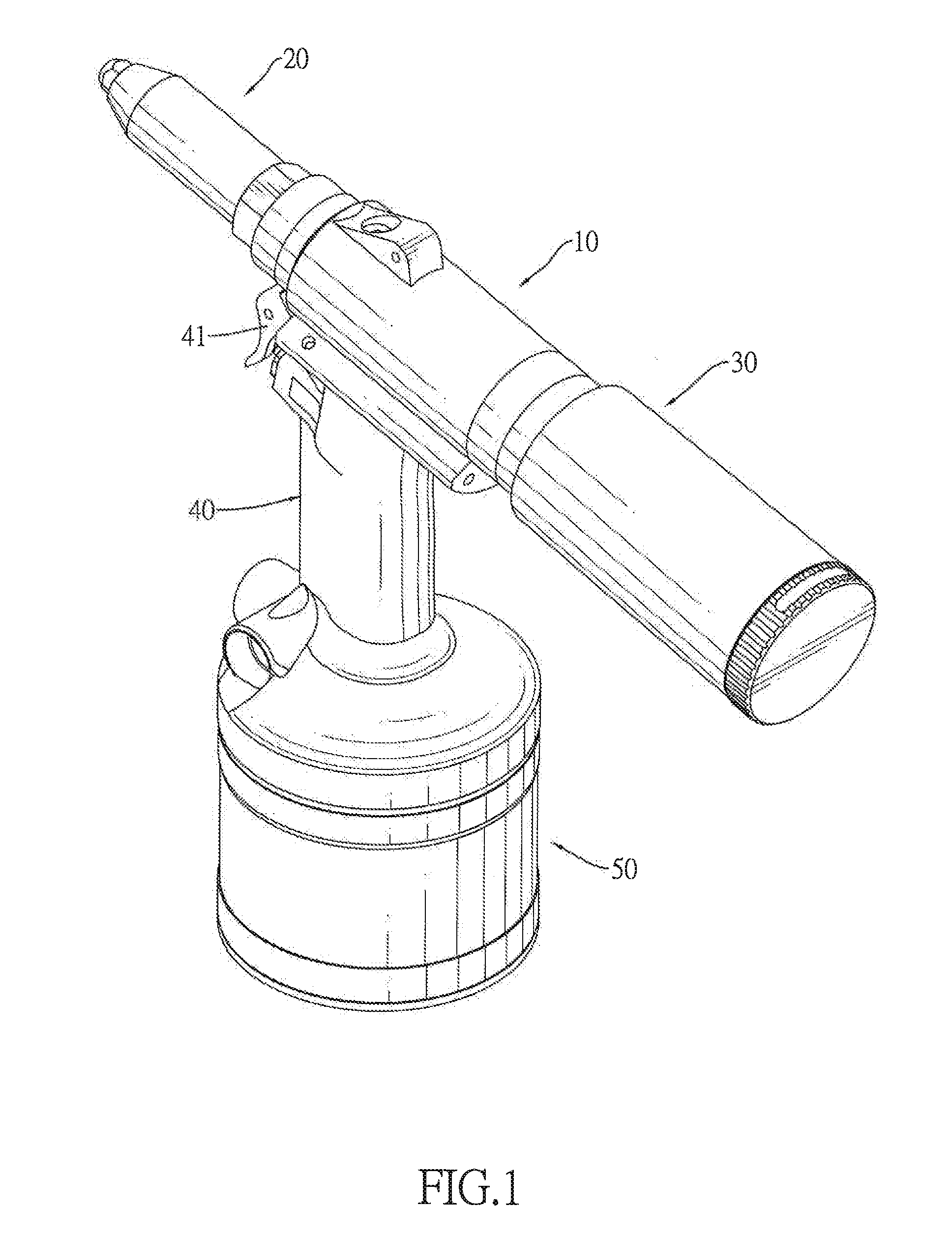

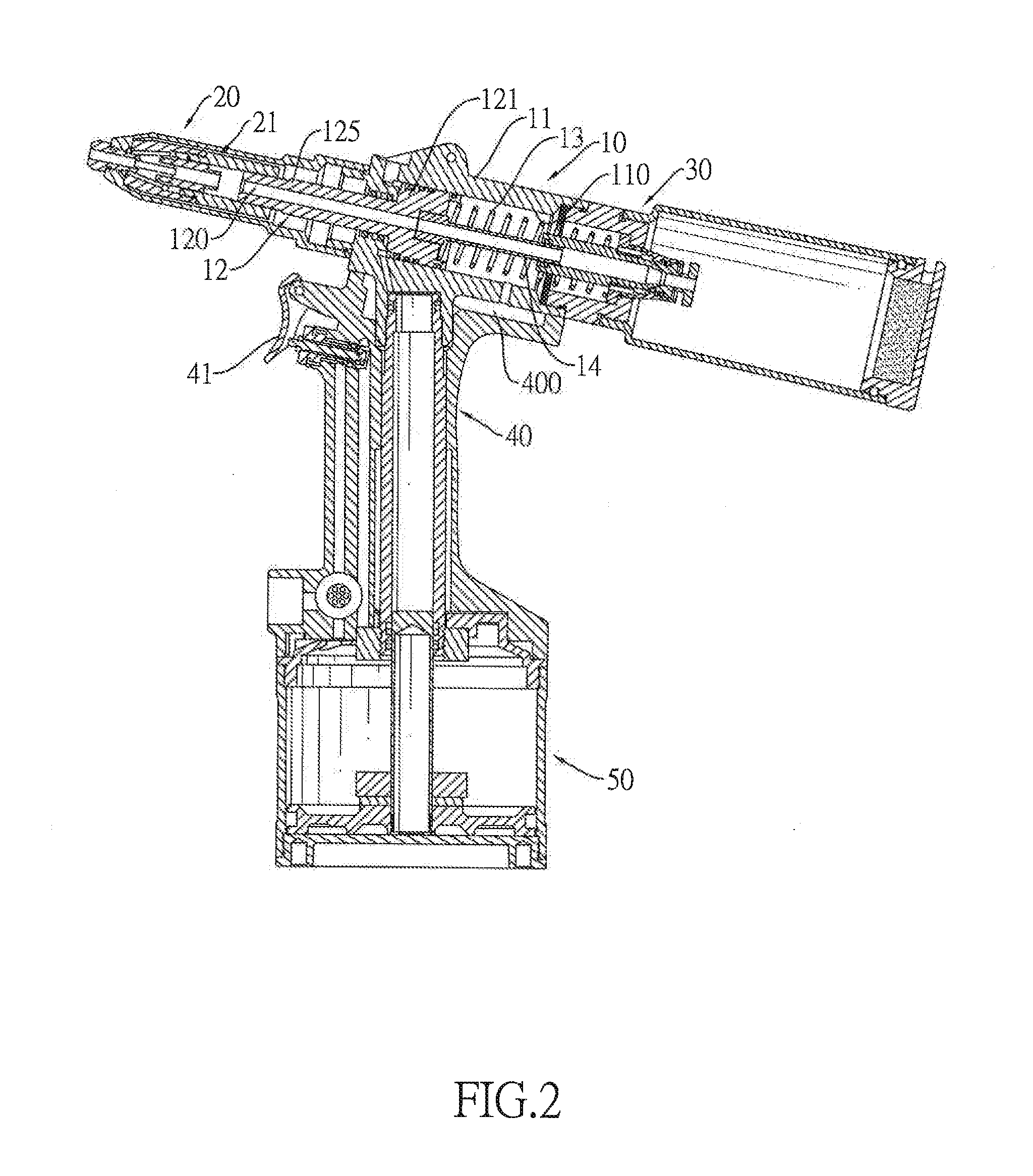

[0021]With reference to FIGS. 1 and 2, a barrel assembly 10 in accordance with the present invention may be assembled with a handle 40 and a pneumatic cylinder 50 into a complete rivet gun. The handle 40 has a mounting slot 400 and trigger 41 for driving the rivet gun to pull a rivet. The pneumatic cylinder 50 may be connected to a high pressure source to output high pressure air into the barrel assembly 10.

[0022]With further reference FIGS. 3 to 6, the barrel assembly 10 may be mounted on the mounting slot 400 of the handle 40 and comprises a tube body 11, a vising piston 12, a spring 13, a connecting tube 14 and may further have a tool head 20 and a rear valve 30.

[0023]With further reference to FIGS. 7 and 8, the tube body 11 has an assembling hole 110, a bypass hole 111 and a sleeve 15. The assembling hole 110 is defined longitudinally through the tube body 11 and has a front opening 1101 and a rear opening 1102. The bypass hole 111 is defined transversely through the tube body 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressures | aaaaa | aaaaa |

| resetting force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com