Rivet gun

a rivet gun and riveting technology, applied in forging presses, manufacturing tools, forging press details, etc., can solve the problems of slow application of rivets and reduce the advantage of non-tapping varieties, and achieve the effect of reducing diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]Reference will now be made in detail to the presently preferred embodiments of the invention, examples of which are illustrated in the accompanied drawings.

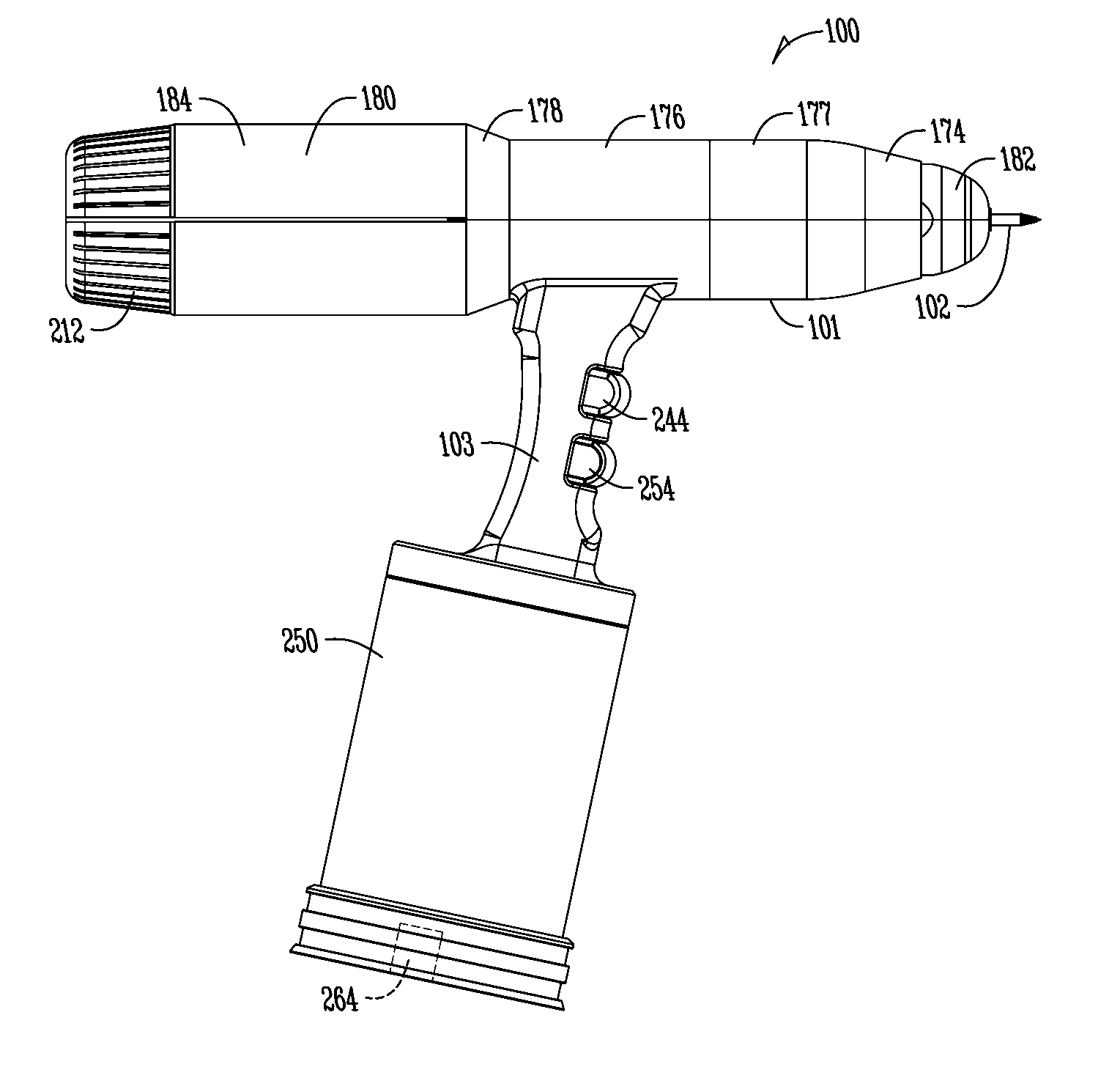

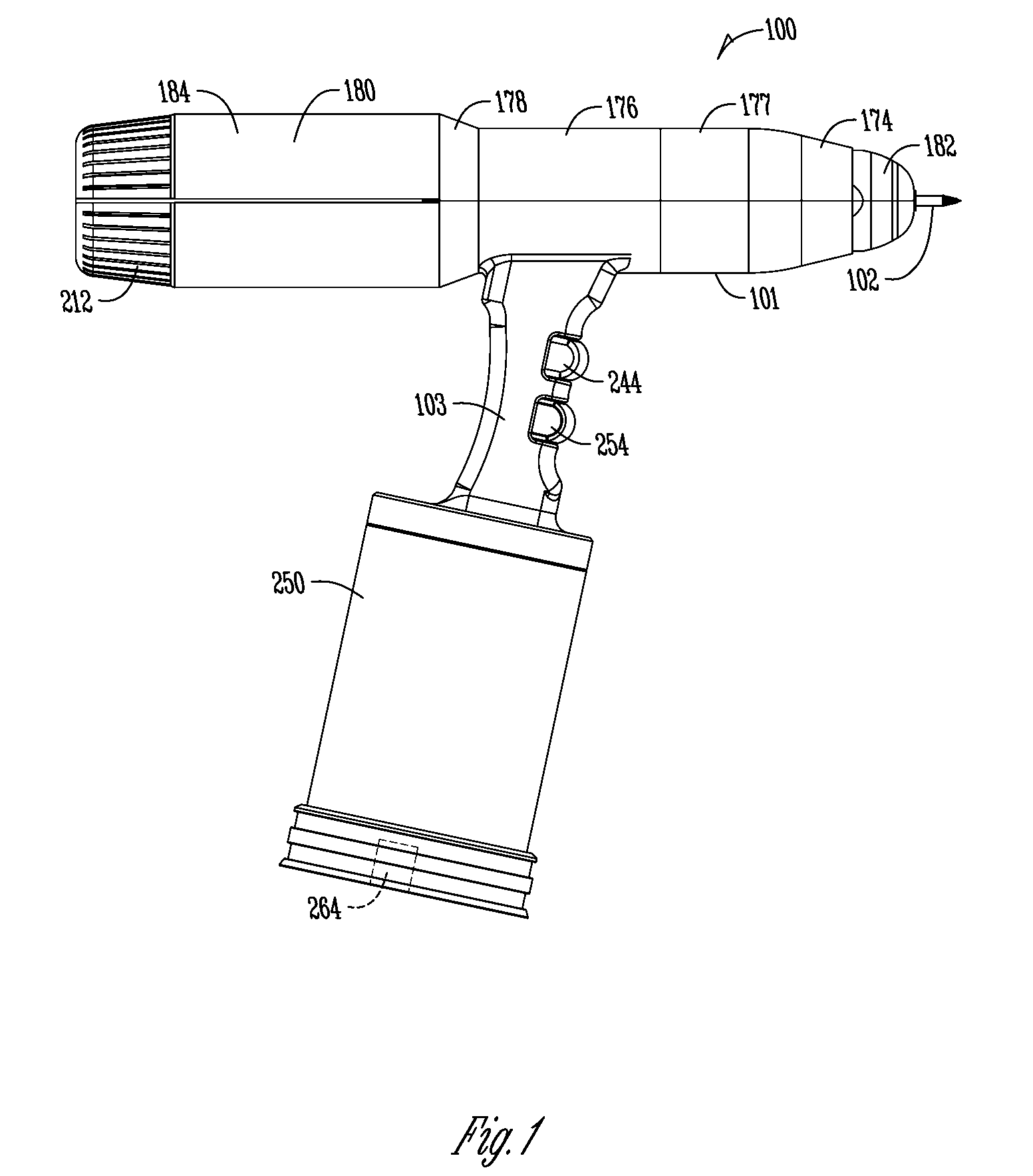

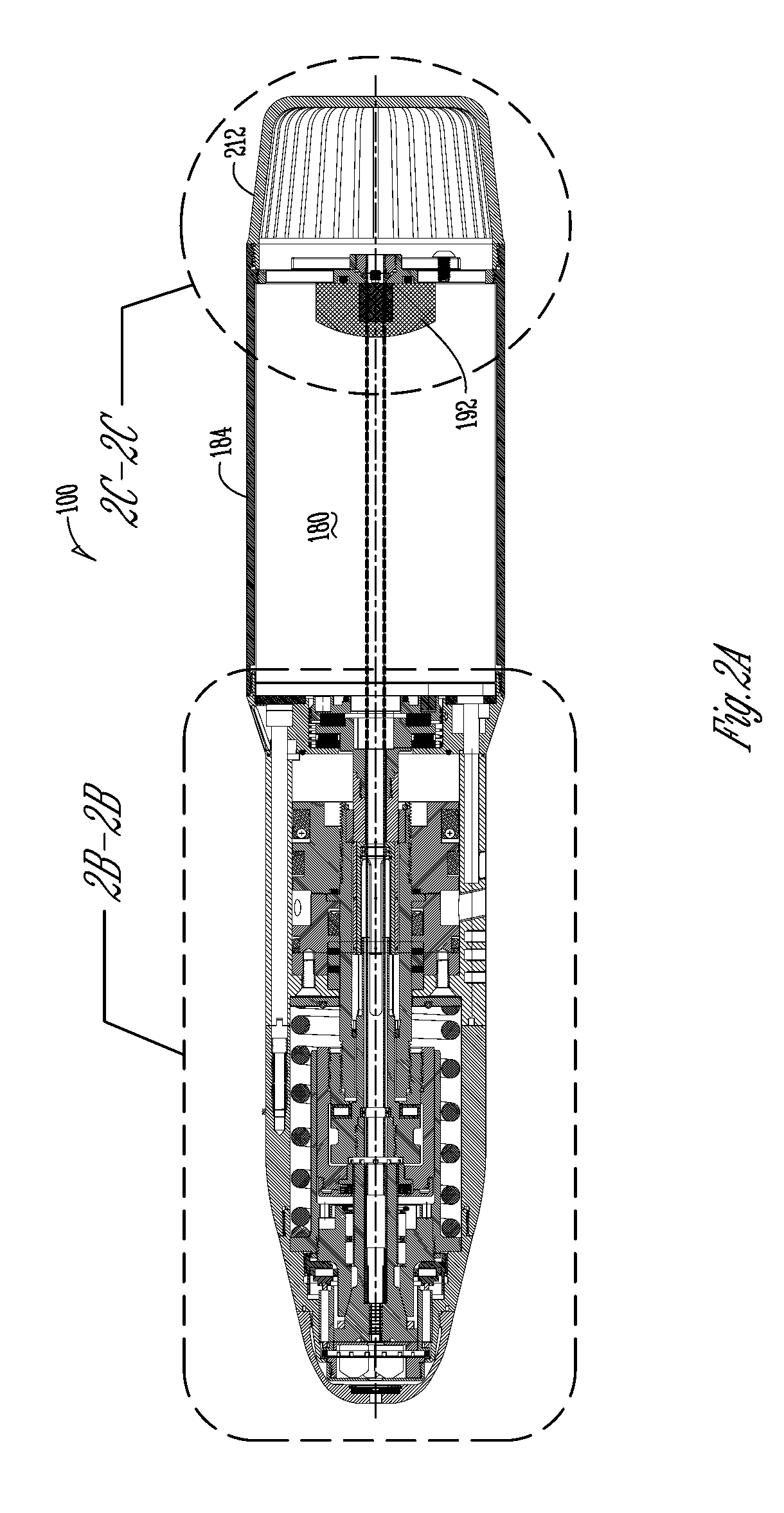

[0026]Referring generally to FIGS. 1-9B, a rivet gun 100 is described in accordance with an exemplary embodiment of the present invention. The rivet gun 100 is for setting a self-tapping rivet 102 in a work piece 112. An exemplary self-tapping rivet 102 includes a hollow rivet body 104 and a mandrel 106 extending longitudinally through the hollow rivet body 104. The mandrel 106 includes a self-tapping head 108 for forming a hole 114 in the work piece 112 and a shank 110, fixedly connected to the self-tapping head 108 for rotating the self-tapping head 108 and cutting through the work piece 112. After the self-tapping head 108 has passed through the hole 114 formed in the work piece 112, the hollow rivet body 104 is compressed and spread by the self-tapping head 108 as the mandrel 106 is retracted rearward relative to the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com